Programmable spinning machine motion simulation test platform

A motion simulation and test platform technology, applied in the field of simulation experiment platform, can solve the problems of high yarn dust density, decreased yarn output, and poor quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

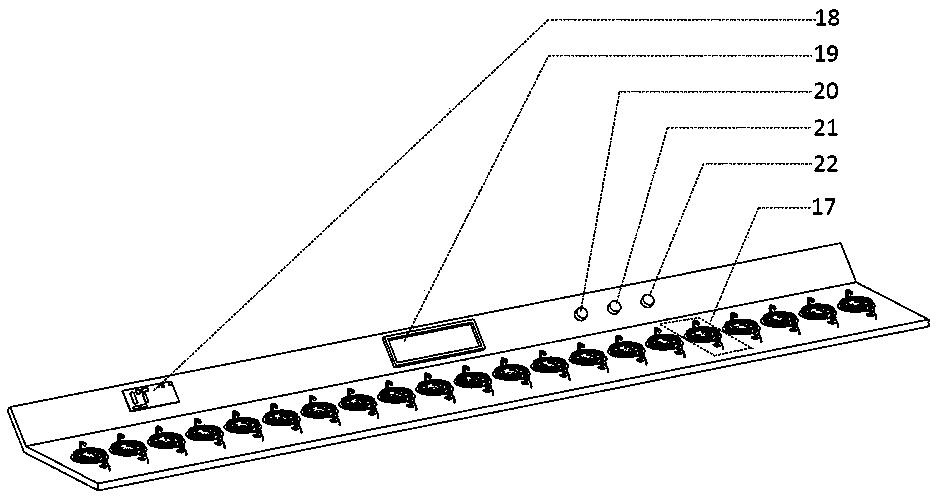

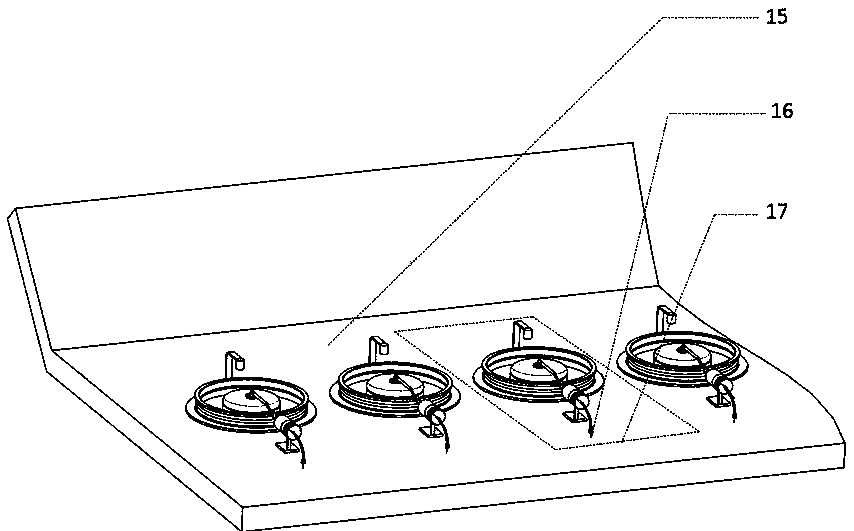

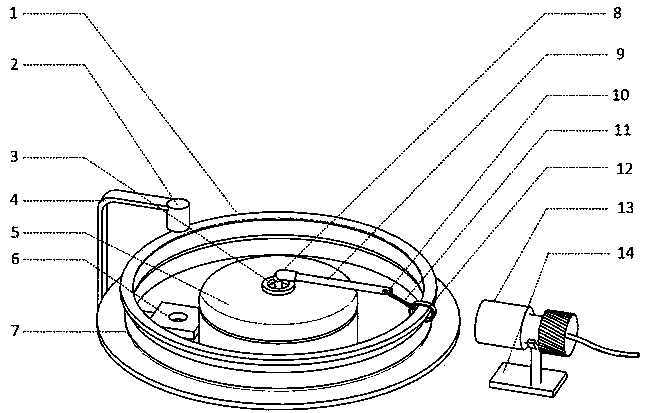

[0031] The present invention is described in detail below with reference to the actual use case and the accompanying drawings. In this example, a self-designed sensor for disconnection detection and rotational speed measurement based on eddy current effect is used as the tested sensor for testing. The measured sensor 13 is installed and fixed on the metal bracket 14 near the outer edge of the ring rail 1. The probe center of the measured sensor 13 and the ring rail 1 are located at a position 6 mm away from the edge of the ring rail 1 in the same horizontal plane. If the position of the measured sensor 13 needs to be changed, the distance between the metal bracket 14 and the steel ring 7 can be adjusted within a certain range. The operation of the spinning frame can be tracked and detected by detecting the movement state of the traveler 12 on the ring track 1, so as to realize the alarm of the spinning frame disconnection and the accurate measurement and monitoring of the spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com