Formula and manufacturing method for migration-free odorless natural reclaimed rubber

A technology of natural reclaimed rubber and a production method, which is applied to the formulation of non-migration, odorless natural reclaimed rubber and its production field, can solve the problems of large odor and low physical properties, and achieve the effect of no migration of surface appearance.

Inactive Publication Date: 2016-03-16

TIANJIN RUBBER IND RES INST

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Aiming at the deficiencies of the existing natural regenerated rubber technology, the purpose of the present invention is to solve the defects that the use of pine tar and other vegetable oils has a strong odor, the use of aromatic oils migrates, and the physical properties are not high during the manufacturing process of reclaimed rubber, and provides a non-migration, odorless natural rubber. Reclaimed rubber formula and its production method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0037] Embodiment: a kind of non-migration, tasteless natural regenerated rubber, in parts by mass:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

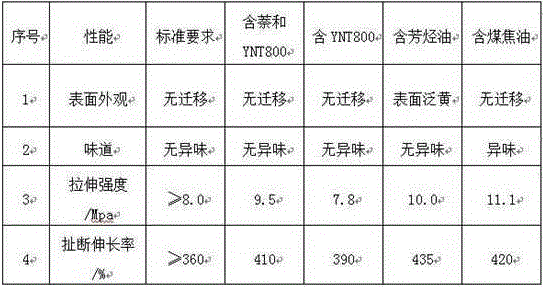

The invention provides a formula for migration-free odorless natural reclaimed rubber, which belongs to the field of rubber. The manufacturing method comprises the following steps: on the basis of 100 parts of natural rubber powder, weighing and mixing the natural rubber powder, an activator 480, YNT800, naphthalene and sodium bicarbonate; adding the mixed substances into a desulphurization tank, heating the desulphurization tank to 200 DEG C, maintaining the temperature for about 120 min, releasing gas every half an hour, and maintaining a pressure of 2.5 MPa for 30 min under the condition of a temperature of 200 DEG C; after completion of desulphurization, carrying out batching off; and then carrying out performance detection. The invention has the following advantages: naphthalene exerts activation effect in the preparation of the reclaimed rubber, can improve the physical properties of the reclaimed rubber and enables the phenomenon of migration not to occur; sodium bicarbonate is used for neutralizing acidic gas produced in the process of desulphurization; and with the formula containing naphthalene and YNT800, all the performance indexes of the reclaimed rubber meet standard requirements, and the reclaimed rubber is free of migration on its surface and free of odor.

Description

technical field [0001] The invention relates to the technical field of reclaimed rubber, in particular to a non-migration, odorless natural regenerated rubber formula and a preparation method thereof. Background technique [0002] Due to the low cost, natural reclaimed rubber has a wide range of applications in the rubber industry. Vegetable oils such as pine tar or mineral oils such as aromatic oil are generally used in the softening system in traditional natural reclaimed rubber production technology. The use of pine tar oil has excellent physical properties, but it has a strong odor and cannot be used in many occasions; the use of aromatic oil has no odor, but its strength and elongation can be used, and the reclaimed rubber turns yellow and migrates on the surface. Contents of the invention [0003] Aiming at the deficiencies of the existing natural regenerated rubber technology, the purpose of the present invention is to solve the defects that the use of pine tar and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L7/00C08L91/00C08K3/26C08K5/01C08J11/20

CPCC08J11/20C08J2307/00C08L7/00C08L2205/025C08L2205/03C08L91/00C08K3/26C08K5/01Y02W30/62

Inventor 原晓城王传东

Owner TIANJIN RUBBER IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com