Kitchen waste treatment method

A technology of kitchen waste and treatment method, which is applied in the direction of liquid carbon-containing fuel, recovery of fat oil/fatty acid from waste, fatty acid production, etc., can solve the problems such as the inability to effectively separate small residues, the inability to decompose fiber products, and the inconvenience of subsequent processing. , to avoid low fertilizer efficiency, facilitate subsequent processing, and shorten fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

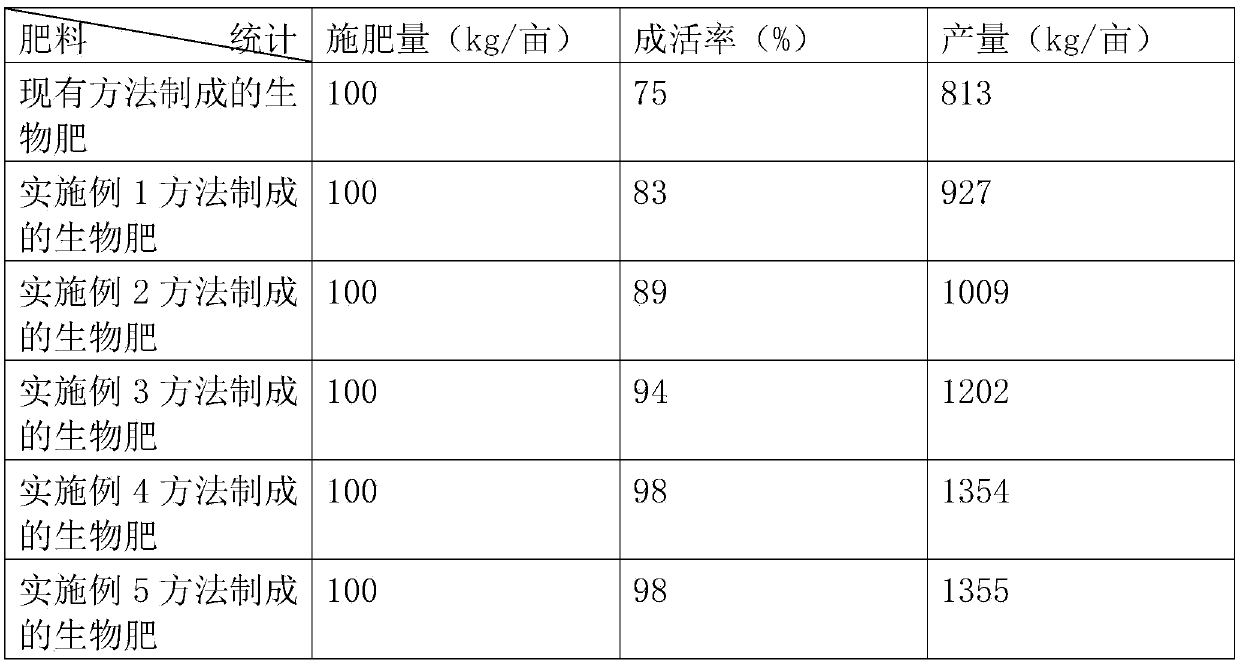

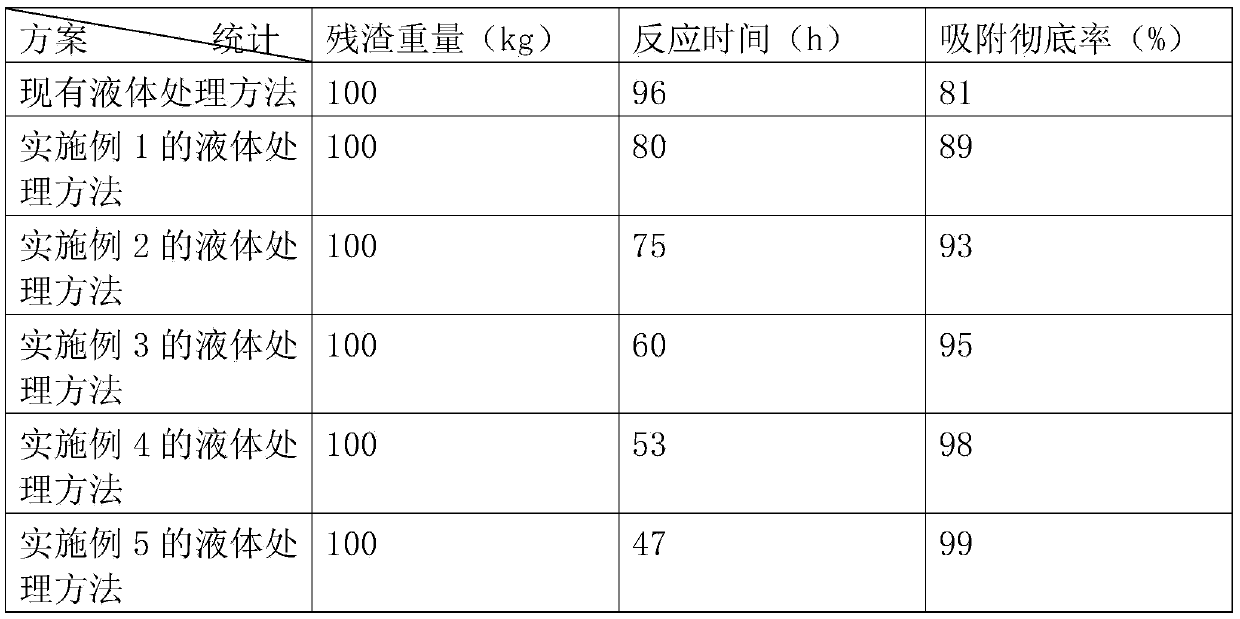

Examples

Embodiment 1

[0030] The disposal method of kitchen waste includes the disposal method of residue and the disposal method of liquid.

[0031] The kitchen waste is filtered into residues and liquids, the liquids are made into biodiesel, and the residues are made into biofertilizers.

[0032] The treatment method of the residue is as follows: after 100kg of residue is pulverized to 15mm, the pH of the mixture is adjusted to 5.5, then 7kg of bulking agent is added and mixed evenly; the water content of the mixture is measured and adjusted to be 48%; Liquid, multi-bacteria mixed solution is prepared by mixing 3 million cfu / ml white rot bacteria, 3 million cfu / ml lactic acid bacteria, 3 million cfu / ml white rot bacteria, 3 million cfu / ml Aspergillus niger; at a temperature of 40 ° C, ventilation Fermentation was carried out for 42h under the conditions, and the ventilation rate was 4L / min; 1.19kg of potassium dihydrogen phosphate was added and mixed evenly to obtain biological fertilizer.

[00...

Embodiment 2

