A terahertz waveguide flange pin precision assembly method and fixture

A wave guide flange and assembly method technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of inability to effectively ensure mutual position accuracy and verticality, low assembly accuracy, etc., to improve production efficiency, economic and social benefits. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following is a further detailed description of a terahertz waveguide flange pin precision assembly method and a fixture of the present invention in conjunction with specific embodiments and with reference to the accompanying drawings.

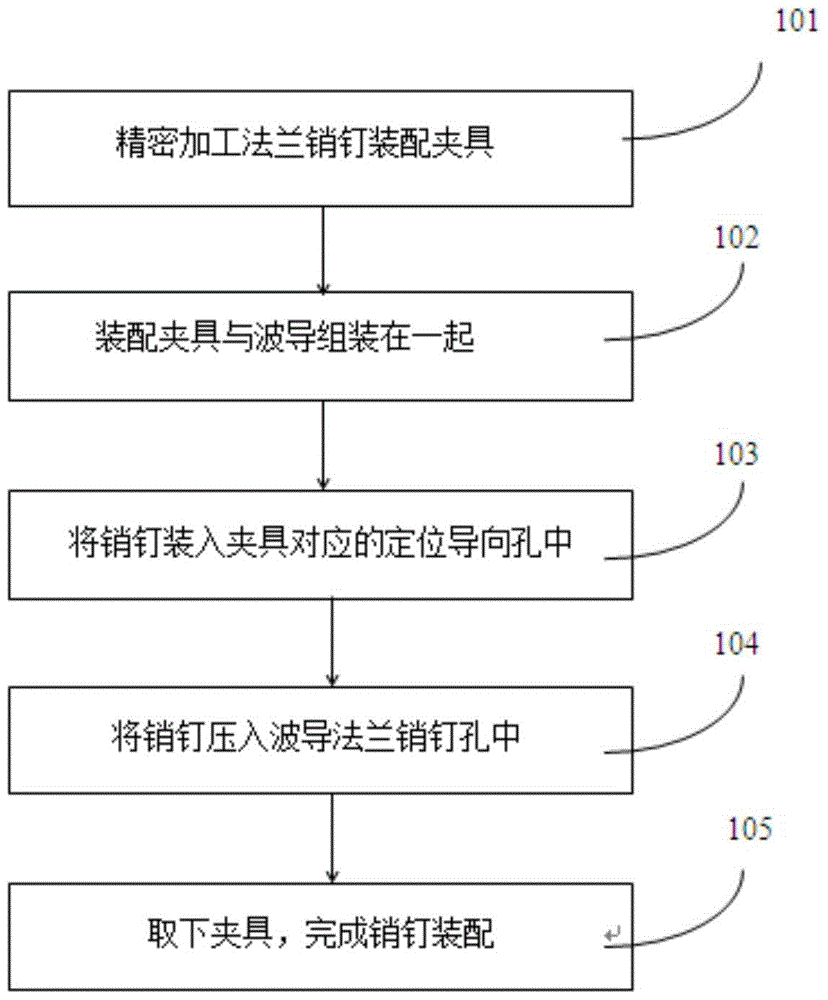

[0037] like figure 1 shown, figure 1 The present invention provides a terahertz waveguide flange pin precision assembly method and a flow chart of the fixture for realizing the waveguide flange pin precision assembly. The method includes the following steps:

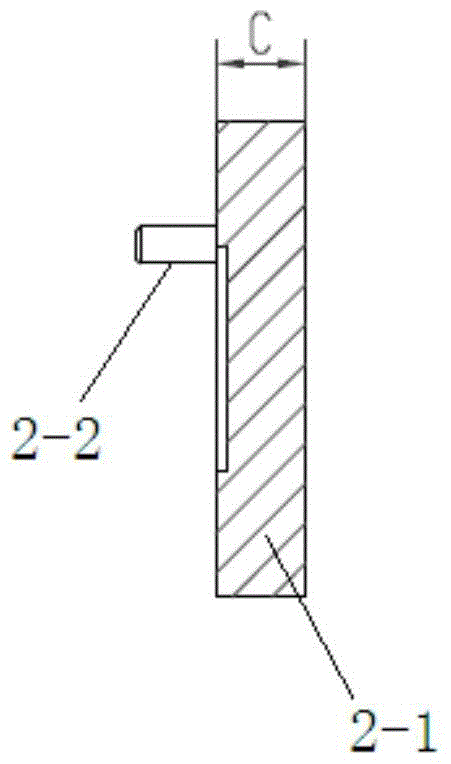

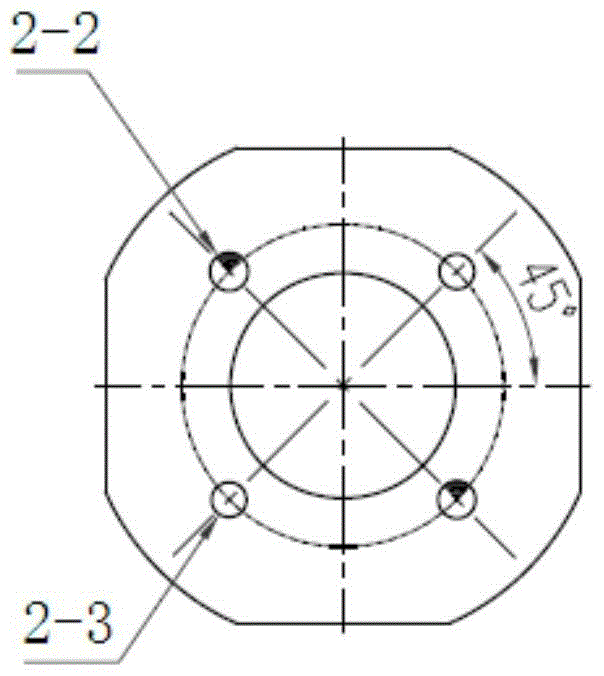

[0038] Step 101: Precisely machine the flange pin assembly jig, and the structural features of the jig are:

[0039] The thickness of the positioning plate 2-1 is C, and there are two guide columns 2-2 on the positioning plate 2-1. The size Φa of the guide columns 2-2 is matched with the size ΦA of the positioning hole 3-2 of the waveguide flange. , the fitting clearance is 0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com