Air-tight fiber wall-penetrating socket

An air-tight, optical fiber technology, applied in optics, light guides, optical components, etc., can solve the problems of inability to process, easily damaged optical fibers, low qualification rate, etc., and achieves easy processing and assembly, large number of channels, and good air tightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

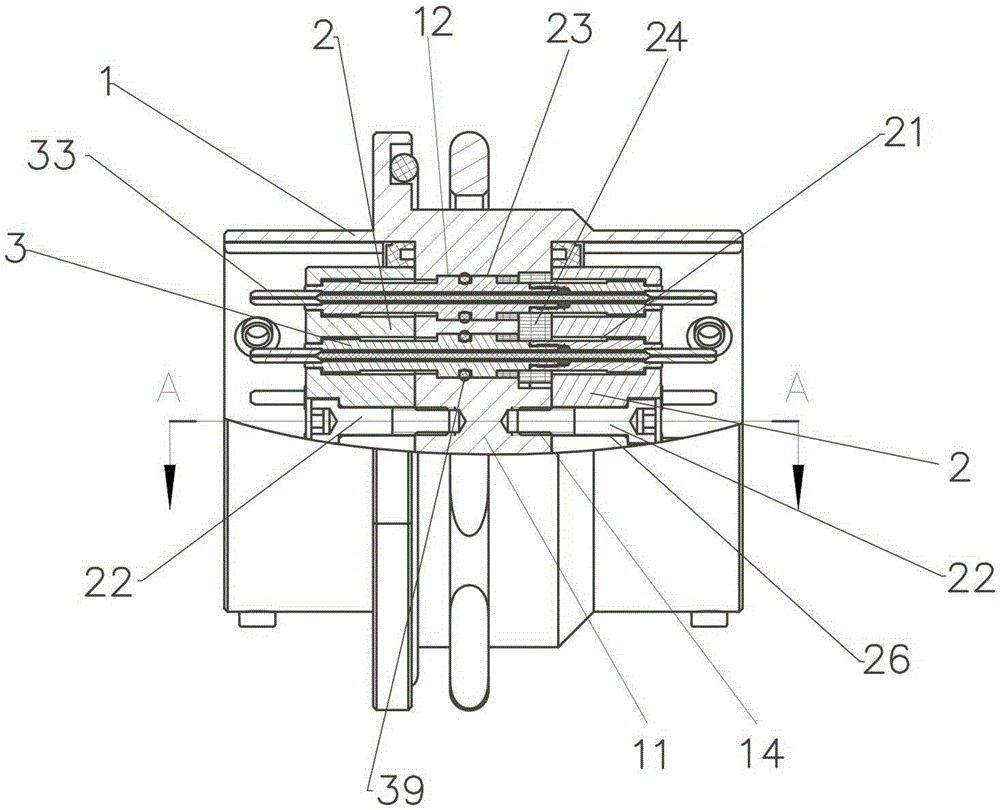

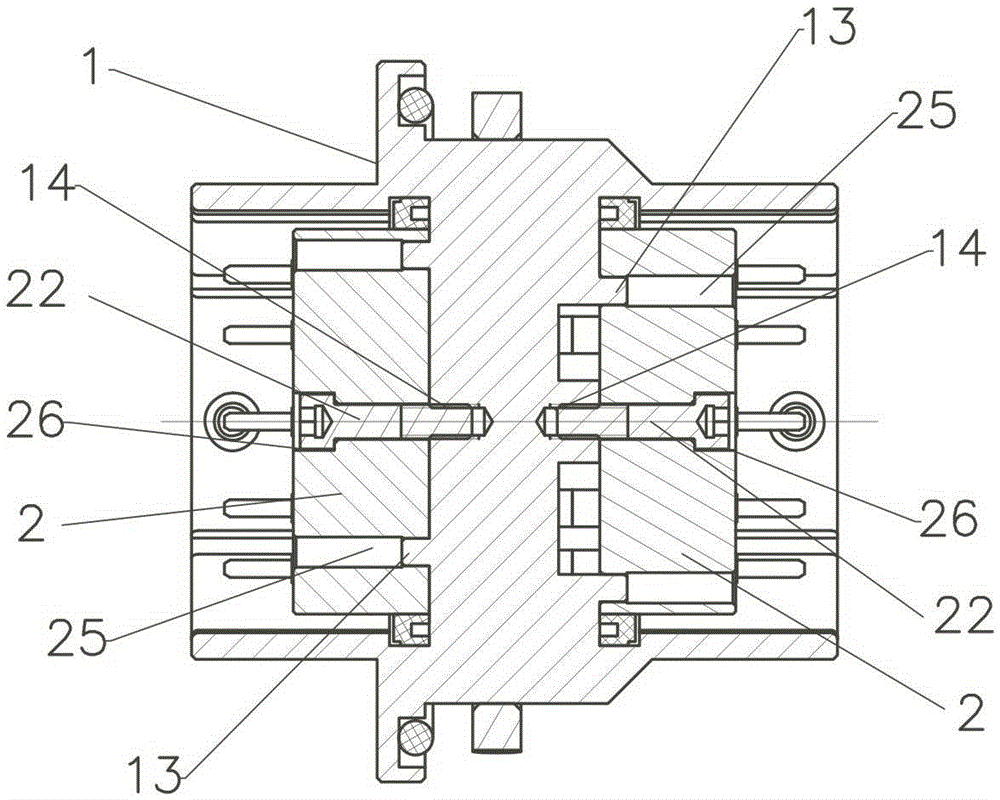

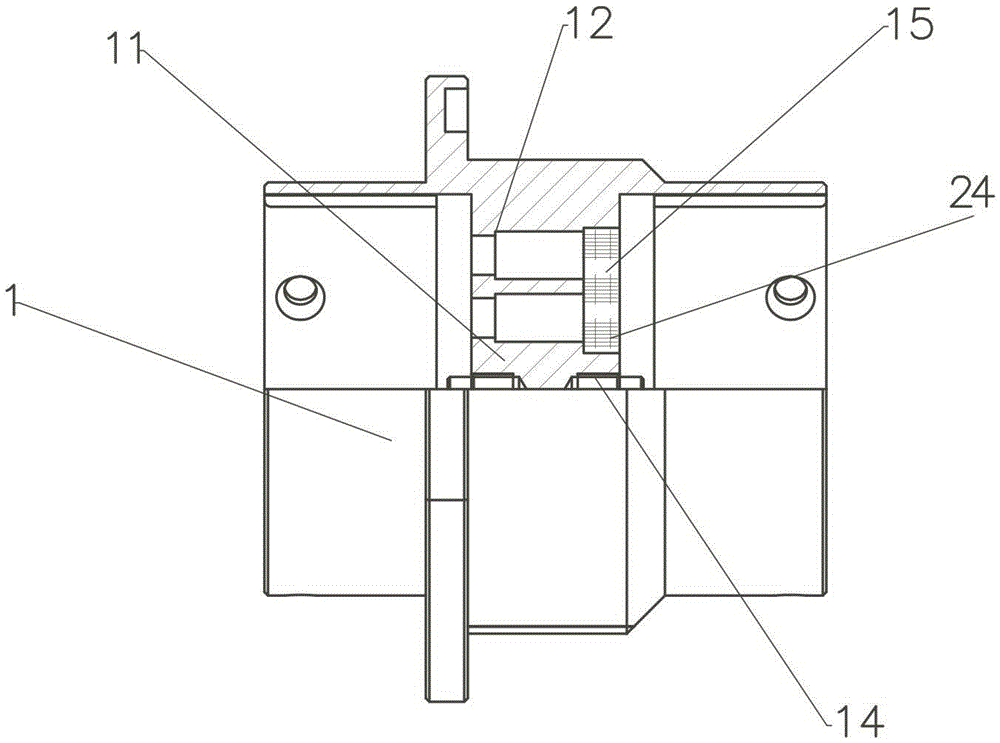

[0015] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention includes:

[0016] A cylindrical housing 1 with a partition wall 11 in the middle, several pin limit holes 12 are provided on the partition wall 11, a silicone groove 15 is provided on one end of the partition wall 11, and positioning bosses 13 and screw threads are provided on both ends of the partition wall 11. Blind hole 14; a pressure plate 2 provided with a pin step hole 21, a positioning hole 25 and a screw counterbore 26 respectively corresponding to the pin limit hole 12 of the housing 1, the positioning boss 13 and the threaded blind hole 14; There is a ferrule assembly 3 with a front sleeve 31, a rear sleeve 32, a ceramic ferrule 33 and a tightly wrapped optical fiber 36; The hole 35 and the boss 37, the tight-packed optical fiber 36 are located in the tube holes of the front sleeve 31 and the rear sleeve 32, and the ceramic insert pins 33 are two pieces, and are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com