A production method of thin-gauge pickling and annealing tool steel

A production method and tool steel technology, applied in the field of tool steel manufacturing, can solve the problems affecting the fatigue resistance of tool steel, etc., and achieve the effects of improving production efficiency and profitability, improving single-pass reduction rate and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

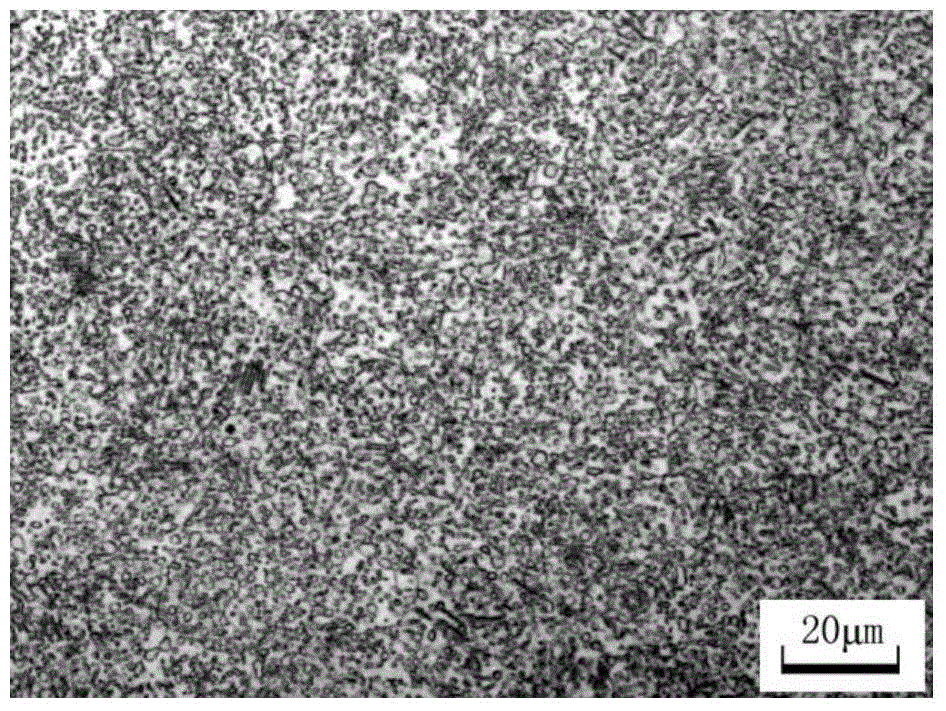

Embodiment 1

[0037] What the present embodiment produces is tool steel SK95, and its production steps are:

[0038] (1) Converter smelting: adopt 150t converter smelting;

[0039] (2) LF refining: LF refining is used after converter smelting. The main chemical components of the refined molten steel are C: 0.95wt.%, Si: 0.20wt.%, Mn: 0.15wt.%, P: 0.015wt.%, S: 0.003wt.%, Cr: 0.15wt.%, the rest are Fe and unavoidable impurities;

[0040] (3) Continuous casting: continuous casting after LF refining, control casting speed to 5.0m / min, superheat of molten steel to 11°C, casting slab liquid core depression to 10mm;

[0041] (4) Soaking: the slab is soaked, the temperature of the slab entering the furnace is 1050°C, the control soaking temperature is 1150°C, and the soaking time is 30min;

[0042] (5) continuous hot rolling: the slab after soaking is carried out hot continuous rolling, and the control finish rolling temperature is 880 ℃;

[0043] (6) Cooling: cooling the slab after hot continu...