[0036] The treatment method of the residue is as follows: after crushing 100kg of residue to 20mm, adjust the pH of the mixture to 5.6, then add 8kg of bulking agent and mix it evenly; measure and adjust the water content of the mixture to be 50%; then add 11.05kg of multi-bacteria to mix Liquid, multi-bacteria mixed solution is prepared by mixing 3 million cfu / ml white rot bacteria, 3 million cfu / ml lactic acid bacteria, 3 million cfu / ml white rot bacteria, 3 million cfu / ml Aspergillus niger; at a temperature of 45 ° C, ventilation Fermentation was carried out for 44h under the conditions, and the ventilation rate was 5L / min; 1.46kg of potassium dihydrogen phosphate was added and mixed evenly to obtain biological fertilizer.

[0037] Among them, the bulking agent is prepared by mixing 2.64kg of manure, 0.48kg of sawdust and 4.88kg of sandy soil evenly.

[0038] The liquid treatment method is: pass 100kg of liquid through an ultrasonic pulverizer to pulverize the suspended mat...

Embodiment 3

[0040] The treatment method of the residue is as follows: after crushing 100kg of residue to 20mm, adjust the pH of the mixture to 6, then add 10kg of bulking agent and mix evenly; measure and adjust the water content of the mixture to be 55%; then add 12.5kg of multi-bacteria to mix Liquid, multi-bacteria mixed solution is prepared by mixing 3 million cfu / ml white rot bacteria, 3 million cfu / ml lactic acid bacteria, 3 million cfu / ml white rot bacteria, 3 million cfu / ml Aspergillus niger; at a temperature of 47 ° C, ventilation Fermentation was carried out for 46h under the conditions, and the ventilation rate was 6L / min; 1.88kg of potassium dihydrogen phosphate was added and mixed evenly to obtain biological fertilizer.

[0041] Wherein, the bulking agent is prepared by mixing 3kg of manure, 1.5kg of sawdust and 5.5kg of sand evenly.

[0042]The liquid treatment method is: pass 100kg of liquid through an ultrasonic pulverizer to pulverize the suspended matter in the liquid to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com