Fixing ring capable of automatically giving alarm when damaged

An automatic alarm and fixing ring technology, applied in the field of fixing rings, can solve problems such as damage to polishing head and polishing pad parts, wafer fragmentation, and large economic losses of the factory, so as to reduce potential risks and economic losses and facilitate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

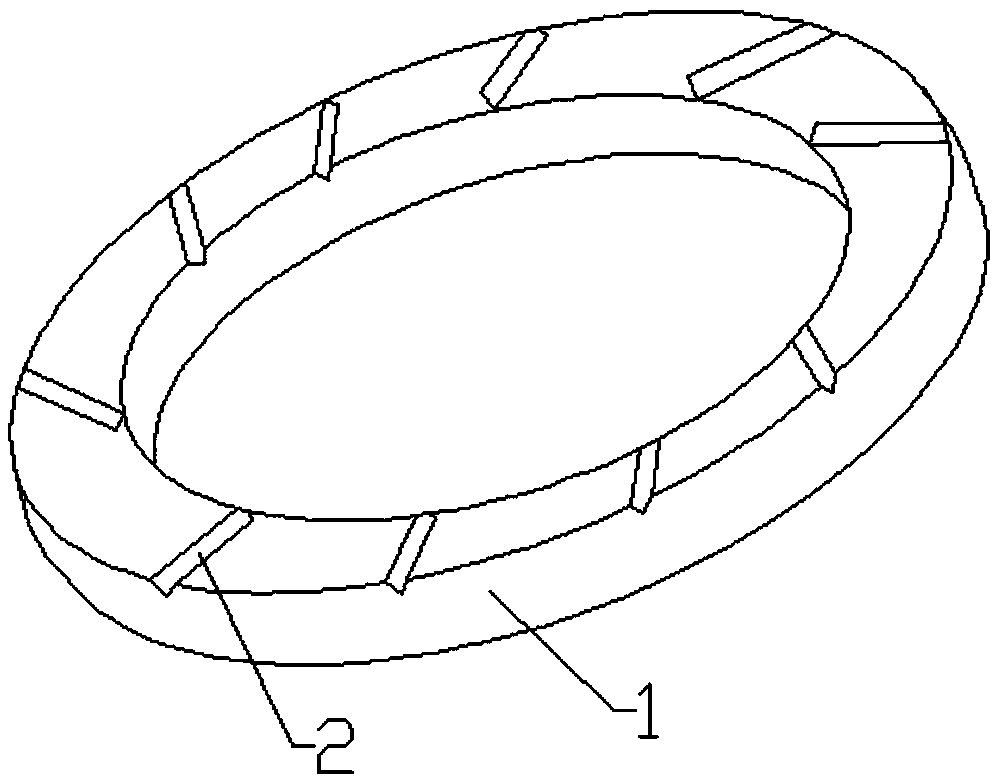

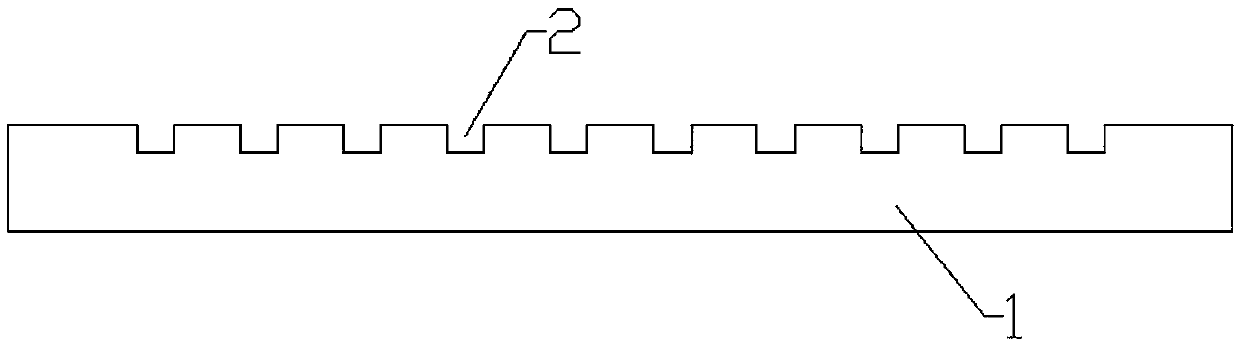

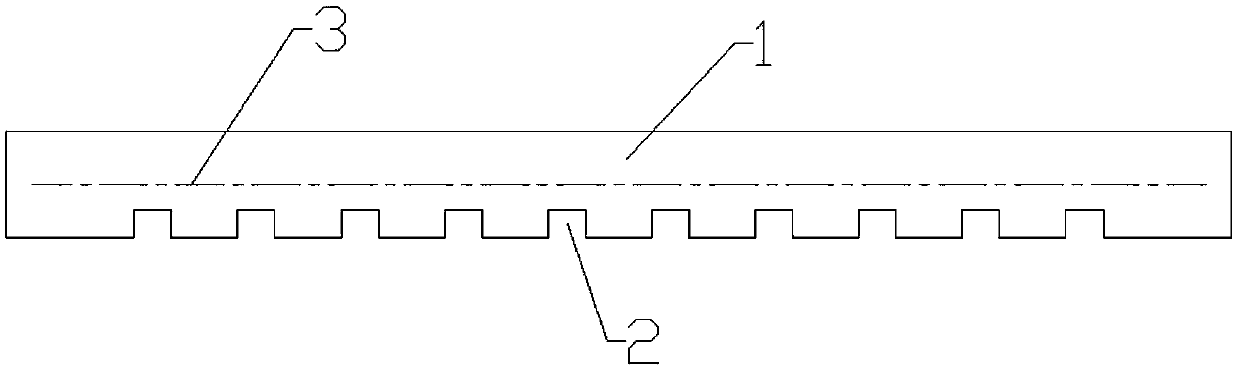

[0032] refer to Figure 2a , which is a side view of the fixed ring body of the embodiment of the fixed ring that can automatically alarm when it is damaged; Figure 2b , is a structural connection schematic diagram of Embodiment 1 of the fixing ring that can automatically alarm when damaged in the present invention.

[0033] As shown in the figure, compared with the fixed ring in the prior art, this embodiment includes a fixed ring body 1 with the same structure and function as the prior art, that is, the fixed ring body 1 is in the shape of a sheet-shaped ring as a whole, and the lower surface A plurality of grooves 2 are provided; at the same time, a ring-shaped thin wire 3 is embedded in the fixed ring body 1, and a resistance monitoring device 4 is connected to both ends of the ring-shaped thin wire 3, and the resistance monitoring device 4 detects the ring-shaped thin wire 3 in real time. resistance information, and the resistance detection device is electrically connec...

Embodiment 2

[0040] refer to Figure 3a , is the side view of the fixing ring body of the second embodiment of the fixing ring that can automatically alarm when it is damaged; Figure 3b , is a structural connection schematic diagram of Embodiment 2 of the fixing ring that can automatically alarm when damaged in the present invention.

[0041] As shown in the figure, compared with the fixed ring in the prior art, this embodiment includes a fixed ring body 1 with the same structure and function as the prior art, that is, the fixed ring body 1 is in the shape of a sheet-shaped ring as a whole, and the lower surface A plurality of grooves 2 are provided; at the same time, the inside of the fixed ring body 1 is inlaid with multiple ring wires 5, and the plane where each ring wire 5 is located is parallel to the plane where the upper surface of the fixed ring body is located. Numbering from bottom to top is No. 1, No. 2, No. 3, No. 4..., the two ends of each ring wire 5 are connected with a fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap