Quick-dry high-gloss environment-friendly offset printing ink

An offset printing ink, environmental protection technology, applied in the direction of ink, household appliances, applications, etc., can solve the problems of incompatibility with environmental protection requirements, inability to adapt, etc., to achieve excellent gloss, high fixing and drying speed, excellent environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

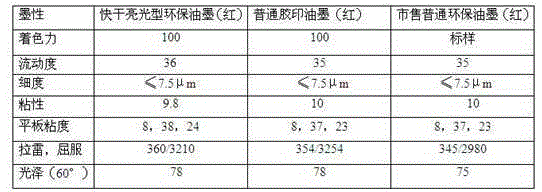

Embodiment 1

[0019] A quick-drying glossy environmentally friendly offset printing ink is prepared from the following components in mass fractions: 60% environmentally friendly binder, 25% pigment and filler, 2.5% alkyd resin, 2.5% vegetable oil, 0.5% dispersant, catalyst Dry agent 1.0%, wax 0.5%, vegetable oil fatty acid ester 8%;

[0020] The environmental-friendly binder is prepared from the following components in mass fractions: 40% rosin-modified phenolic resin, 30% vegetable oil, 28% vegetable oil fatty acid ester and 2% gelling agent.

[0021] The rosin-modified phenolic resin includes a first rosin-modified phenolic resin and a second rosin-modified phenolic resin, and the weight-average molecular weight of the first rosin-modified phenolic resin is 150,000 to 300,000, which is high viscosity, high structure, low Soluble resin, providing body for the ink, and anti-fogging performance, excellent wear resistance, dot definition, printing gloss and ink balance; the weight average mol...

Embodiment 2

[0030] A quick-drying glossy environmentally friendly offset printing ink is prepared from the following components in mass fractions: 55% environmentally friendly binder, 25% pigment and filler, 3% alkyd resin, 3% vegetable oil, 0.5% dispersant, Dry agent 1.5%, wax 2%, vegetable oil fatty acid ester 10%;

[0031] The environmental-friendly binder is prepared from the following components in mass fractions: 35% rosin-modified phenolic resin, 35% vegetable oil, 29% vegetable oil fatty acid ester and 1% gelling agent.

[0032] All the other components are the same as in Example 1.

Embodiment 3

[0034] A quick-drying glossy environmentally friendly offset printing ink, which is prepared from the following components in mass fractions: 65% of environmentally friendly binders, 20% of pigments and fillers, 1% of alkyd resins, 2% of vegetable oils, 1% of dispersants, and Dry agent 1.5%, wax 1.5%, vegetable oil fatty acid ester 8%;

[0035] The environmental-friendly binder is prepared from the following components in mass fractions: 45% rosin-modified phenolic resin, 40% vegetable oil, 14% vegetable oil fatty acid ester and 1% gelling agent.

[0036] All the other components are the same as in Example 1.

[0037] The preparation method of above-mentioned three embodiments, comprises the following steps:

[0038] 1) For ingredients, prepare relevant materials in parts by mass according to the ink formula;

[0039] 2) To prepare an environmentally friendly binder, add vegetable oil and rosin-modified phenolic resin into the reaction kettle, heat up and stir until the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com