Multifunctional tunnel repairing machine

A multi-functional roadway and repairing machine technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problem that repairing equipment cannot be repaired in full section, and achieve the effect of large working surface, flexible and convenient operation, and increased service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

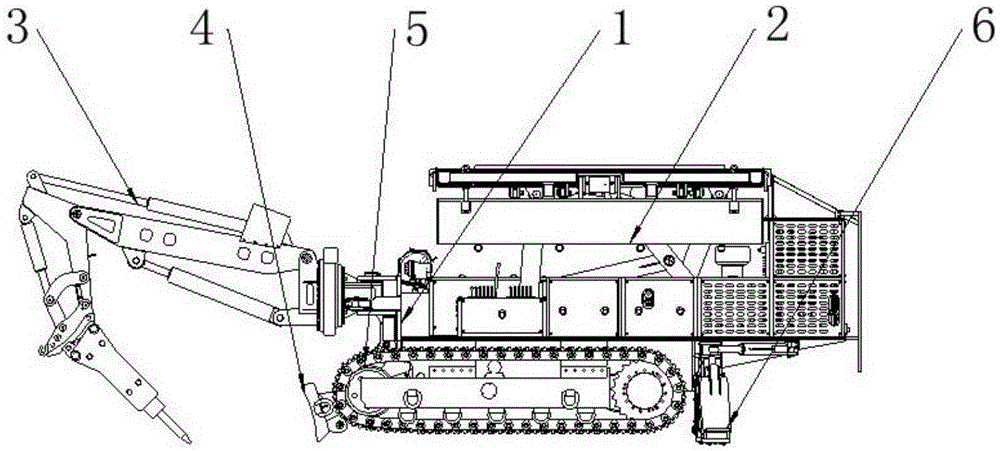

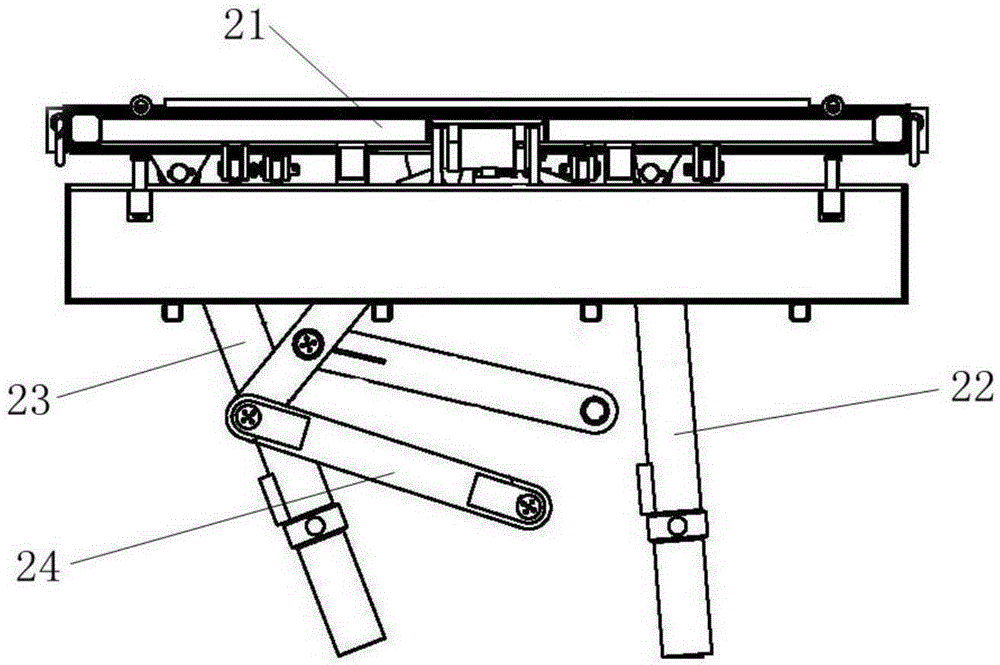

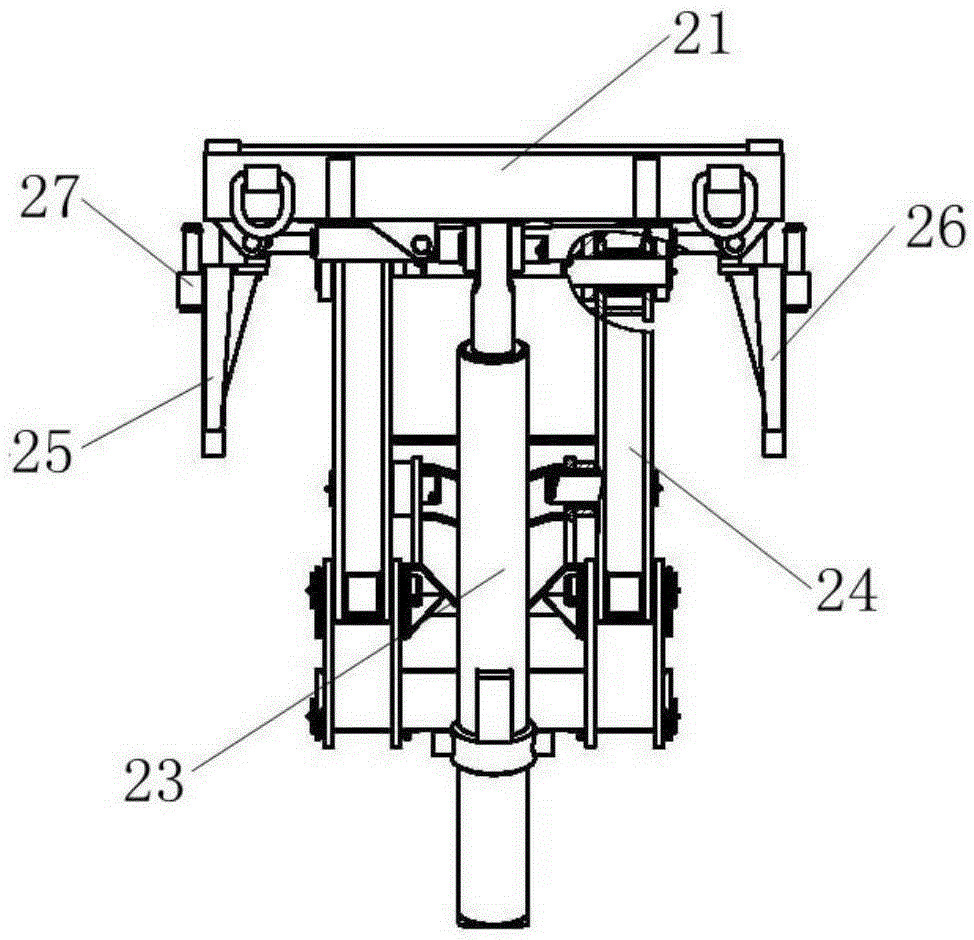

[0024] As shown in the figure, the multifunctional roadway repair machine in this embodiment includes a main frame 1, a working platform 2, a working arm 3, a shovel 4 and a walking track 5; the working platform 2 is arranged above the main frame 1, and the The working arm 3 is hinged in front of the main frame 1 and is driven to swing left and right by a swing cylinder. The shovel plate 4 is hinged at the lower end of the front of the main frame 1 . A hydraulic oil cylinder that moves up and down, and the walking crawler belt 5 is arranged below the main frame 1 and drives the main frame 1 to advance.

[0025] The roadway repair machine completes the repair of the roadway and gangue cleaning through the working arm 3 and the shovel plate 4, and completes the top repair operations such as anchoring and spraying support for the platform in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com