A flexible circuit board production line

A flexible circuit board and production line technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of high scrap rate, low production efficiency, and sheet-like thin plates are easy to jam, so as to reduce the space occupied by equipment, The effect of improving production efficiency and increasing thickness range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-5 Shown is a preferred embodiment of the invention.

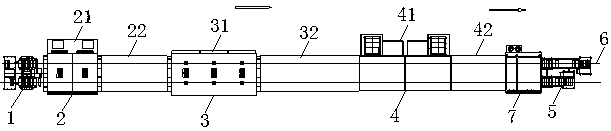

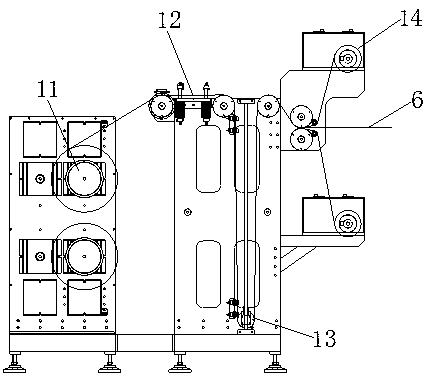

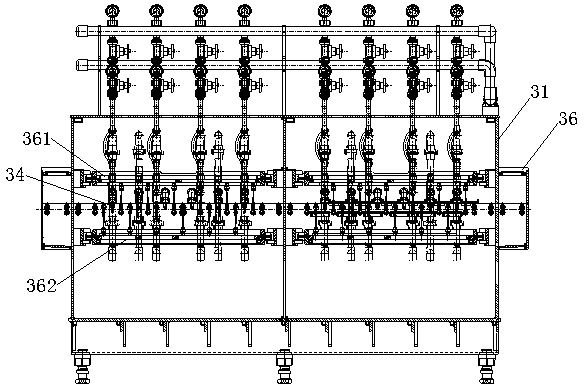

[0032] A flexible circuit board production line, such as figure 1 , including double-row unwinder 1, double-row developing section 2, double-row vacuum etching section 3, double-row unfilming section 4 and double-row winder 5, and double-row unwinder 1 cooperates with double-row winder 5 Used for unwinding and rewinding of the flexible circuit board 6, the double-column developing section 2 includes a developing machine 21, behind the developing machine 21 is provided with a post-development washing section 22, and the double-column developing section 2 is used for the flexible circuit board 6 The cover film of the non-circuit area on the surface is removed to expose the circuit and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com