Melting-type ultrasonic vibration device of continuous casting crystallizer

A continuous casting mold and vibration device technology, applied in the field of metallurgical continuous casting engineering, can solve problems such as unsustainable production and melting of ultrasonic vibration transmission rods, and achieve the effects of improving solidification structure, reducing superheat and temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings of the embodiments.

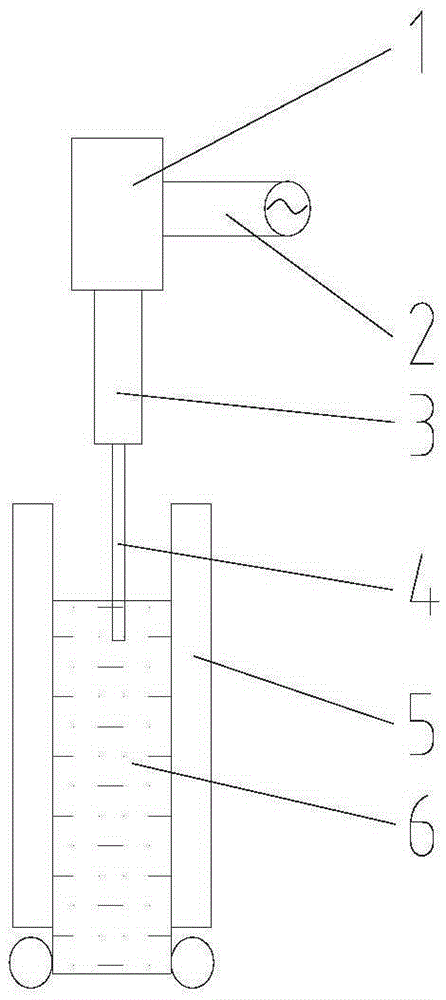

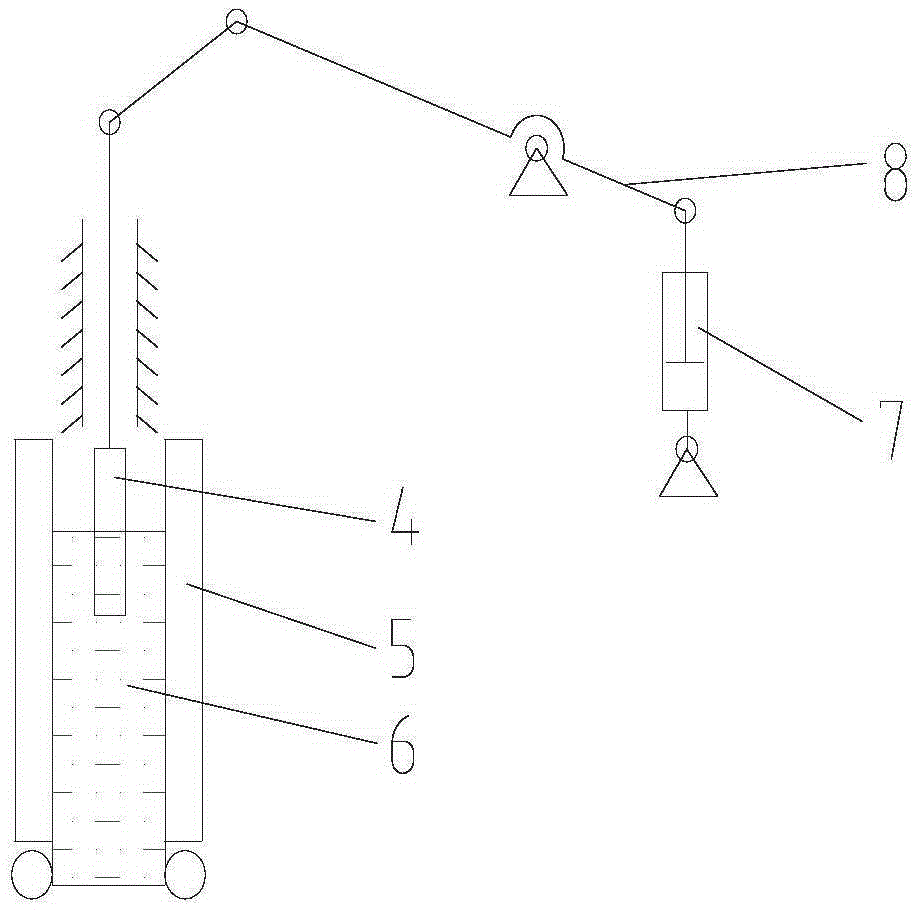

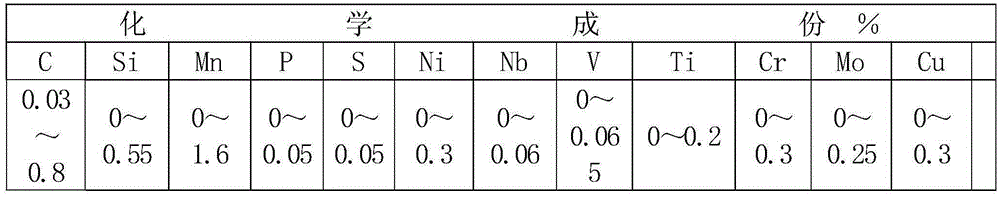

[0021] Such as figure 1 As shown, a continuous casting crystallizer melting type ultrasonic vibration device of the present invention includes an ultrasonic transducer 1, an ultrasonic generator 2 connected to the side of the ultrasonic transducer 1, and a horn connected to the lower end of the ultrasonic transducer 1 3. The lower end of the horn 3 is an ultrasonic vibration transmission rod 4 inserted into the molten steel 6 of the crystallizer 5, and the ultrasonic vibration transmission rod 4 is made of a cast steel material similar to the cast steel type and with added trace alloy elements. The trace chemical components and their weight percentages in the manufactured ultrasonic vibrating rod 4 are as described in Table 1: the ultrasonic vibrating rod 4 is allowed to melt into the molten steel 6 during the pouring process.

[0022] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com