A method for making bamboo sheet paper that can be used for writing, drawing and printing of water-based materials

A technology of water-based materials and production methods, applied in special paper, textiles, papermaking, paper and other directions, can solve the problems of running ink, water-based materials easy to smudge ink, easy to mildew and corrosion, etc., to achieve mildew-resistant corrosion, smooth writing , retain the natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

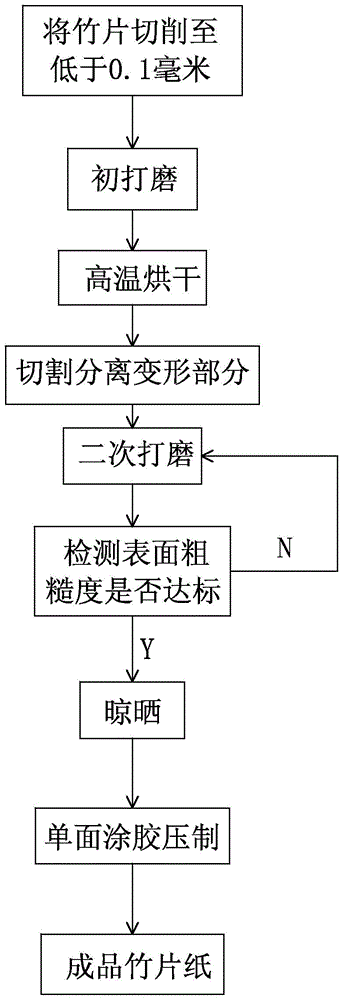

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] combined with figure 1 , a kind of writing and drawing that can be used for water-based material and printing bamboo chip paper production method, it is characterized in that: it comprises the steps:

[0023] The first step is to use a machine to cut the raw bamboo chips to a thickness of less than 0.1mm;

[0024] The second step is to initially polish the cut bamboo chips;

[0025] The third step is to dry the initially polished bamboo chips at high temperature;

[0026] The fourth step is to cut and separate the deformed parts of the dried bamboo chips;

[0027] The fifth step is to perform secondary grinding on the bamboo chips after cutting off the deformed part in the fourth step;

[0028] The sixth step is to check whether the surface roughness of the bamboo chips after the second grinding is up to the standard, if it is up to the standard, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com