A flexible automatic welding system for communication tower boots

A technology of automatic welding and tower shoe flexibility, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve a high degree of automation, reduce labor, and avoid welding quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

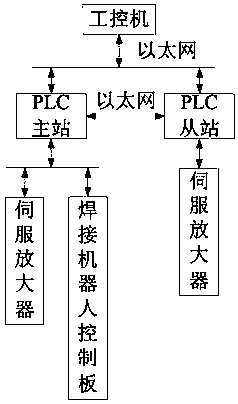

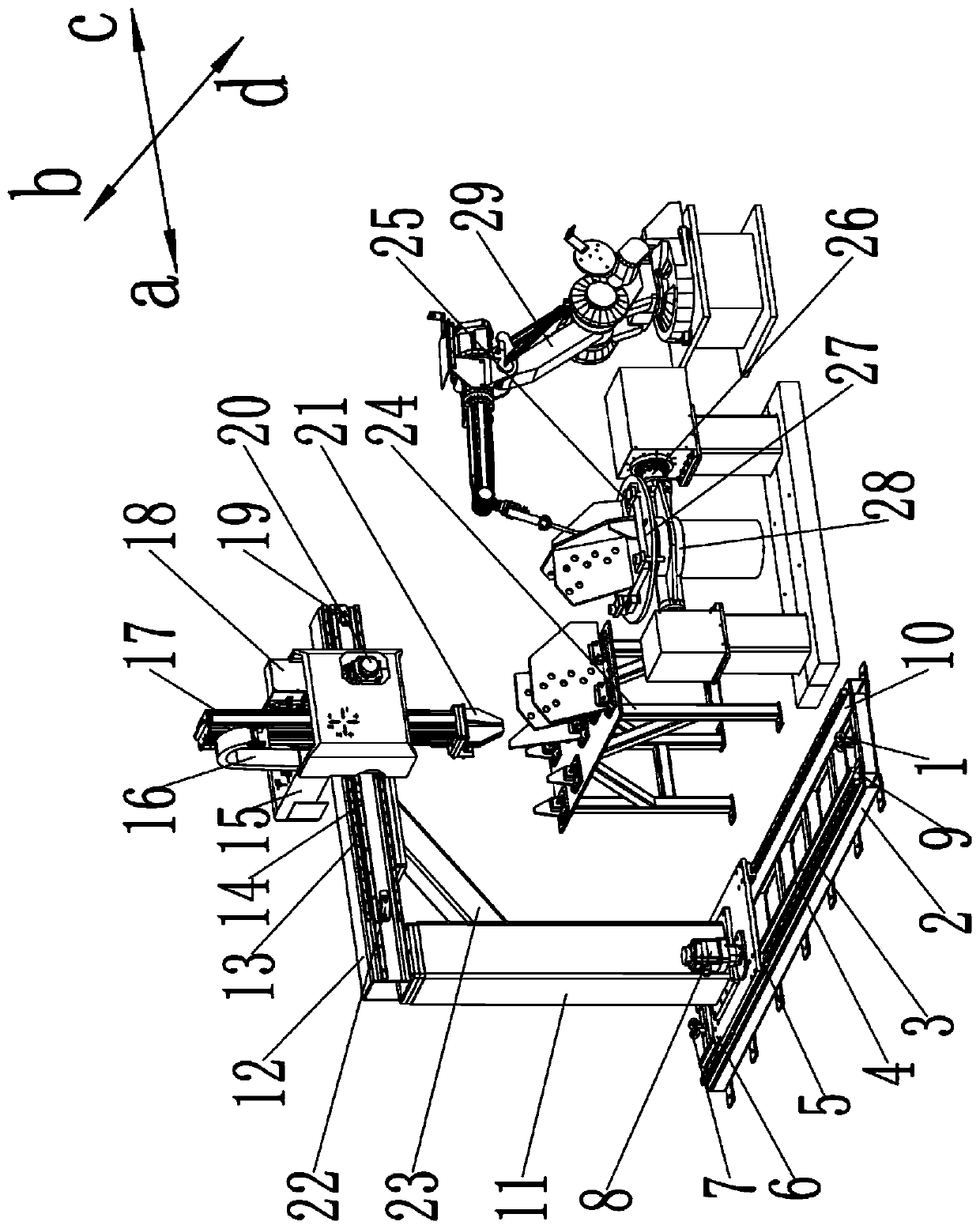

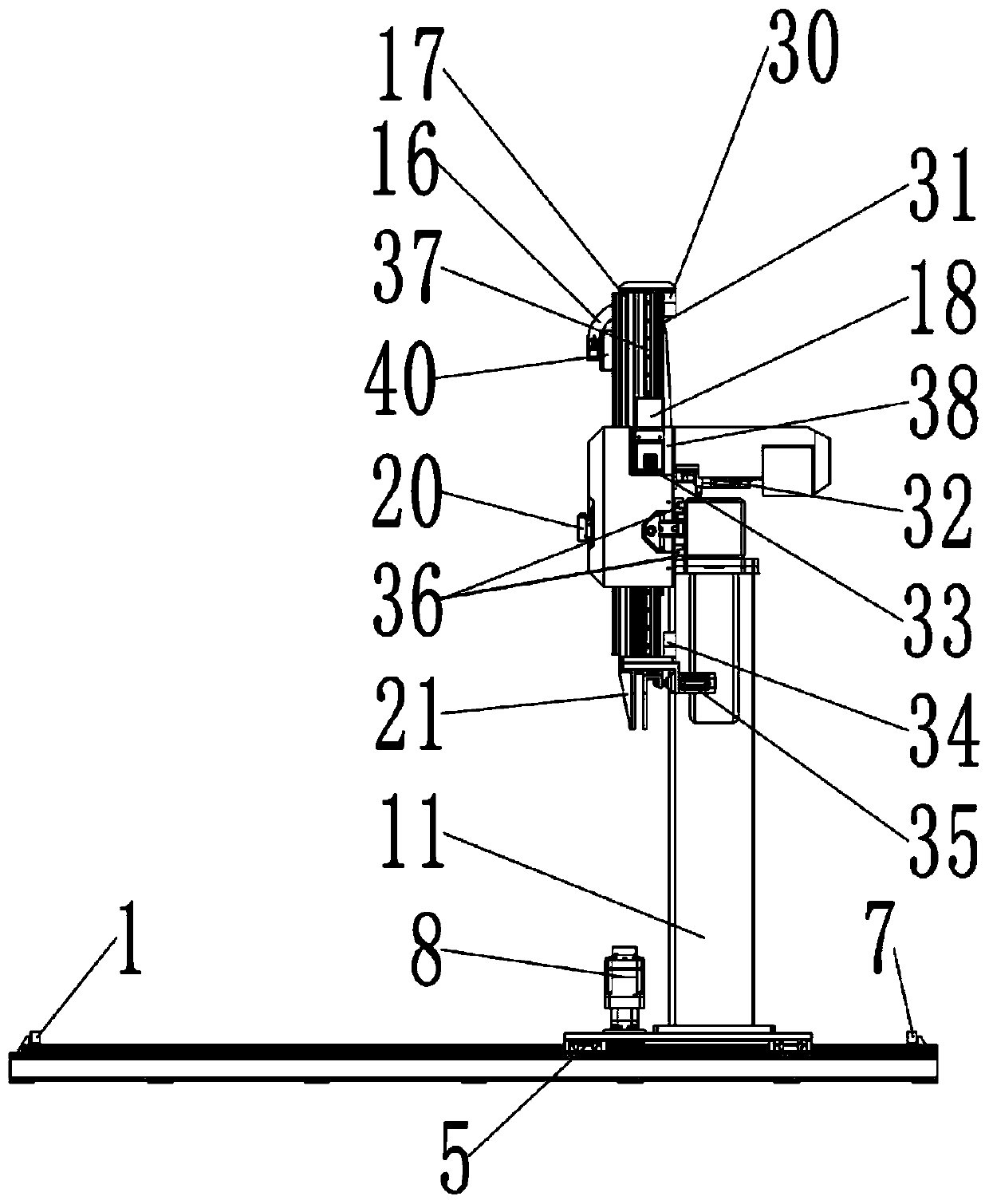

[0030] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] see Figure 1 to Figure 8 .

[0032] Explanation of symbols in the figure:

[0033]The first hard limit stopper 1, the profile base 2, the first track 3, the first rack 4, the first slider 5, the base 6, the second hard limit stopper 7, the first servo motor 8, the first Profile 9, second profile 10, vertical beam 11, beam 12, second rail 13, second rack 14, housing 15, cable drag chain 16, third profile 17, control box 18, third hard limit stopper Block 19, second servo motor 20, gripper 21, fourth hard limit block 22, inclined beam 23, feeding platform (24), bottom bracket 25, turning shaft 26, rotating platform 27, rotating shaft 28, welding Robot 29, the fifth hard limit block 30, the third rack 31, the third servo motor 32, gear 33, the sixth hard limit block 34, cylinder 35, the second slide block 36, the third track 37, Mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com