A kind of screw vacuum pump with dynamic sealing structure

A technology of screw vacuum pump and dynamic sealing structure, which is applied in the direction of rotary piston type/oscillating piston type pump parts, sealing device of piston pump, parts of pumping device for elastic fluid, etc., which can solve the problem of fragile sealing components, The service life is reduced, the gas temperature rises and other problems, and the effect of reducing wear and temperature rise, reducing high wear and lowering working temperature is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

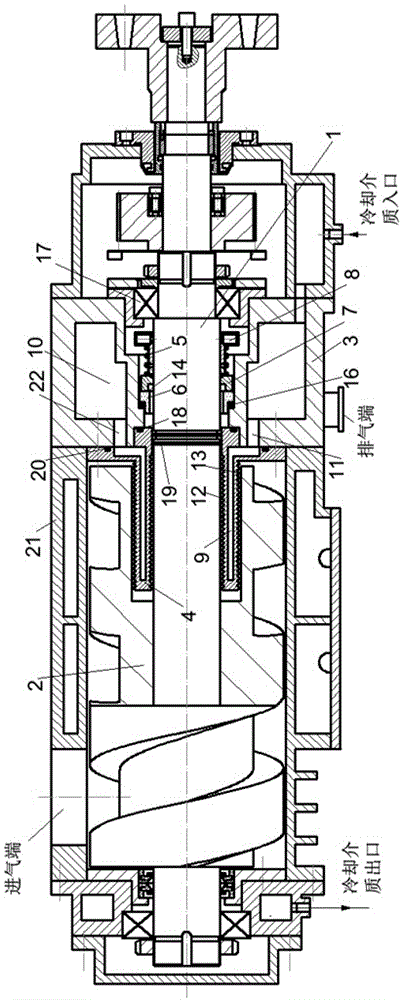

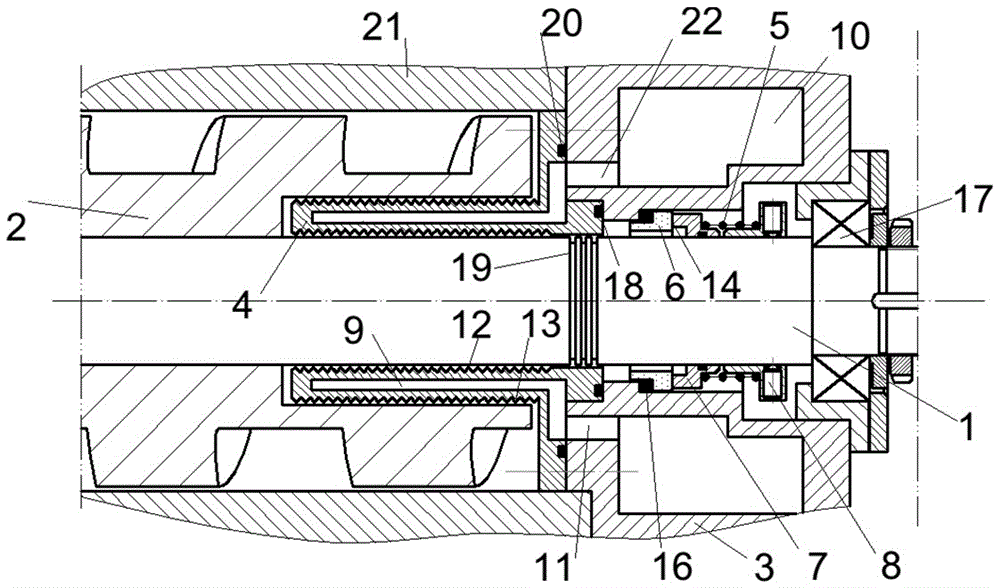

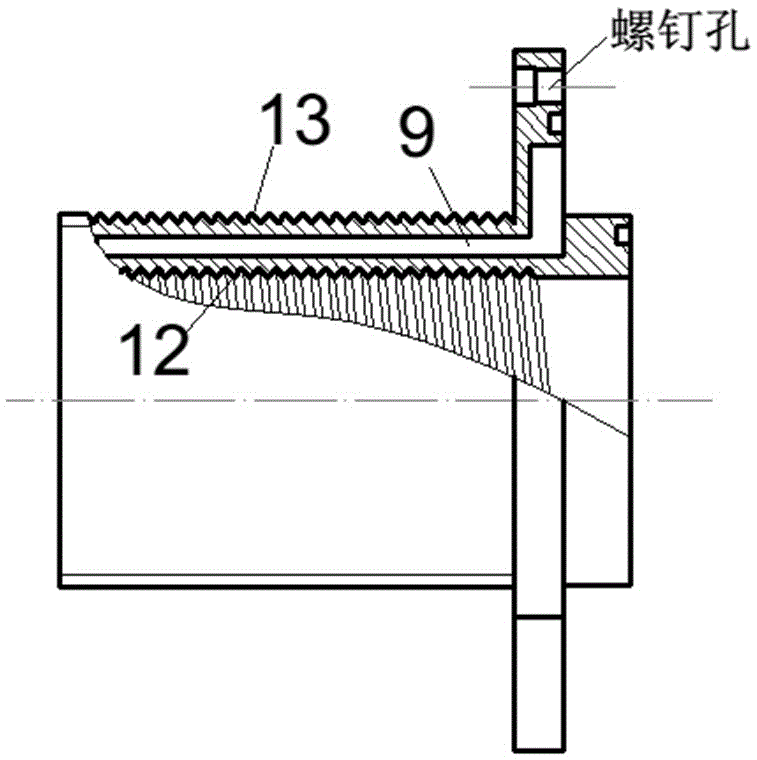

[0038] see figure 1 , a screw vacuum pump with a dynamic seal structure includes a pump body 21, a front end cover 3, a rear end cover, a shaft 1 and a rotor 2. One side of the pump body 21 is radially provided with an air inlet port, and the front end cover 3 and the rear end cover are respectively fixedly mounted on both ends of the pump body 21 in the axial direction. One side of the front end cover 3 is respectively provided with an exhaust port and a cooling medium inlet in the radial direction. A cooling medium outlet is arranged radially on one side of the rear end cover. The rotor 2 is set and fixed on the shaft 1, and the rotor 2 is located in the pump body 21; one end of the shaft 1 is fixed in the rear end cover, and the other end extends to the outside of the front end cover 3, and a sealing mechanism is provided between the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com