Preparation method for plastic particles filling anti-aging artificial lawn

A technology of plastic granules and artificial turf, which is applied in the field of preparation of anti-aging artificial turf filling plastic granules, which can solve problems such as economic loss, inability to synchronize life spans, and inconvenience for customers, so as to prolong service life, avoid product replacement, and reduce maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

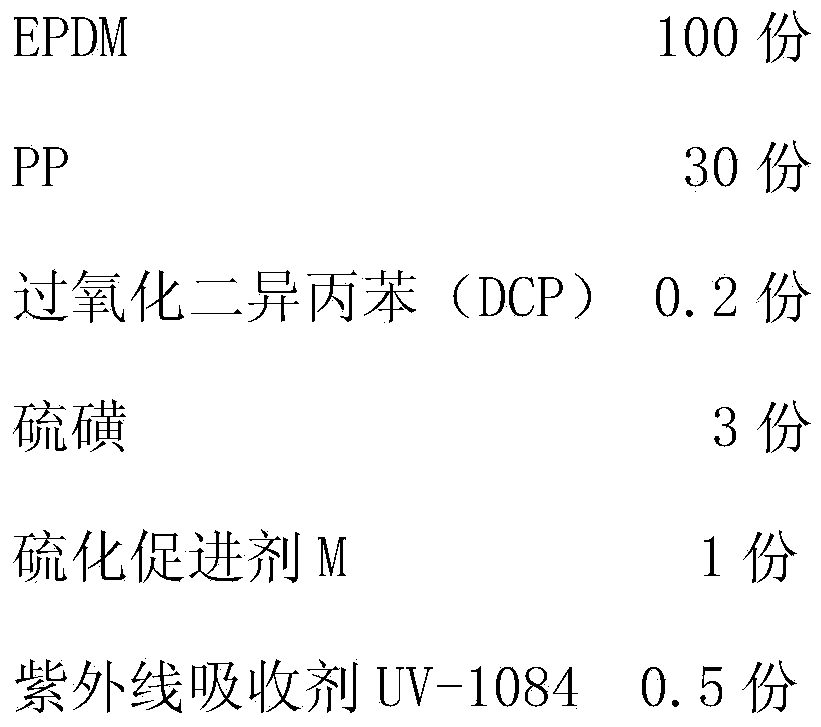

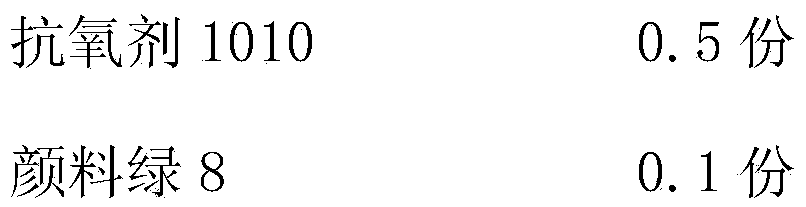

[0014] (1) Plastic granules for filling anti-aging artificial turf (by mass parts):

[0015]

[0016]

[0017] (2) Premix

[0018] Add EPDM, sulfur, and vulcanization accelerator M into an internal mixer and stir for 10 minutes at room temperature. After stirring evenly, press into tablets and cut into small pieces to obtain EPDM premix.

[0019] (3) EPDM premix and PP, DCP, ultraviolet absorber UV-1084, antioxidant 1010, and pigment green 8 were fully mixed for 10 minutes through a high-mixer, and then added to an extruder at 220 degrees Celsius to melt and extrude granules to obtain Plastic granules for anti-aging artificial turf filling.

Embodiment 2

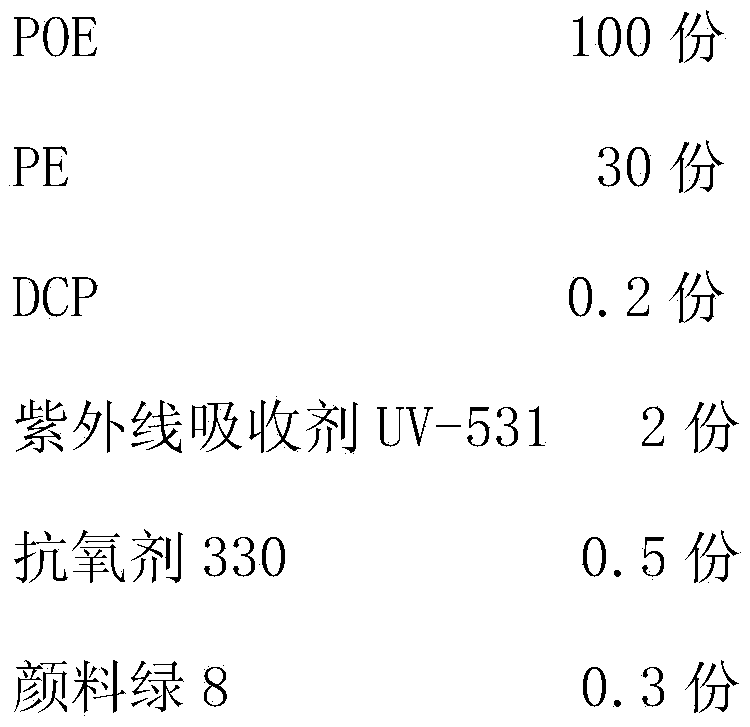

[0021] (1) Plastic granules for filling anti-aging artificial turf (by mass parts):

[0022]

[0023] (2) Mixing and granulation

[0024] Mix POE, PE, DCP, ultraviolet absorber UV-531, antioxidant 330, and pigment green 8 through a high-mixer for 10 minutes, then add them to the extruder to melt and extrude at 180 degrees Celsius to obtain anti-aging artificial turf Plastic pellets for filling.

Embodiment 3

[0026] (1) Plastic granules for filling anti-aging artificial turf (by mass parts):

[0027]

[0028]

[0029] (2) Premix

[0030] Add SBS, sulfur, and vulcanization accelerator M to an internal mixer and stir for 10 minutes at room temperature. After stirring evenly, press into tablets and cut into small pieces to obtain the SBS premix.

[0031] (3) Mix the SBS premix with HDPE, BPO, ultraviolet absorber UV-1084, antioxidant DLTP, and olive green through a high-mixer for 10 minutes, and then add it to the extruder at 210 degrees Celsius to melt, extrude and granulate to obtain anti-aging Plastic granules for aging artificial turf filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com