Embodiment 2

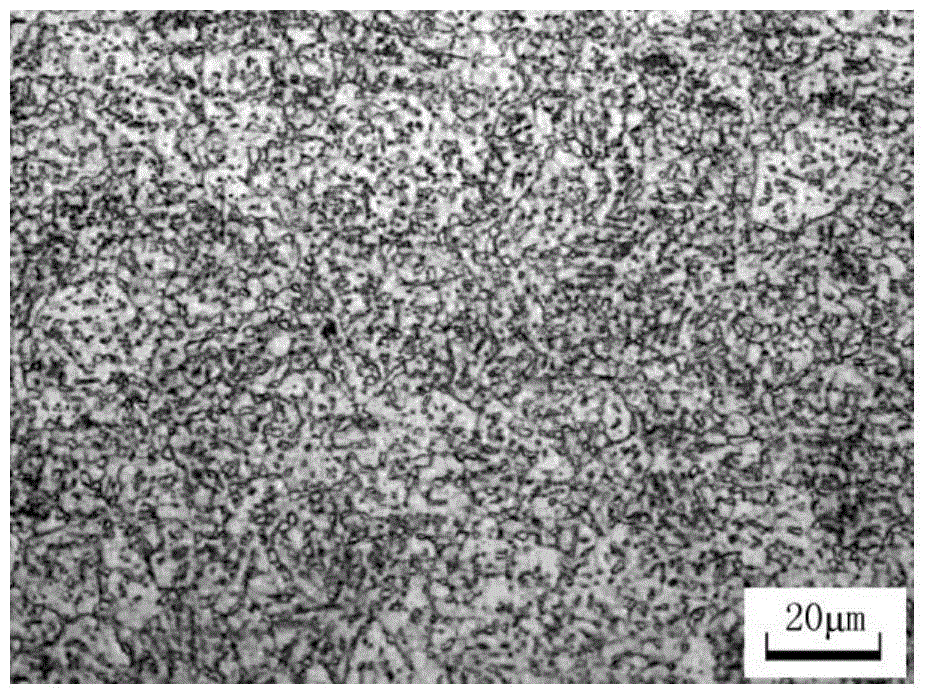

[0053] What the present embodiment produces is the production method of tool steel SK85, and its production steps are:

[0054] (1) Converter smelting: adopt 150t converter smelting;

[0055] (2) LF refining: LF refining is used after converter smelting. The main chemical components of the refined molten steel are C: 0.85wt.%, Si: 0.30wt.%, Mn: 0.40wt.%, P: 0.018wt.%, S: 0.04wt.%, Cr: 0.40wt.%, the rest are Fe and unavoidable impurities;

[0056] (3) Continuous casting: continuous casting after LF refining, control casting speed to 3.6m / min, superheat of molten steel to 29°C, casting slab liquid core depression to 19mm;

[0057] (4) Soaking: the slab is soaked, the slab entering furnace temperature is 850°C, the soaking temperature is 1165°C, and the soaking time is 34min;

[0058] (5) continuous hot rolling: the slab after soaking is carried out hot continuous rolling, and the control finish rolling temperature is 855 ℃;

[0059] (6) Cooling: cooling the slab after hot con...

Embodiment 3

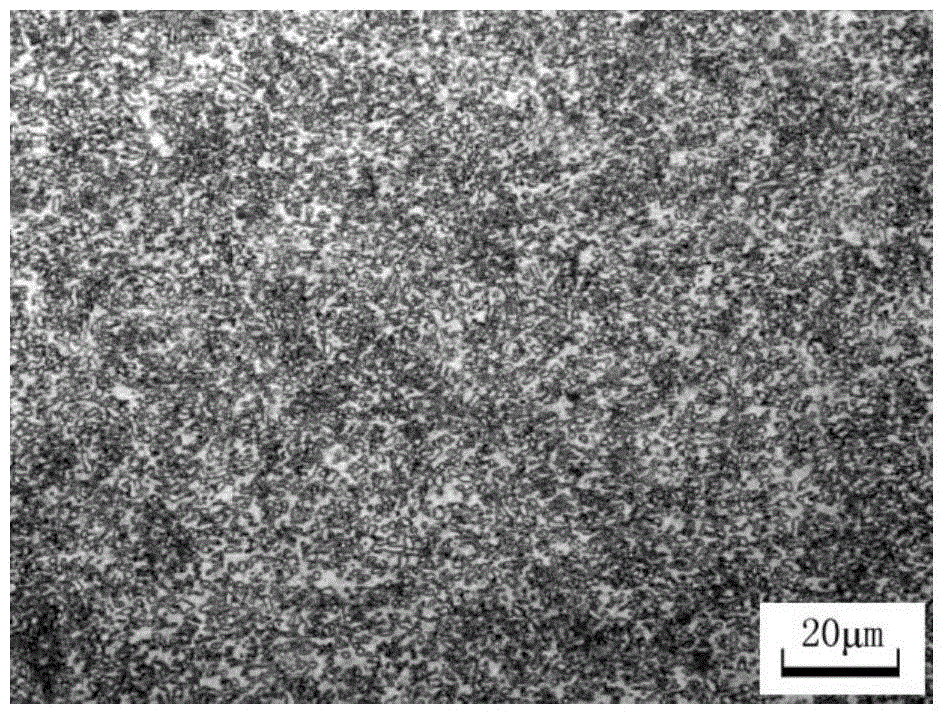

[0069] What the present embodiment produces is the production method of tool steel C75S, and its production steps are:

[0070] (1) Converter smelting: adopt 150t converter smelting;

[0071] (2) LF refining: LF refining is used after converter smelting. The main chemical components of the refined molten steel are C: 0.75wt.%, Si: 0.25wt.%, Mn: 0.45wt.%, P: 0.015wt.%, S: 0.005wt.%, Cr: 0.20wt.%, the rest are Fe and unavoidable impurities;

[0072] (3) Continuous casting: continuous casting after LF refining, control casting speed to 3.9m / min, superheat of molten steel to 24°C, casting slab liquid core depression to 16mm;

[0073] (4) Soaking: the slab is soaked, the temperature of the slab entering the furnace is 1000°C, the control soaking temperature is 1125°C, and the soaking time is 29min;

[0074] (5) continuous hot rolling: the slab after soaking is carried out hot continuous rolling, and the control finish rolling temperature is 869 ℃;

[0075] (6) Cooling: cooling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com