Press-in type repairing method for hot blast heater top heat-resisting lining

A hot blast stove and push-in technology, applied in brick blast furnaces and other directions, can solve the problems of high temperature oxidation of the top steel shell, affecting production efficiency, and large workload, achieving the effects of less labor, lower maintenance costs, and lower costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

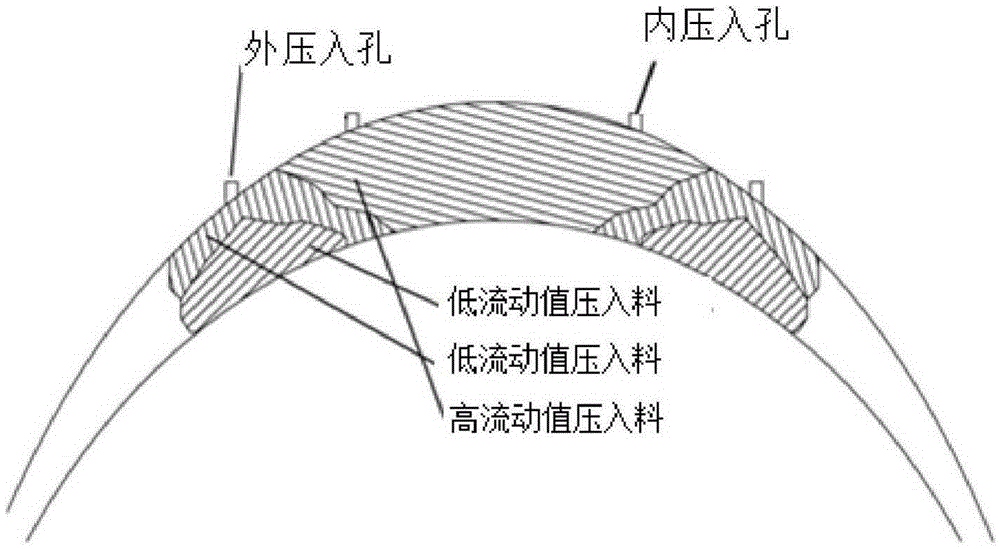

[0035] First, when the wind is stopped, measure the size range of the gap between the top steel plate and the refractory lining, estimate the amount of materials used according to the size of the gap, and distribute the types of materials pressed in by the three wheels in proportion after the amount is determined.

[0036] A press-fit repair method for the heat-resistant inner lining of the roof of a hot blast stove, which specifically includes the following steps:

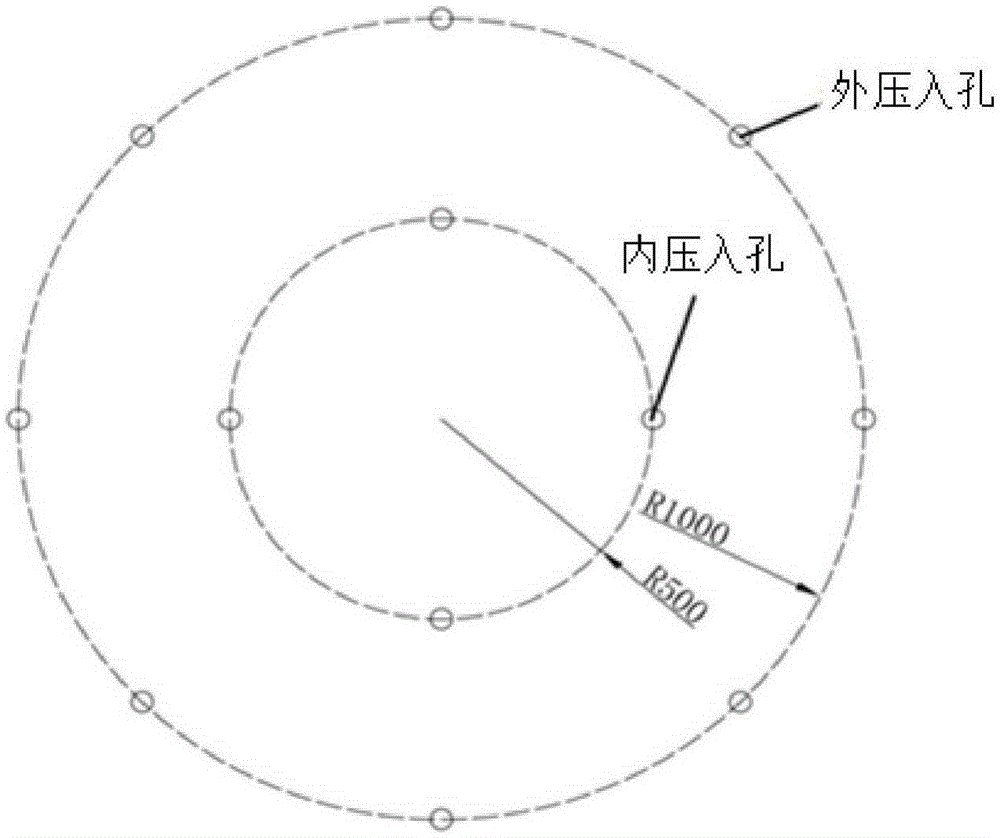

[0037] According to the size of the gap between the top steel plate and the refractory inner lining, an appropriate number of press-in holes are opened in layers from the center of the hot blast stove top to the circumference to the periphery. Refer to figure 1 , taking the center of the furnace roof as the center of the circle, the press-in holes includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap