Pollution resistant matting aqueous paint composition and forming method thereof

A pollution-resistant, water-based coating technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as coating film pollution, and achieve excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In addition, "parts" and "%" in the following examples mean "parts by mass" and "% by mass", respectively.

[0101] Manufacture of water-based resin

manufacture example 1

[0103] 350 parts of deionized water and 10 parts of Newcol 707SF (Note 1) were added to a reaction vessel equipped with a thermometer, a thermostat, a stirrer, and a dropping device, stirred and mixed in a nitrogen stream, and the temperature was raised to 85°C. Next, 3% of the pre-emulsion part and 80 parts of 2.5% ammonium persulfate aqueous solution which emulsified the component of the following composition were added in reaction container, and it held at 85 degreeC for 20 minutes.

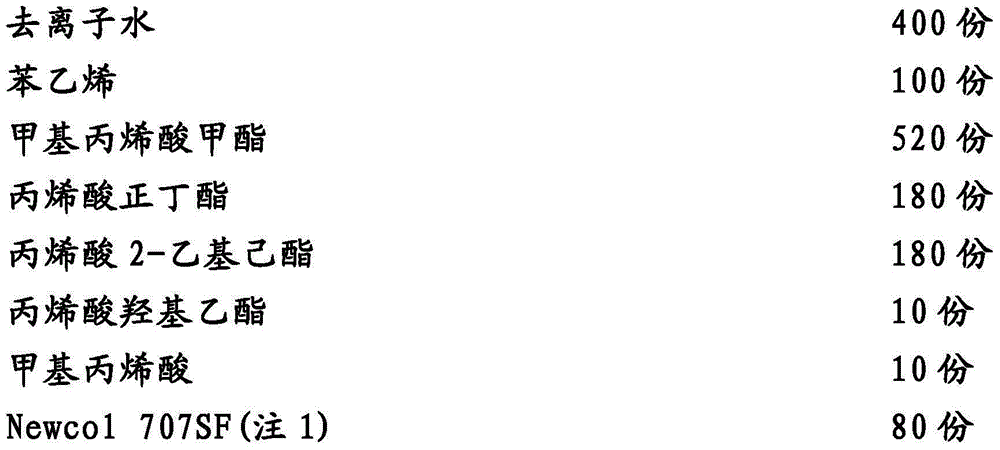

[0104]

[0105] Then, the remaining pre-emulsion and 80 parts of 2.5% ammonium persulfate aqueous solution were dripped in the reaction container over 4 hours, and aging was performed for 2 hours after the dropwise addition was completed. Then, it cooled to 30 degreeC, and adjusted so that the solid content may be 47 % and pH may become 8.0 using ammonia water and deionized water. Next, it discharged|emitted while filtrating with the nylon cloth of 200 meshes, and obtained the water-based r...

