Cold firework jetting equipment

A technology for equipment and fireworks, applied in the field of cold fireworks eruption equipment, can solve the problems of inability to recycle cold fireworks, pollution by smoke and irritating odor, uncontrollable eruption time, etc., and achieves simple structure, long eruption time, and compact device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and example.

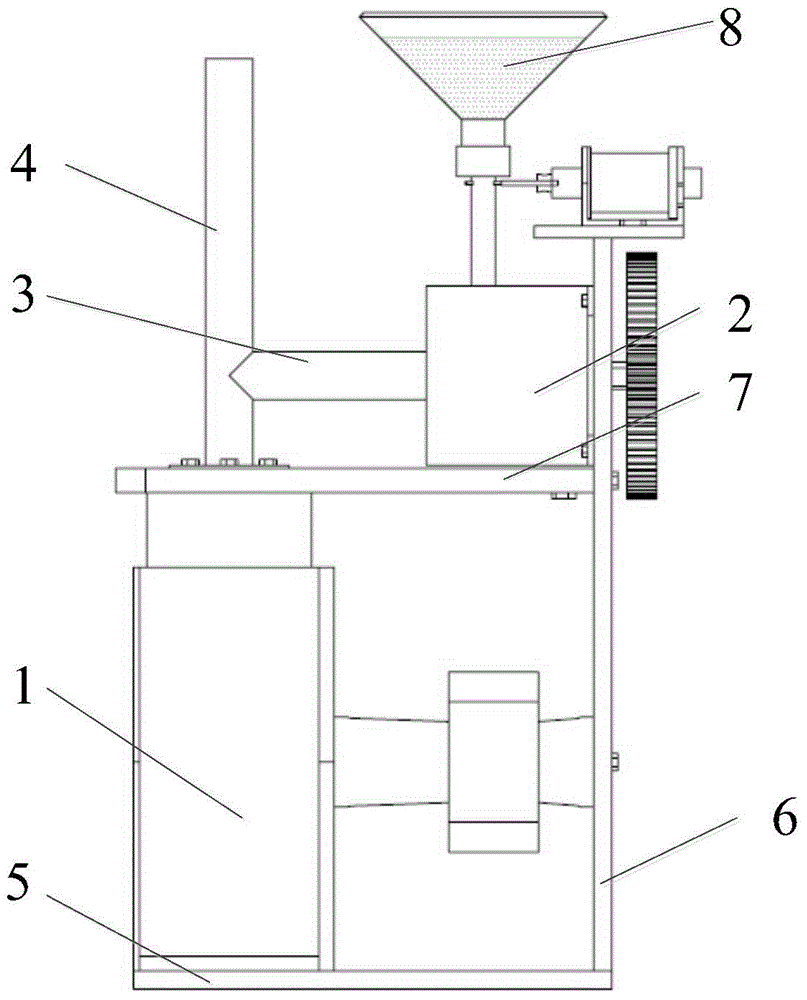

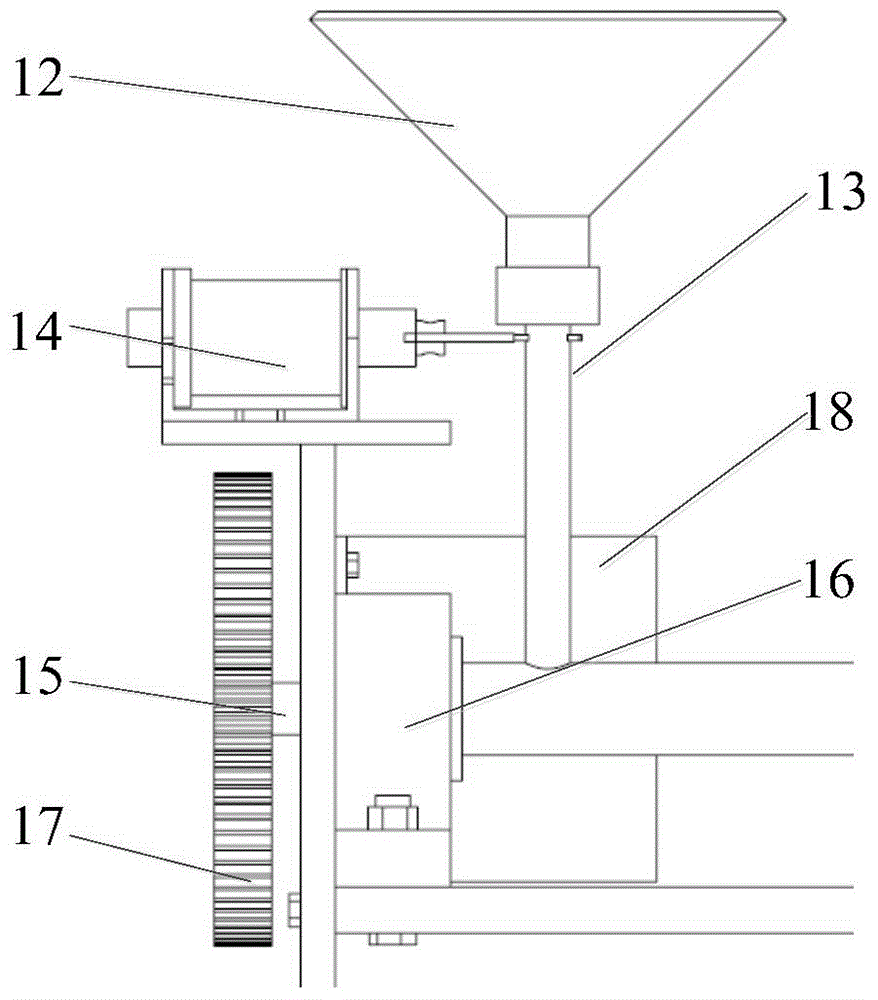

[0029] like figure 1 As shown, the overall structure of the device includes: air supply device 1, feeding device 2, heating device 3, cold pyrotechnic nozzle 4, bottom support plate 5, side support plate 6, cold pyrotechnic nozzle mounting plate 7 and metal powder 8.

