Electrochromic device based on zno nanotubes and its preparation method

An electrochromic device and nanotube technology, which is applied in instruments, nonlinear optics, optics, etc., can solve the problems of easy leakage of devices, low contrast and poor stability of electrochromic devices, and achieve uniform coverage, The effect of improving electrolyte leakage and increasing electron transport speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

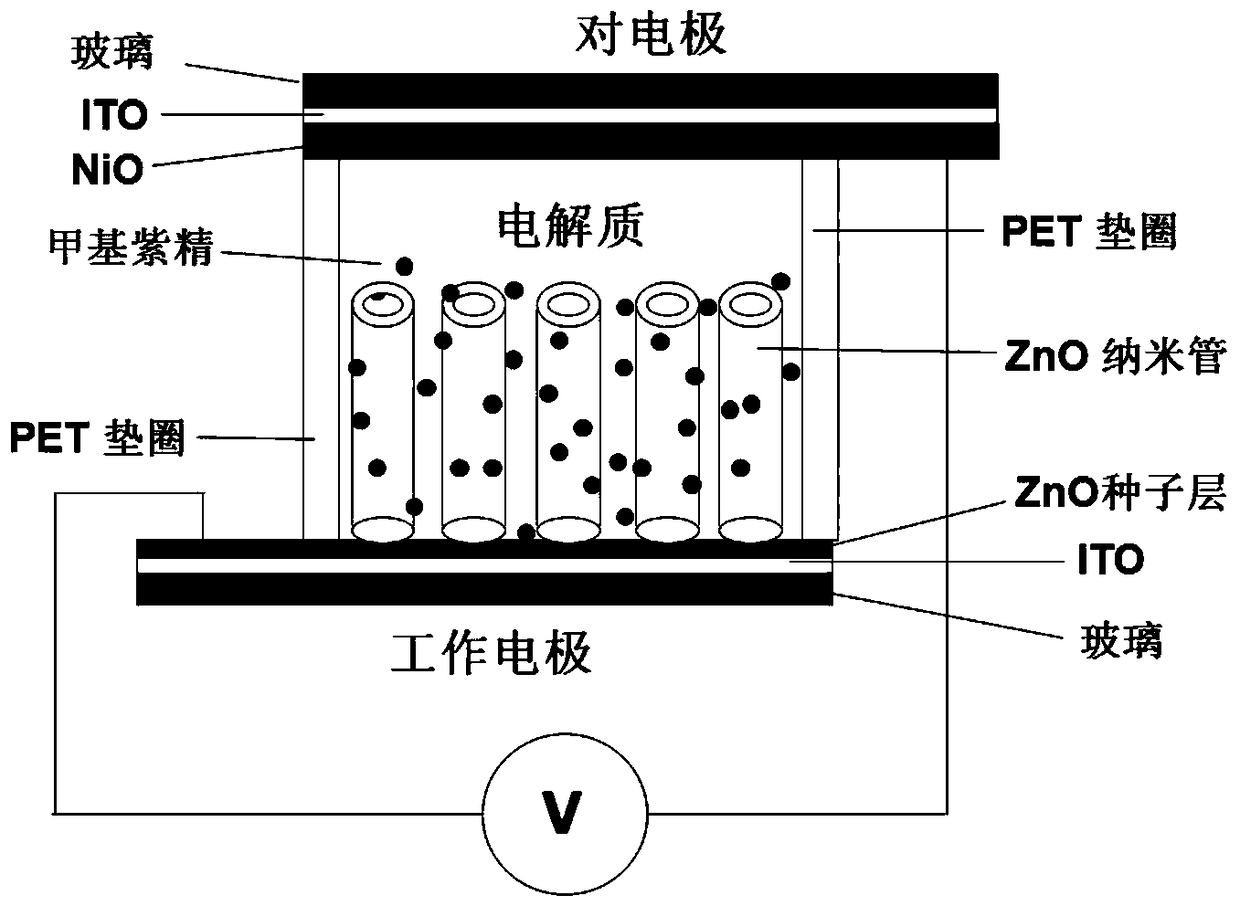

[0031] An electrochromic device based on ZnO nanotubes, including a working electrode, a counter electrode and an electrolyte, wherein the working electrode is ITO glass, its surface is covered with a ZnO nanotube array modified by methyl viologen, and the counter electrode is pure ITO glass , the electrolyte is LiClO 4 γ-butyrolactone solution with a concentration of 0.2M.

[0032] The method for preparing an electrochromic device based on ZnO nanotubes includes preparation of a working electrode, preparation of a counter electrode, preparation of an electrolyte, and packaging of an electrochromic device.

[0033] Wherein, the preparation method of working electrode comprises the following steps:

[0034] Put ITO glass (2.8×2cm 2 ) into isopropanol, acetone, absolute ethanol, and deionized water for ultrasonication in turn, each process takes 15 minutes, and after washing, blow dry with a hair dryer and set aside;

[0035] Step 1, the preparation of the ZnO seed layer, tak...

Embodiment 2

[0044] An electrochromic device based on ZnO nanotubes, including a working electrode, a counter electrode and an electrolyte, wherein the working electrode is ITO glass, the surface of which is covered with a ZnO nanotube array modified by methyl viologen, and the counter electrode is a surface covered with ITO glass with NiO film, electrolyte is LiClO 4 γ-butyrolactone solution at a concentration of 0.2M.

[0045] The method for preparing an electrochromic device based on ZnO nanotubes includes preparation of a working electrode, preparation of a counter electrode, preparation of an electrolyte, and packaging of an electrochromic device.

[0046] Wherein, the preparation method of working electrode comprises the following steps:

[0047] Put ITO glass (2.8×2cm 2 ) into isopropanol, acetone, absolute ethanol, and deionized water for ultrasonication in turn, each process takes 15 minutes, and after washing, blow dry with a hair dryer and set aside;

[0048] Step 1, the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com