An automatic production line for sawing aluminum alloy profiles

An automatic production line, aluminum alloy profile technology, applied in metal sawing equipment, sawing machine devices, metal processing and other directions, can solve the problems of low production efficiency, unsatisfactory production equipment accuracy, etc., to improve production efficiency, widen the range of processing angles, Set the effect of the exact location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

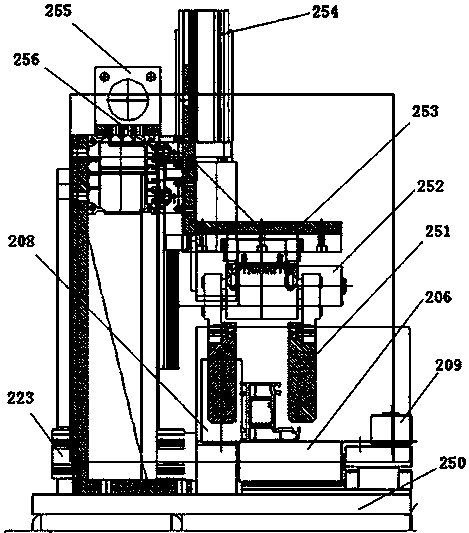

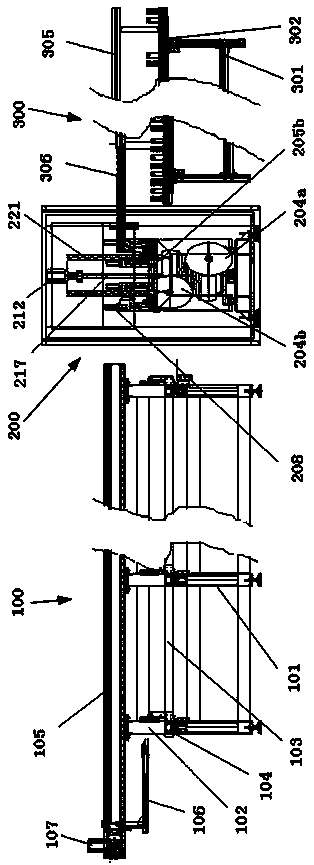

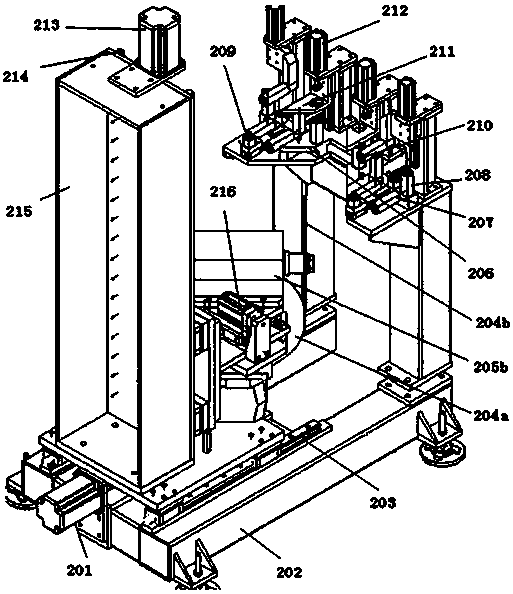

[0014] Refer to the following Figure 1-Figure 7 , the technical solution of the present invention will be described in detail. In the present invention, refer to figure 1 , Profiles are conveyed and processed from left to right on the production line, the left and right directions are taken as the X-axis direction, the front-to-back direction is taken as the Y-axis direction, and the vertical direction is taken as the Z-axis direction of the production line. One side of the discharge table is used as the front of the equipment.

[0015] The technical solution of the present invention is an automatic production line for sawing aluminum alloy profiles, figure 1 It is a schematic diagram of the front structure of the sawing automatic production line. The production line includes a frame, and the frame includes the feeding table frame 101 in the feeding device 100, the transfer mechanism frame 102, and the discharging table frame 301 in the discharging device 300. And the rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com