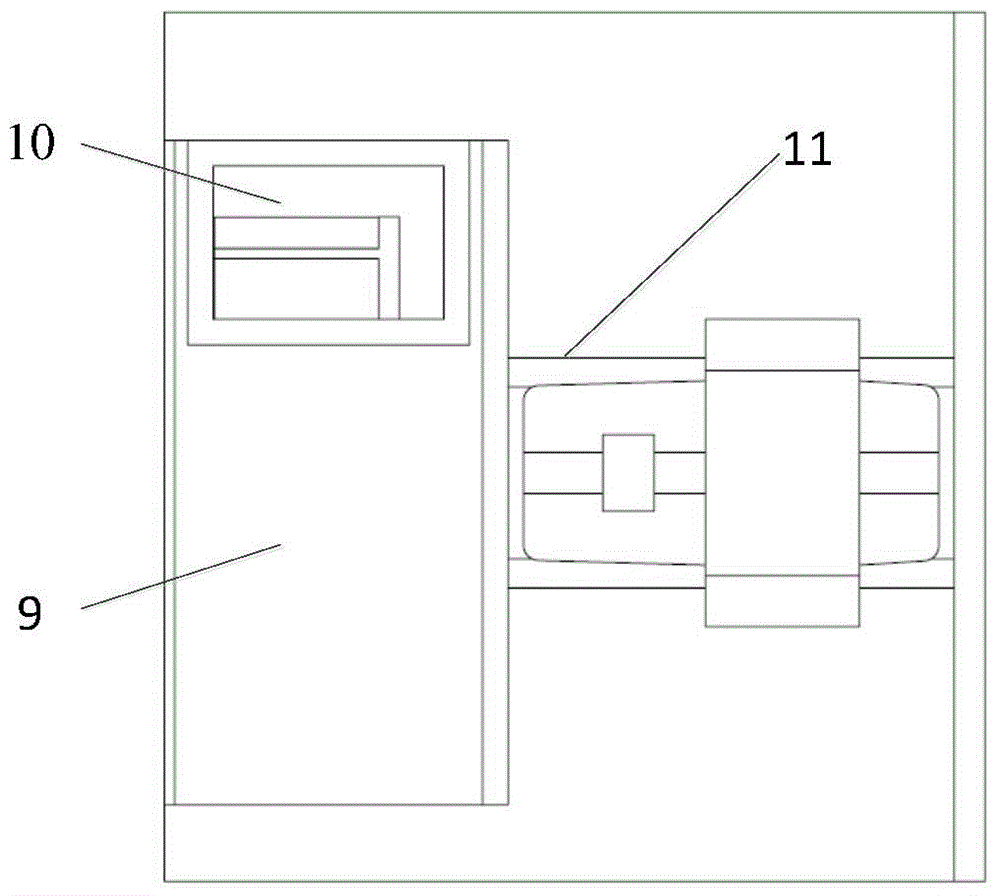

[0030] like figure 2 As shown, the air supply device 1 includes a bellows 9, an impeller 10 and a drive motor 11, the impeller 10 is installed on the shaft of the drive motor 11, the drive motor 11 is installed between the bellows 9 and the side support plate 6 by bolts, and the bellows 9 is welded , vertically fixed on the bottom support plate 5. The impeller 10 is driven by a drive motor 11, providing a stable and suitable airflow source for the cold pyrotechnic eruption device. The bellows 9 plays the role of storing and buffering the air flow. The airflow generated by the rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com