Flue gas purifying and stabilizing device of flat glass melting furnace

A flue gas purification, flat glass technology, applied in chemical instruments and methods, dispersed particle separation, separation methods and other directions, can solve the problems of large denitration catalyst scouring, affecting dust removal efficiency, difficult control of waste heat boilers, etc. The effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

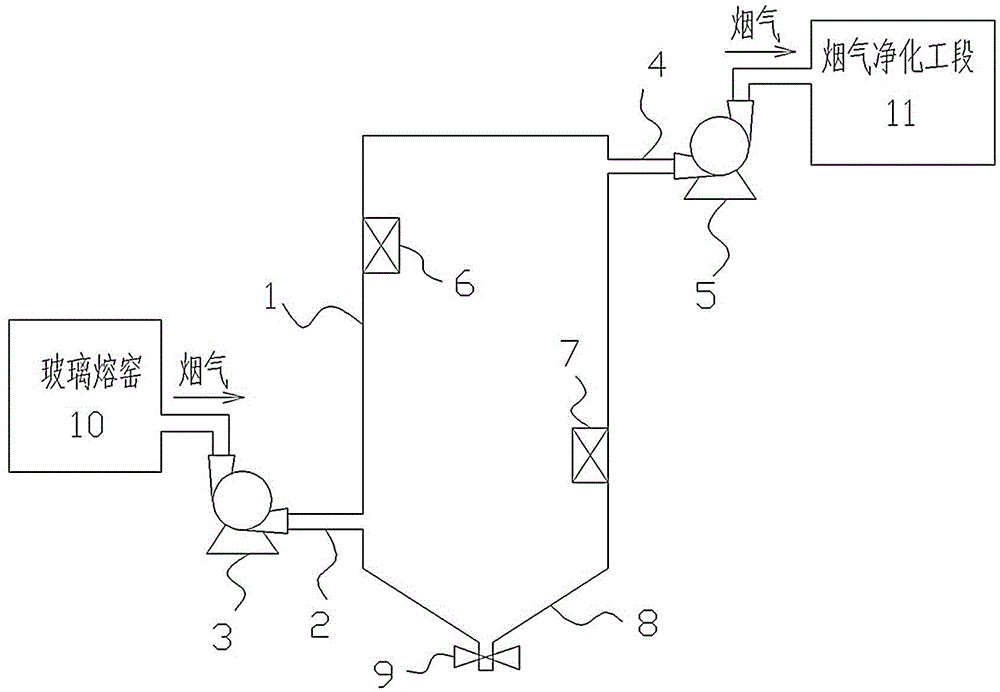

[0010] Such as figure 1 As shown, the present invention provides a flue gas purification and stabilizing device for a flat glass melting furnace, which includes a gas bin 1 whose volume is the volume of flue gas produced in one fire change cycle of the glass melting furnace; the gas bin 1 passes through the smoke inlet pipe 2 It is connected with the smoke outlet of the glass melting furnace 10, and the gas chamber 1 is connected with the flue gas purification section 11 through the smoke outlet pipe 4; The smoke outlet fan 5 is provided on the pipeline; the inner wall of the gas chamber 1 is provided with a first circulation fan 6 and a second circulation fan 7, and the first circulation fan 6 and the second circulation fan 7 are arranged alternately on the upper part of the inner wall of the gas chamber 1 And the lower part; the bottom of the gas chamber 1 is also provided with an ash hopper 8, and the bottom of the ash hopper 8 is provided with a valve 9.

[0011] Before t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com