Apparatus for achieving in-situ micromechanics, microstructure and component integrated research in scanning electron microscope

A micromechanics, scanning mirror technology, applied in scanning probe technology, instruments, etc., can solve problems such as inability to deepen scientific problems, incompatibility with signal acquisition, inability to perform real-time in-situ measurement and characterization, and achieve compact structure and design. Compact structure and small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

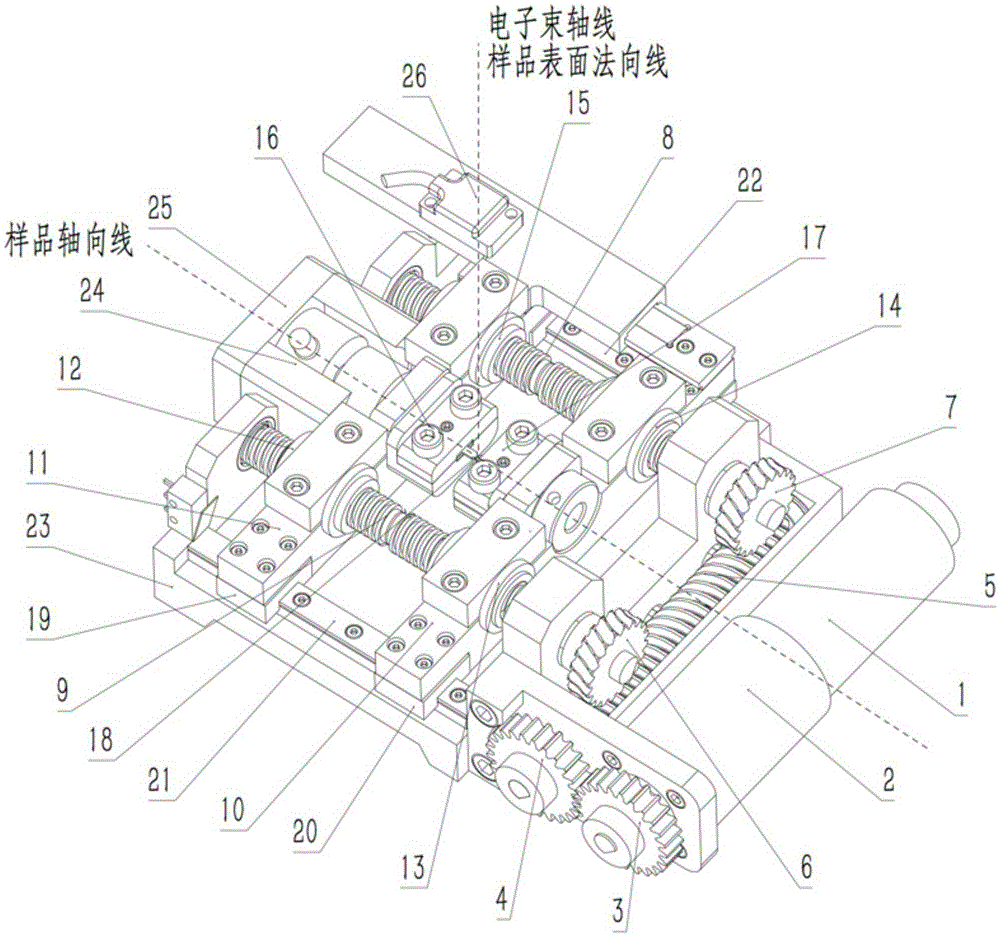

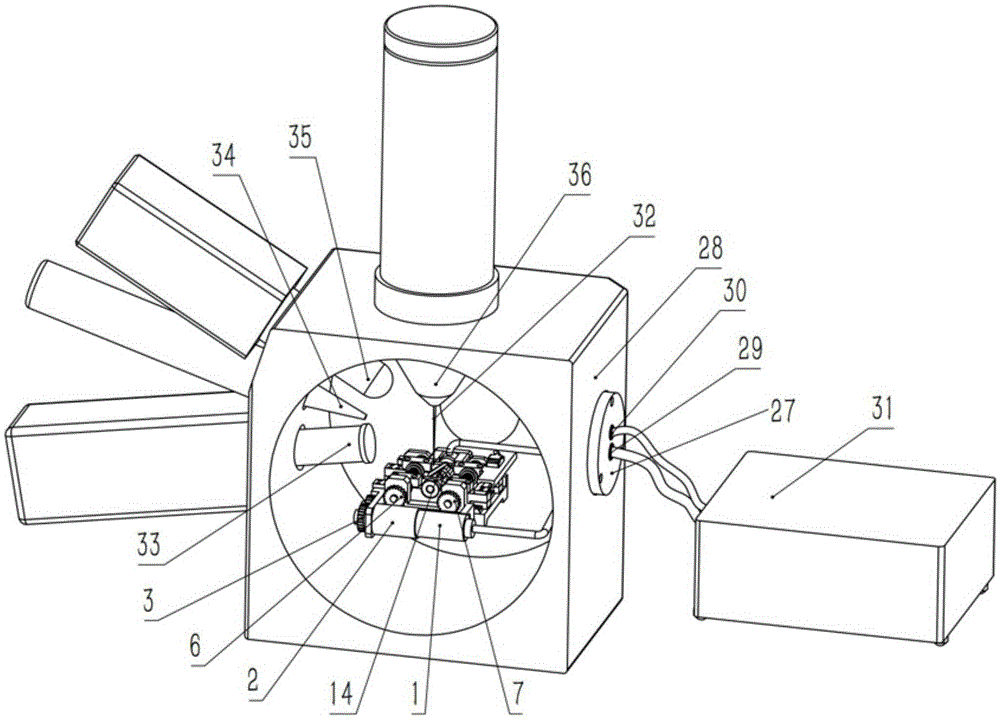

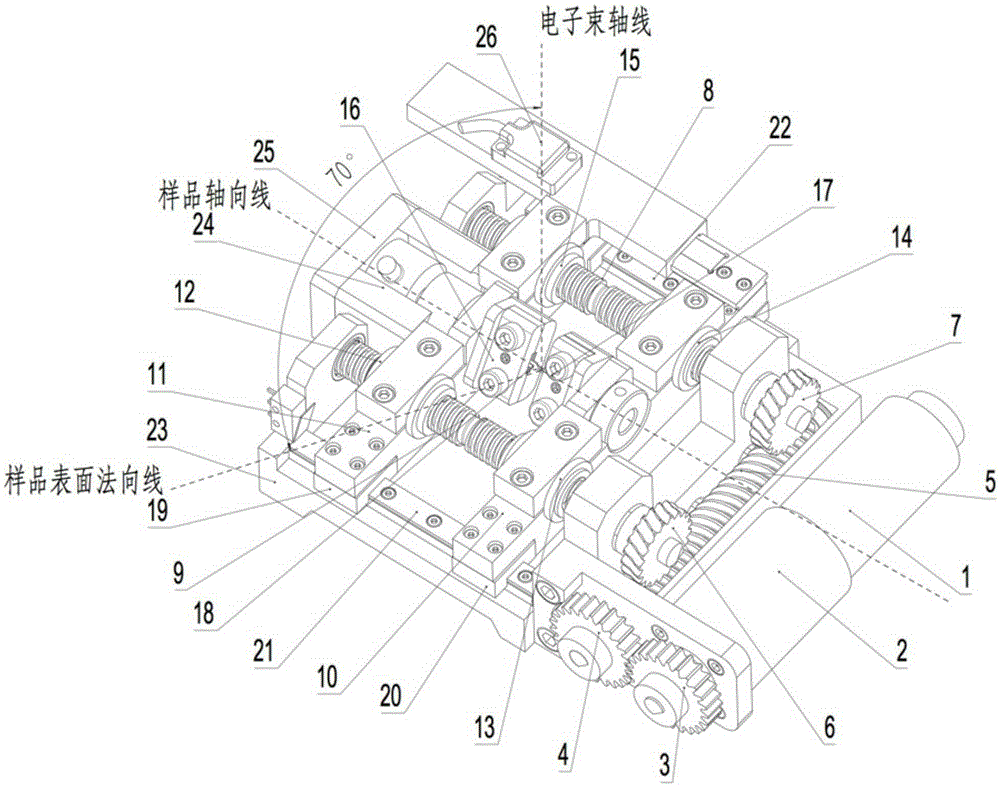

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] A device for in-situ micromechanics, microstructure, and component integration research in a scanning electron microscope is designed based on FEIQuanta650 field emission environmental scanning electron microscope, FEIQuanta250 tungsten filament environmental scanning electron microscope and JEOLJSM6500F field emission scanning electron microscope. The length, width and height of the device are 140mm*110mm*45mm, which can be easily installed in the sample room of the scanning electron microscope. The load range is 0-2000N, the load accuracy is 0.1% FSO, the displacement stroke range is 0-25mm, and the displacement accuracy is 0.02um. The rate range is 0~40um / s. In the experiment, in the FEIQuanta250 tungsten filament environmental scanning electron microscope, the microscopic deformation process and the microscopic crack propagation proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com