Chain hopper structure of chain hopper machine

A chain bucket machine and chain bucket technology, which is applied to conveyors, transportation and packaging, etc., can solve the problems of increased labor intensity of operators, reduced actual loading volume, and reduced work efficiency, and can save space and chain pitch. The effect of reducing and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

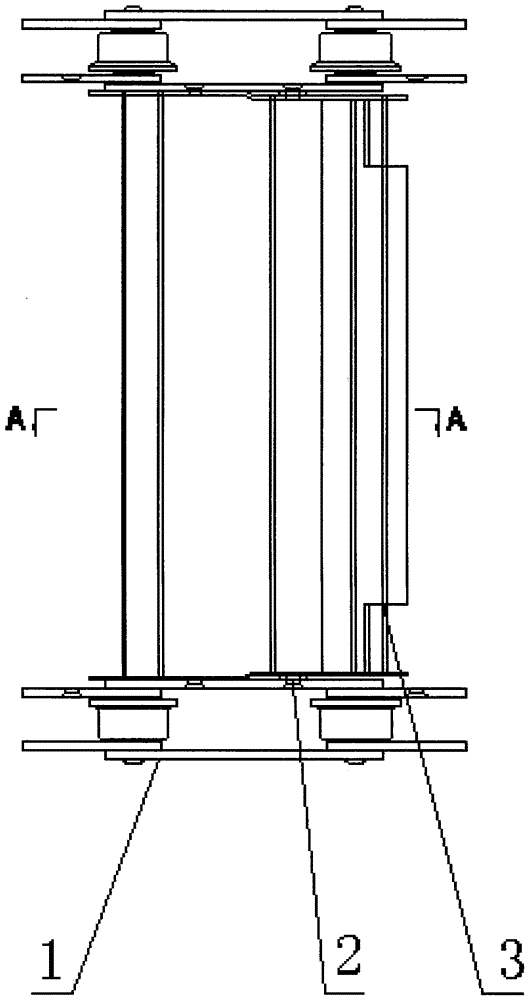

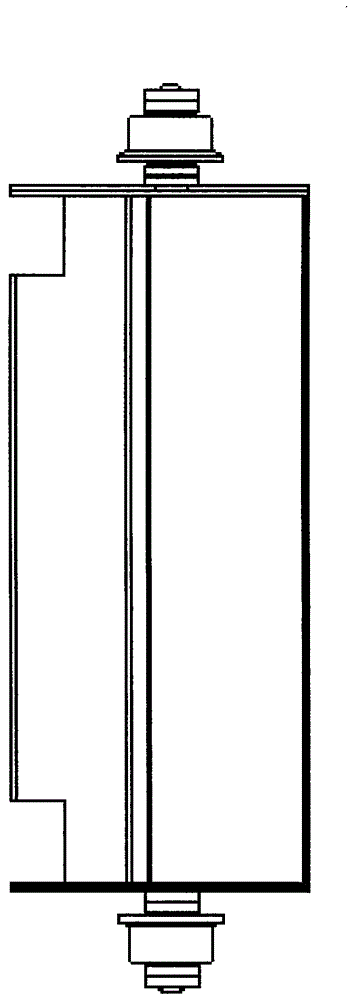

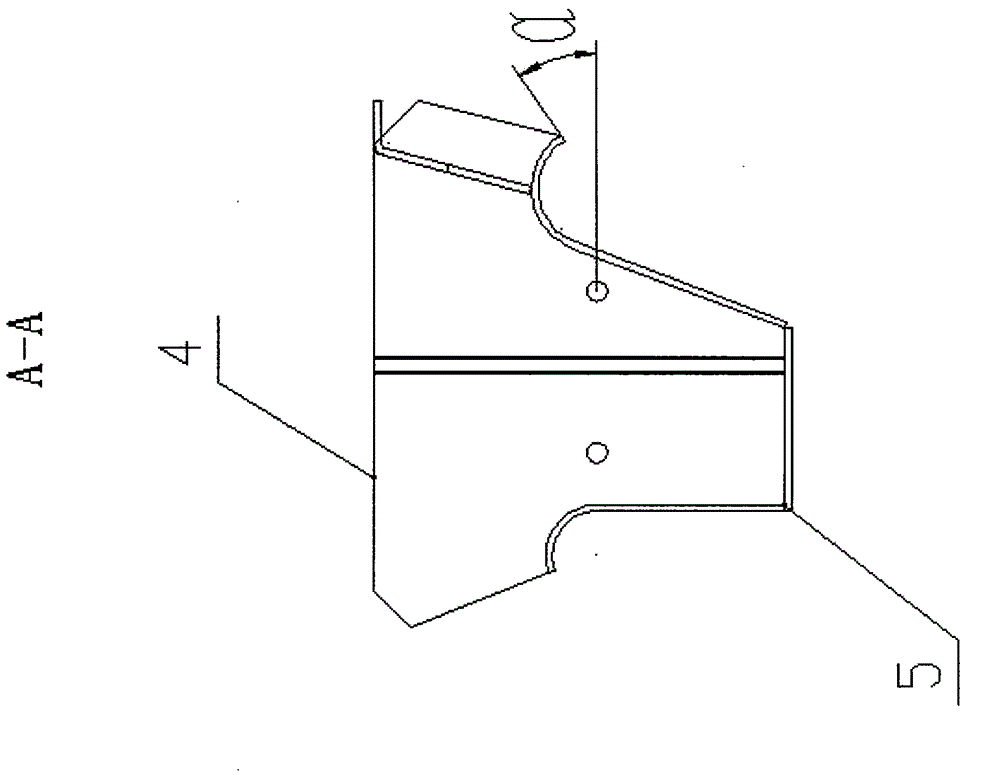

[0011] As shown in the figure, a chain bucket structure of a chain bucket machine includes a chain bucket 3 , a coupling piece 2 and a chain 1 . The pitch of chain 1 is small, and the pitch is less than or equal to 25cm; along the running direction of the chain, the forward inclination angle of the front end of the chain bucket is 68°, and the shape of the chain bucket 3 is deepened, and the ratio of length, width and height is 3:1:2. The mouth 4 of the bucket is larger than the bottom 5; the chain bucket adopts a scale-plate lap joint structure.

[0012] When the chain bucket is unloading, it needs to be straightened, and special fixtures are used for welding. During assembly, the chain 1 and the chain bucket 3 are connected through the coupling piece 2 . When the chain moves, the chain bucket loaded with materials also continuously conveys the materials forward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com