Automatic feeding device for projectile propellant preparation

A technology of automatic feeding and propellant, applied in explosives, offensive equipment, explosives processing equipment, etc., can solve the problems of increased difficulty and high viscosity of automatic operation, avoid blockage, realize rolling pressure and rolling height space, and realize freedom effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

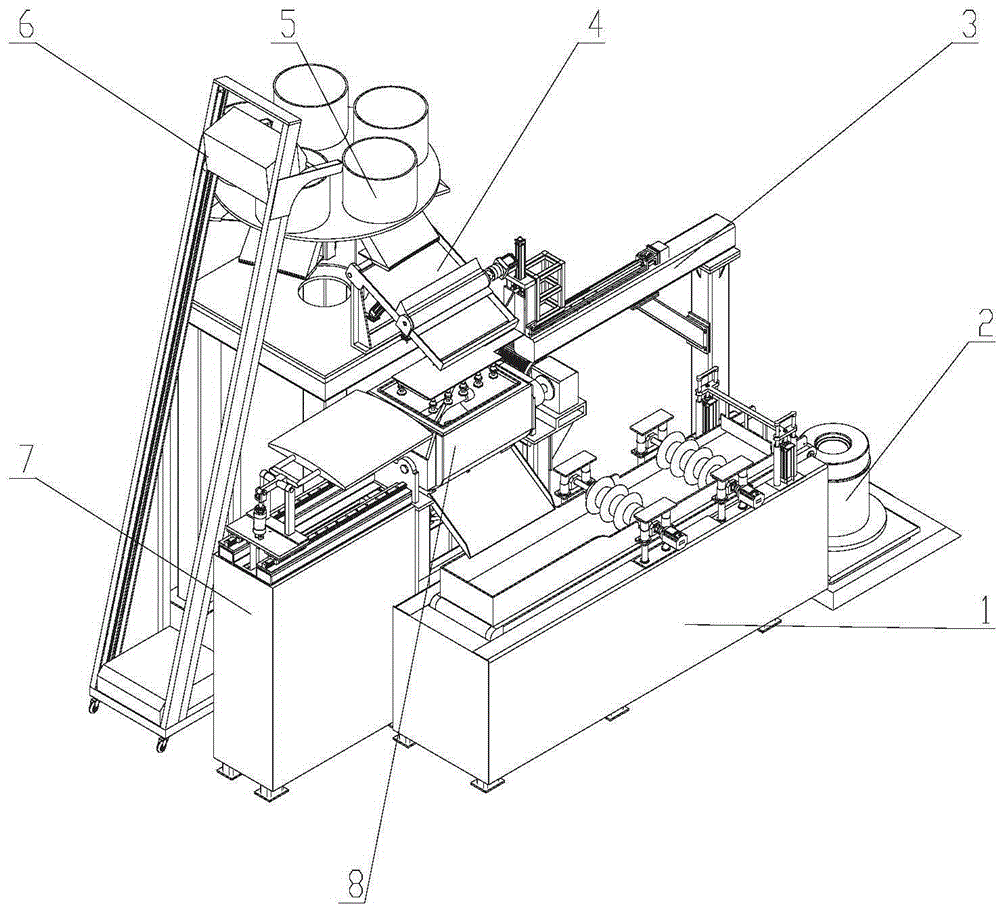

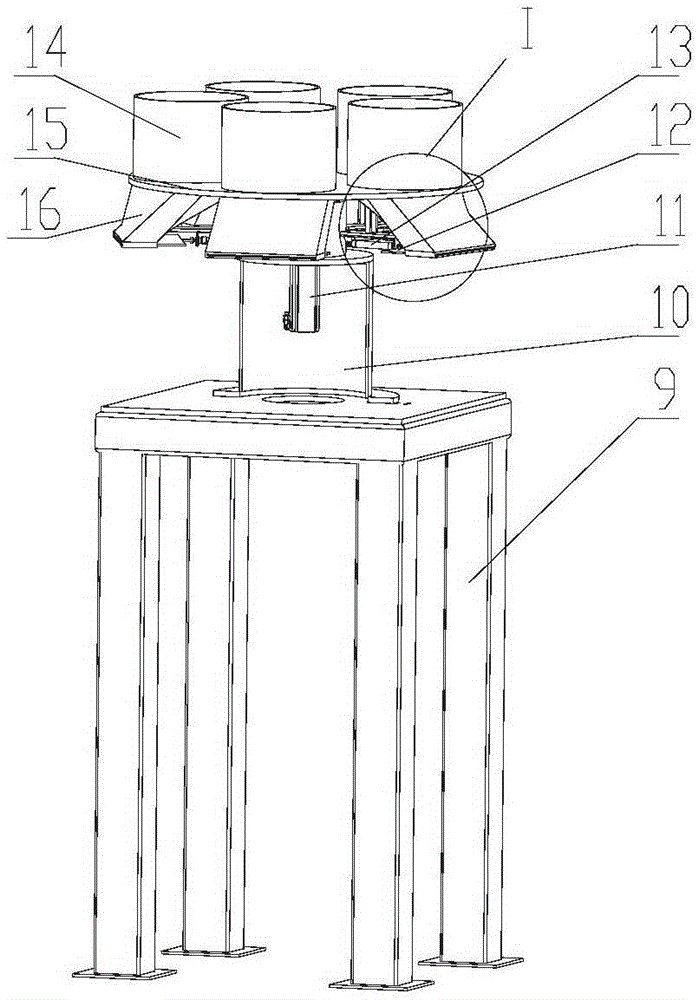

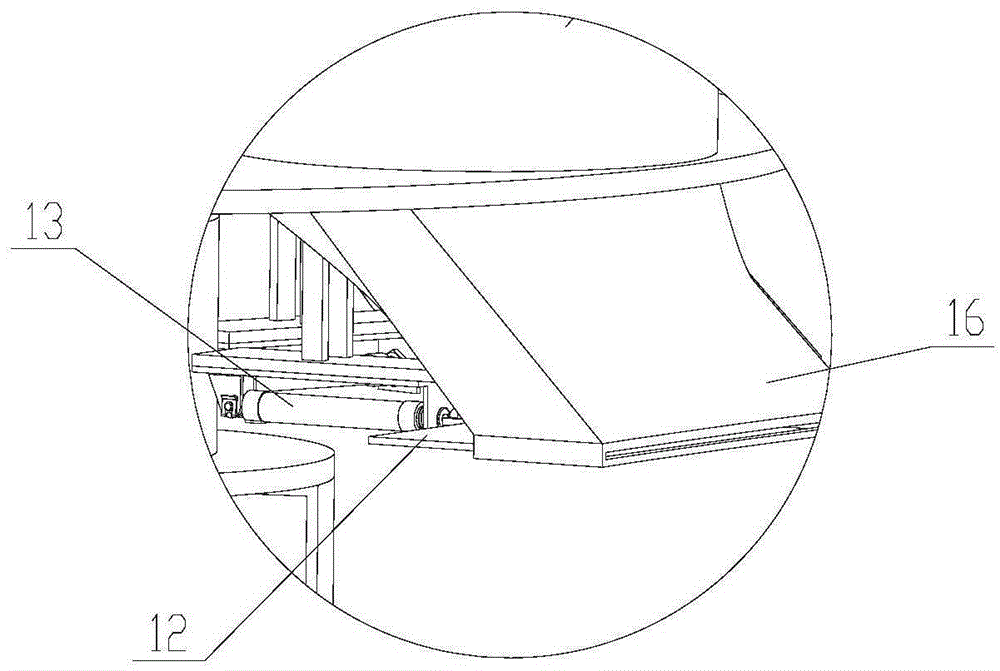

[0036] Such as figure 1 As shown, an automatic feeding device for preparing shell propellant provided by the present invention includes a hoist 6, a rotating feeding device 5, a feeding flat device 4, a kneading device 8, a solvent delivery device 3, a crushing delivery device 1 and Screening cylinder 2, wherein the rotary feeding device 5, the solvent conveying device 3 and the pulverizing conveying device 1 are arranged on the outside of the kneading device 8 along the circumferential direction, and the feeding flat device 4 is arranged on the rotating feeding device 5 and the kneading device 8 and is fixedly connected with the kneading device 8, the hoist 6 is located on one side of the rotary feeding device 5, and is used to feed the rotary feeding device 5, and the pulverizing conveying device 1 is connected with the screening cylinder 2 .

[0037] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com