High-speed double-curved-surface polishing machine

A polishing machine and hyperboloid technology, applied in the direction of grinding/polishing equipment, optics, optical components, etc., can solve the problems of difficult adjustment, unreasonable structure, severe vibration of the whole machine, etc., and achieve the effect of improving the polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] As mentioned in the background art section, there are some disadvantages in the prior art of using grinding tools and polishing powders for regular grinding of lenses. For example: 1. The whole machine vibrates violently and makes a lot of noise. 2. The aperture adjustment is inconvenient or impossible to adjust, thus making the lens surface unqualified. 3. The down pressure of the mold is not quantitatively controlled, or the structure is unreasonable and difficult to adjust.

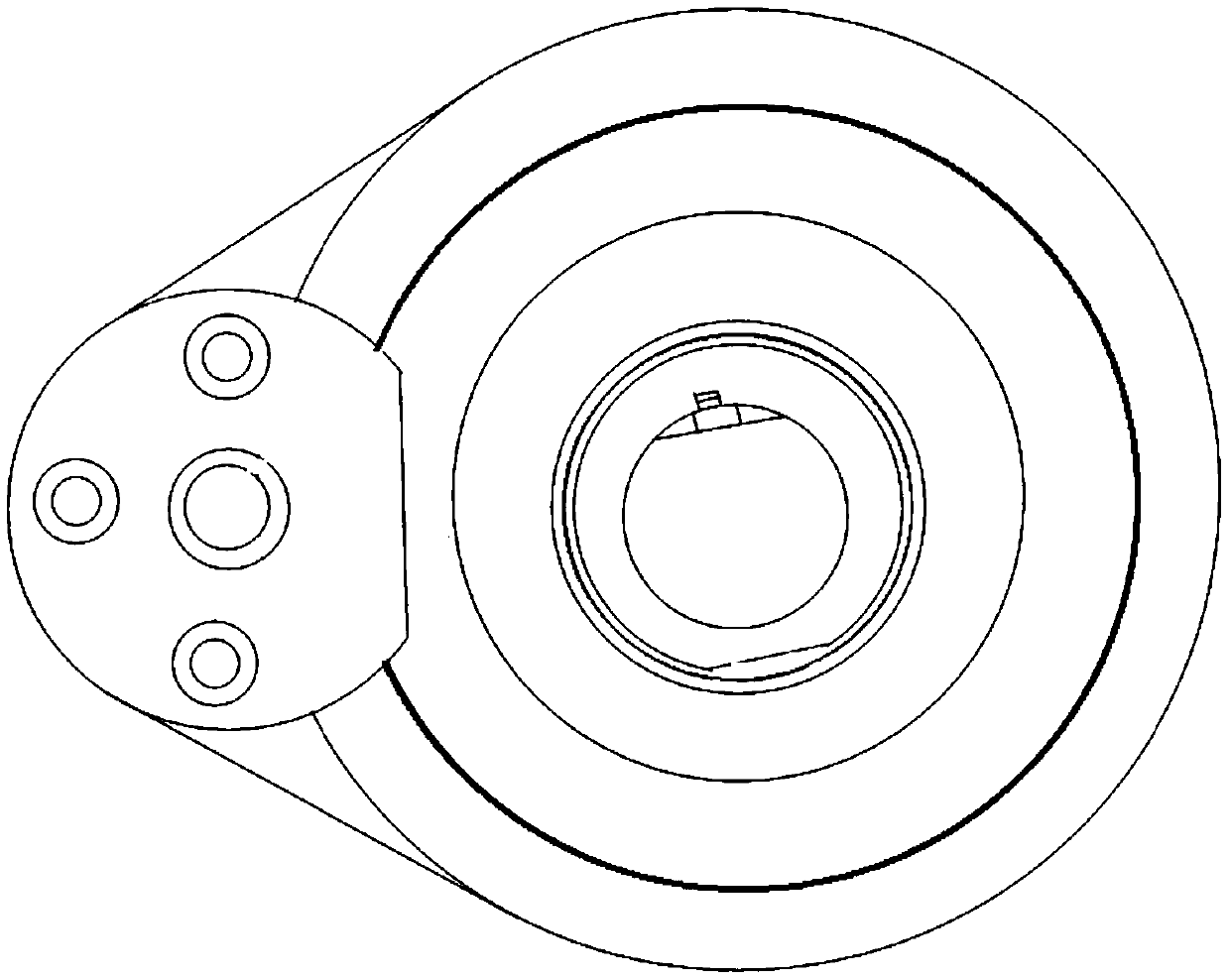

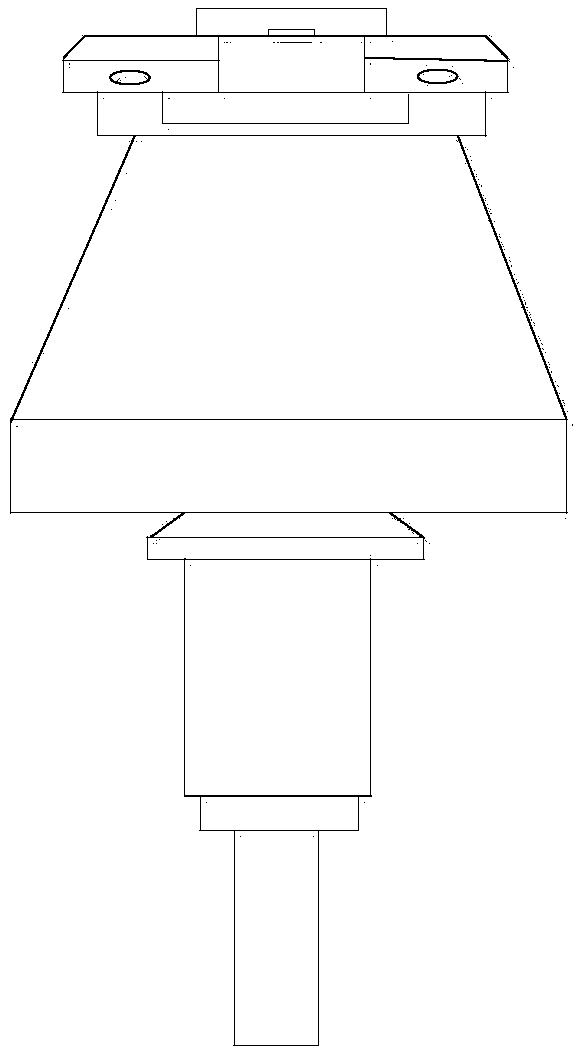

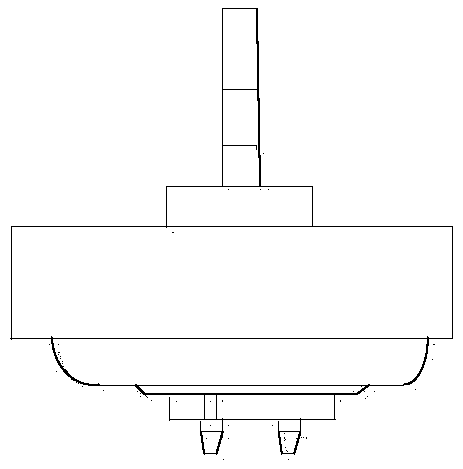

[0024] Based on this, an embodiment of the present invention provides a hyperboloid high-speed polishing machine, including a power component, a lens clamping base, and a grinding tool swing head. The power component includes a motor and an eccentrically adjustable planetary turbine for driving the The lens to be processed fixed by the lens clamping base swings eccentrically in a circle. The surface of the lens is polished.

[0025] To sum up, the hyperboloid high-speed polishing machine prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com