Upper rear drainage-type waterwheel of waterwheel type hydraulic generator

A hydroelectric generator and waterwheel technology, which is applied in the direction of hydroelectric power generation, impact engines, engine components, etc., can solve the problems of increasing the difficulty and cost of waterwheels, so as to improve water energy utilization efficiency, increase flow efficiency, The effect of improving the utilization rate of potential energy and kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

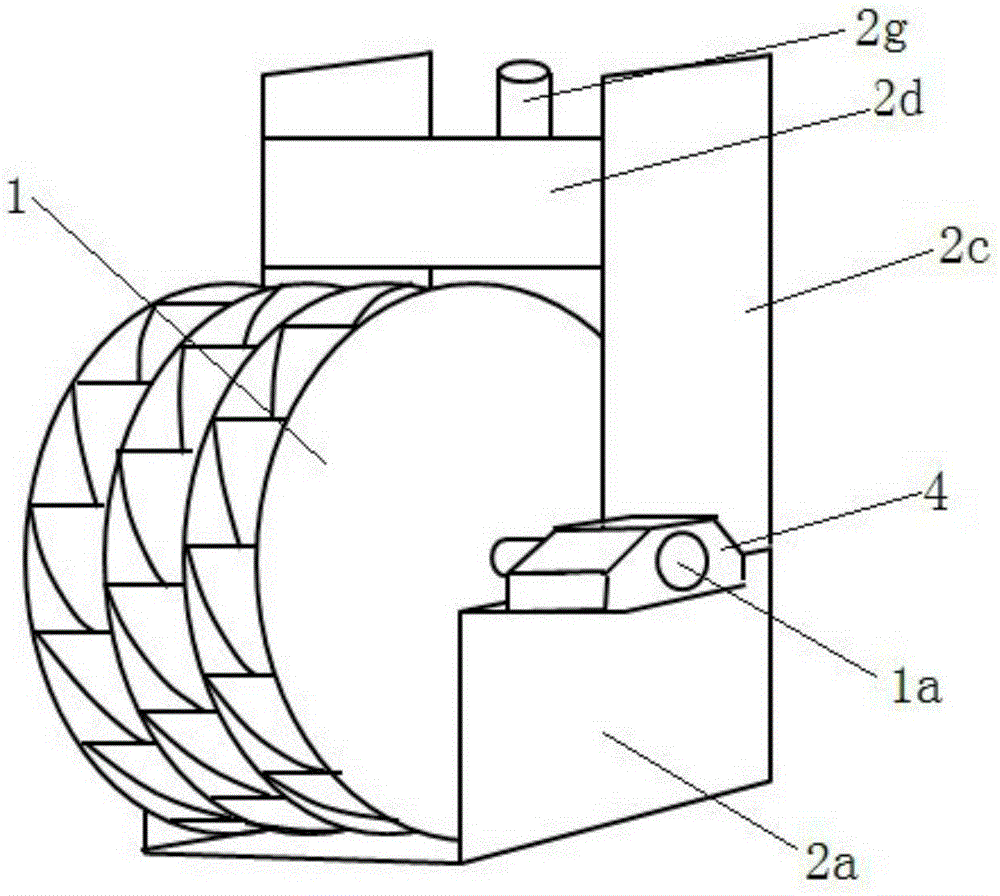

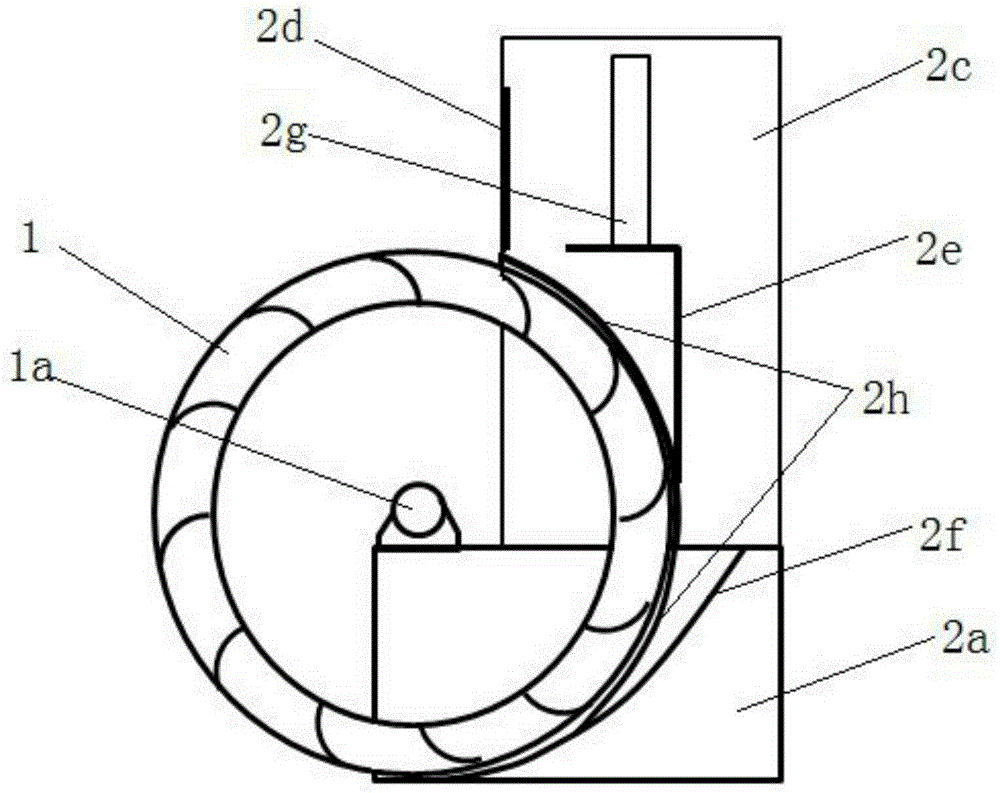

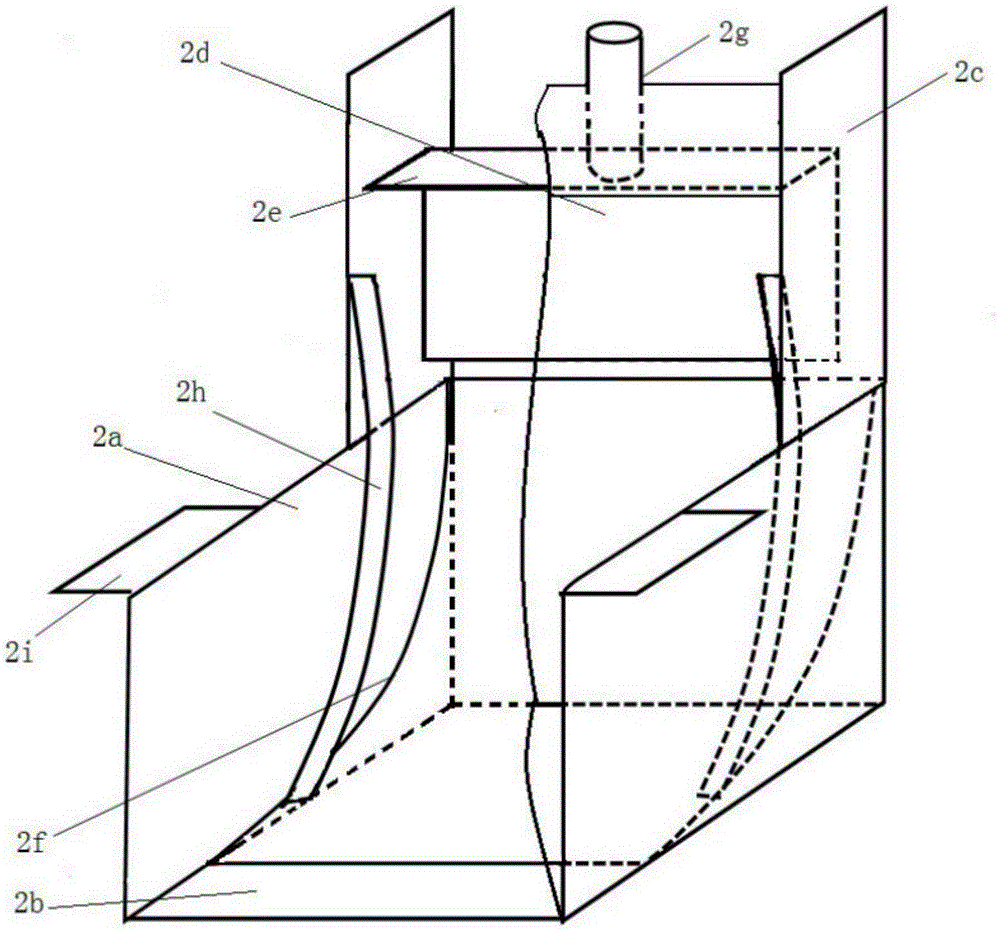

[0014] Such as figure 1 , figure 2 The upper and rear diversion type waterwheel of the shown hydroelectric generator includes a waterwheel 1 that can be driven to rotate along the central rotating shaft 1a by relying on the momentum of water flow, gravity and pressure, and a water guide body that guides the water flow into the bucket of the waterwheel. The water diversion body such as image 3 As shown, it includes a water diversion and diversion tank and a water diversion and diversion box arranged above the water diversion side of the water diversion and diversion tank. The water diversion and diversion tank includes two tank body side baffles 2a, a bottom plate 2b, and a gradually lowering and narrowing rear arc-shaped diversion baffle 2f that guides the water flow to the bucket at the lower part of the waterwheel. . The water diversion and diversion box includes two upper side baffles 2c at the top of the side baffles in the water inlet direction of the tank body and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com