Electroslag welding repairing method for anode steel stud head

A technology of anode steel claws and repair methods, which is applied in the direction of welding/welding/cutting items, manufacturing tools, metal processing equipment, etc., can solve the problems of potential safety hazards, large footprint of welding equipment, large one-time investment, etc., and achieve welding High efficiency, high repair efficiency, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below through specific examples.

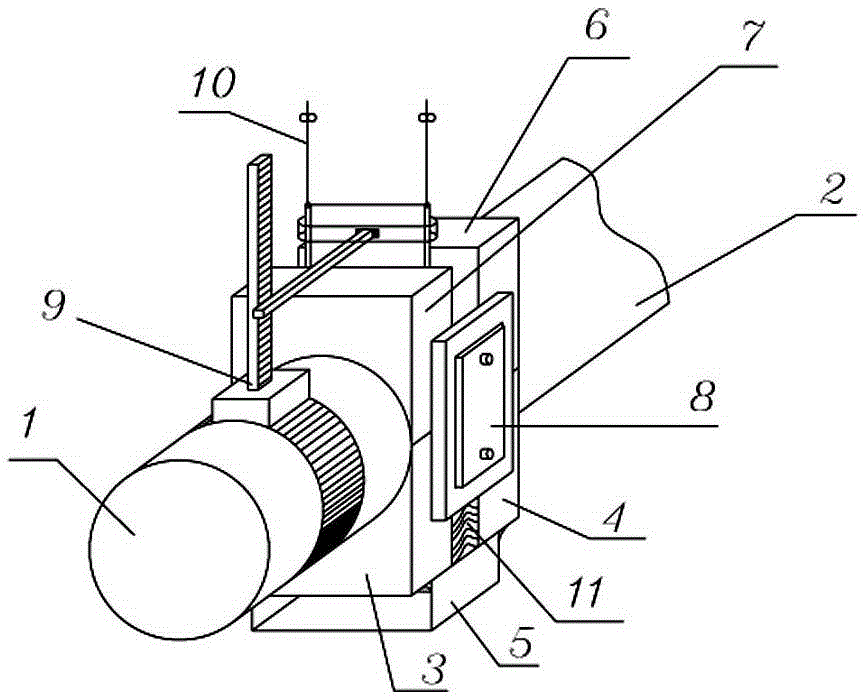

[0027] Aiming at the welding repair of the single-row four-claw head of an electrolytic aluminum factory in China, the material of the steel claw head is ZG230-450, the design diameter is φ180mm, the design length is 280mm, and the length of the burned section is 140mm.

[0028] The first step, preparation before welding

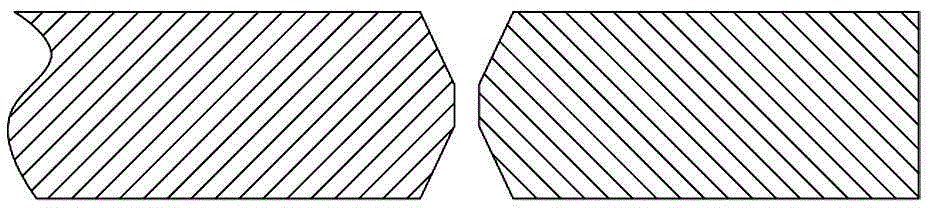

[0029] 1) Use gas cutting to completely remove the burnt section and end of the anode steel claw head 1 to be repaired, leaving 110 mm remaining, select a round steel rod 2 (length 136 mm) of the same material and diameter as the anode steel claw head, and Machining the surface to be welded of the anode steel claw head 1 and the round steel bar 2 to make the surface roughness Ra=6.3~12.5μm;

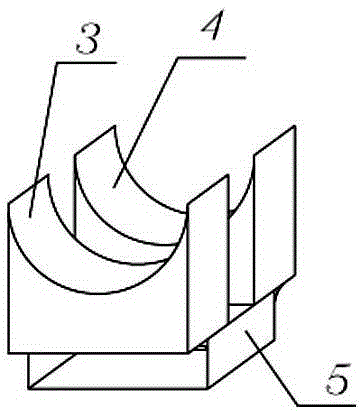

[0030] 2) Processing of welding groove and lead-out plate

[0031] According to the diameter of the anode steel claw head 1, select four cuboid steel plates with a size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com