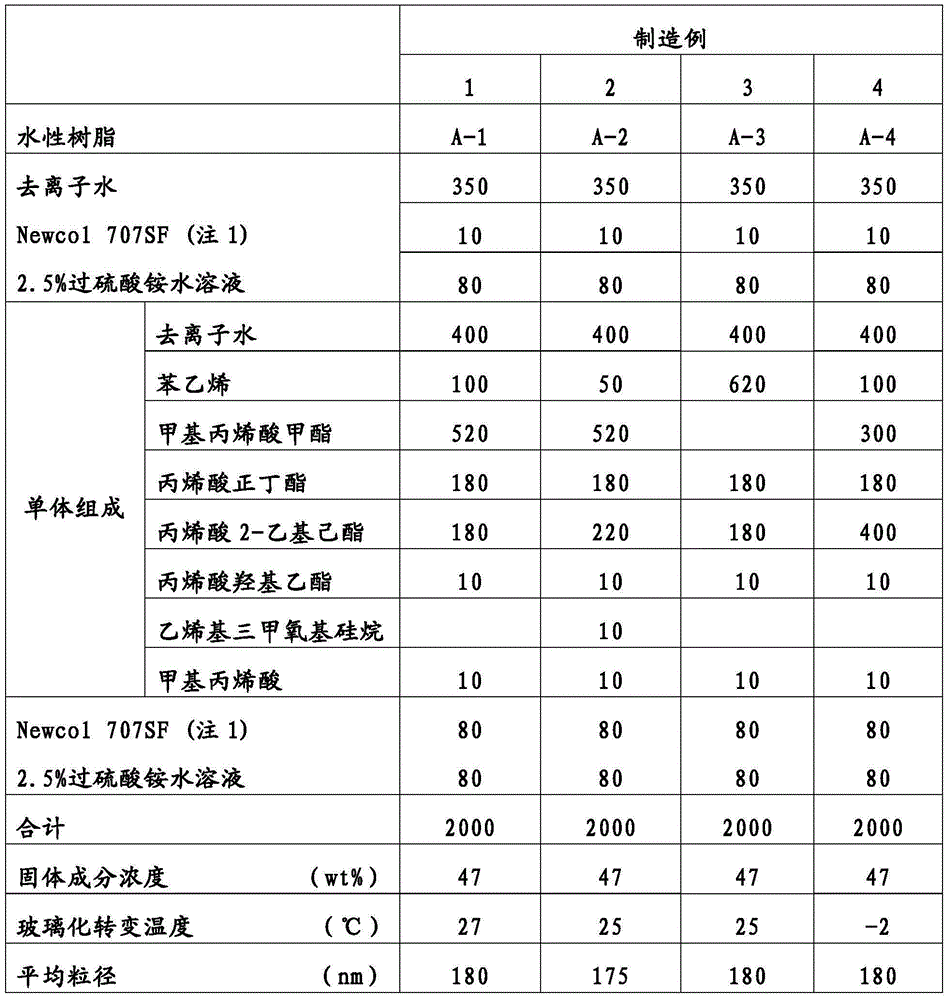

manufacture example 2~4

[0108] In said manufacture example 1, except having made the monomer composition into the compounding shown in following Table 1, it synthesize|combined similarly to manufacture example 1, and obtained water-based resin (A-2) - (A-4).

[0109] [Table 1]

[0110]

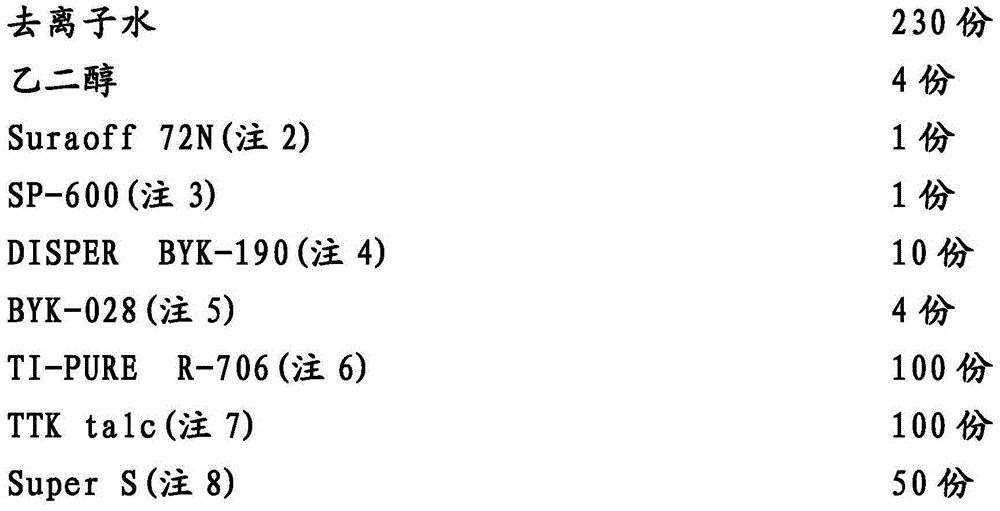

[0111] Manufacture of White Pigment Component Dispersion Paste

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com