TPE pulling force pipe material and preparation method thereof

A technology of tension and tube material, which is applied in the field of TPE tension tube material and its preparation, can solve the problems of upper temperature limit, solvent resistance, oil resistance, large compression deformation, high density, etc., and achieve high strength, high elastic strength, and weather resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

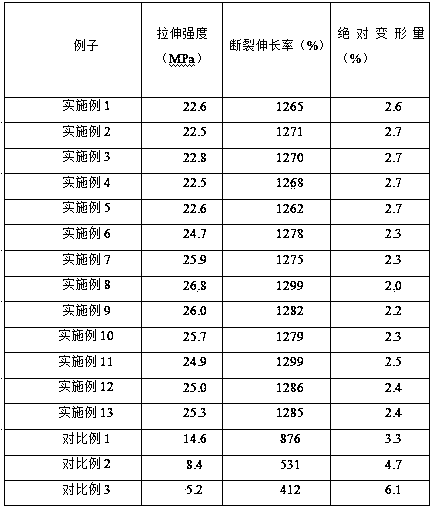

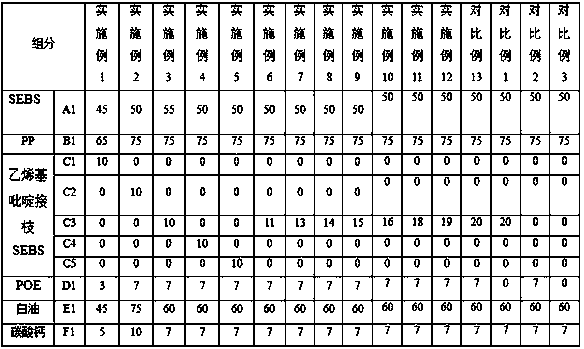

Examples

Embodiment approach

[0046]In the present application, the PP is a polypropylene resin, which includes at least one of homopolypropylene, copolymerized polypropylene and random copolymerized polypropylene. The addition of polypropylene resin can make the molecular chain of SEBS rubber resin more flexible, thereby increasing the elasticity of the product, making it have a soft feel and mechanical performance. In addition, polypropylene also has strong resistance to chemical attack, thereby improving the chemical corrosion resistance of SEBS thermoplastic elastomers. PP is cheap and can reduce the cost of using SEBS. During the experiment of the applicant, homopolypropylene has better compatibility with vinylpyridine-grafted SEBS and better mechanical properties than copolypropylene and random polypropylene. As a preferred embodiment of the present invention, the PP is homopolypropylene with a melt index of 8.6.

[0047] Vinylpyridine-grafted SEBS

[0048] The term "vinylpyridine-grafted SEBS" ...

Embodiment approach 1

[0071] Embodiment 1, TPE tension pipe material, the TPE tension pipe material is prepared from raw materials including the following parts by weight:

[0072] SEBS45-55 copies

[0073] PP65-80 copies

[0074] Vinylpyridine graft SEBS10-20 parts

[0075] POE1-13 copies

[0076] 45-75 parts of white oil.

Embodiment approach 2

[0077] Embodiment 2 is the same as Embodiment 1, except that the SEBS is in powder form, and the degree of hydrogenation is >95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com