Preparation method of powder type graphene oxide

A graphene and powder technology, applied in the field of powdered graphene oxide preparation, can solve the problems of large space occupation, long time consumption, unfavorable environmental protection, etc., and achieve the effects of convenient storage, shortened experiment time, and convenient quantitative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Weigh 2g graphite powder and 1gNaNO 3 In the round bottom flask, add 46mL of concentrated sulfuric acid, and stir in ice bath for 5min;

[0019] (2) Then slowly add 6gKMnO 4 , the temperature does not exceed 20°C. The ice bath was removed, and the flask was placed at 35±3°C for 2h. At this point, the solution was dark green;

[0020] (3) Slowly add 92mL deionized water, raise the temperature to 98°C, keep it for 15min, then add 280mL warm water, stir for 5min, then add 30mLH 2 o 2 ;

[0021] (4) Add 1+9HCl80mL after cooling. After standing still for 12 hours, pour off the supernatant liquid, wash and centrifuge the lower layer solution to about pH=6,

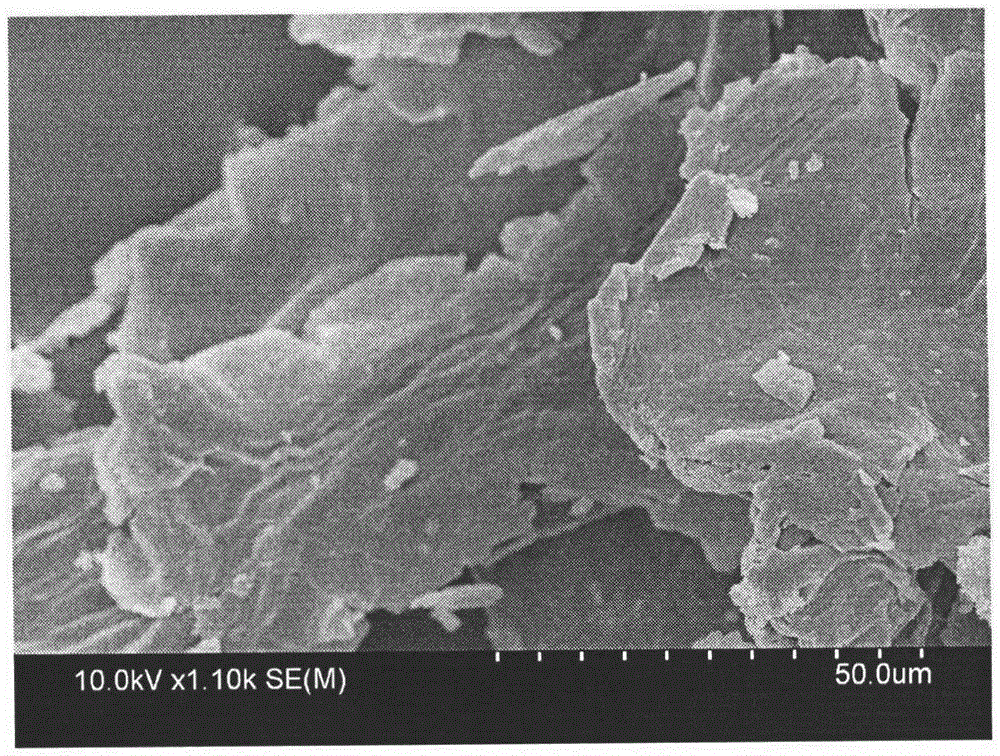

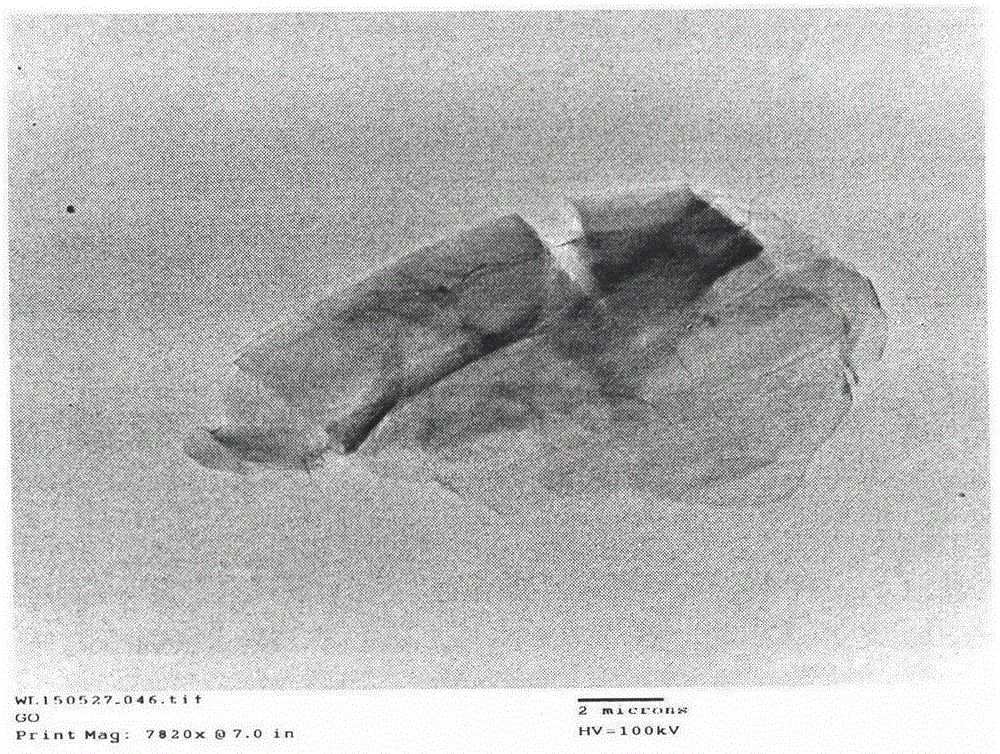

[0022] (5) Freeze-dry at about -60°C for 24 hours, and grind it into powder to obtain graphene oxide (GO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com