A light-duty truss bridge integrated layer full-width construction device and its construction method

A technology of integrated layer and construction device, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of poor control of the pulling, poor pulling line and depth, poor flatness control, etc., to achieve flatness And the effect of more cleanliness, better flatness and cleanliness, and less chance of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

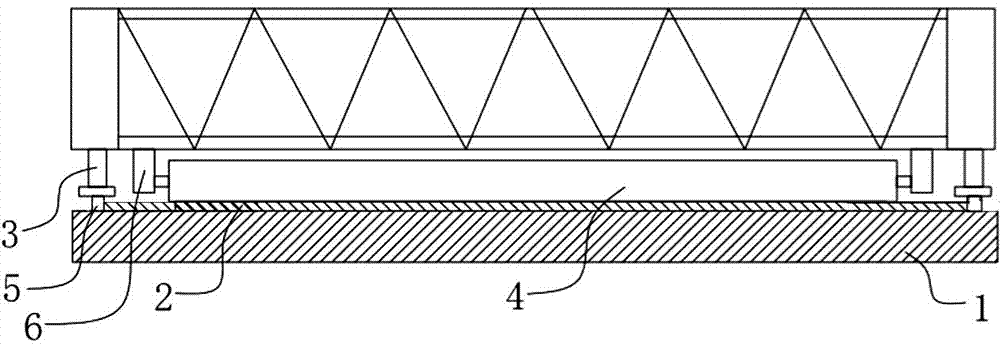

[0044] Such as figure 1As shown, the full-width construction device for the integrated layer of the light truss bridge in this embodiment includes a vibrating beam for forming the integrated layer 2 by vibrating on the base layer of the bridge deck. There is a walking wheel 3 between them, and the bottom of the vibrating beam is provided with a vibrating pulp lifting roller shaft 4, the length of the vibrating pulp lifting roller shaft 4 is equal to or less than the width of the integrated layer 2, specifically, in this embodiment, the bridge deck Both sides of the base layer are connected with a guide rail 5 through the steel support frame. The guide rail 5 extends along the length direction of the bridge deck base layer. There are walking devices at the left and right ends, and a guide rail 5 and a walking wheel 3 are arranged on both sides of the bridge deck base 1 to form a linear walking guide mechanism along the length direction of the bridge deck base 1, so that the vib...

Embodiment 2

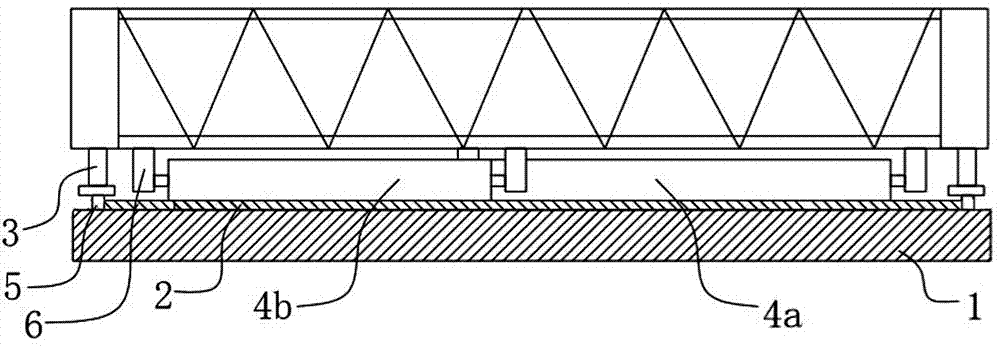

[0046] Such as figure 2 As shown, different from Embodiment 1, the vibrating pulp extraction roller 4 in this embodiment includes a first roller 4a and a second roller 4b, and in the length direction of the bridge deck base 1, the first roller 4a and the second roller The two roller shafts 4b are arranged staggered front and back, the total length of the first roller shaft 4a and the second roller shaft 4b after the interleaving is less than the width of the integrated layer 2, and the width difference is 50cm-100cm, and the width difference between the left and right sides is also determined by The construction workers carry out manual construction along with the vibration beam travel, and through such two rollers one after the other form a vibrating slurry lifting roller 4 covering the entire width of the bridge deck base 1, which is beneficial to the formation of the bridge deck base 1. Overall layer 2 flatness and cleanliness.

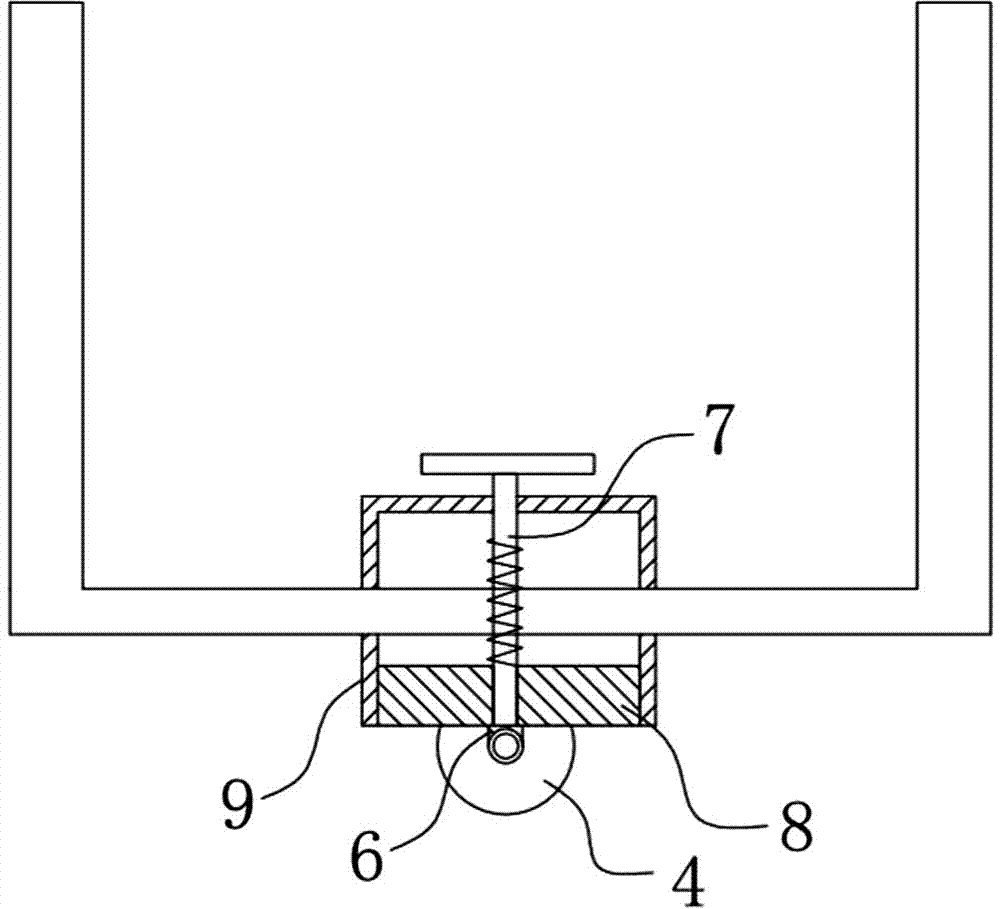

[0047] Additionally, if Figure 4 As show...

Embodiment 3

[0052] see Figure 5 As shown, the difference from Embodiment 2 is that lighting devices are arranged at intervals on the vibrating beam to facilitate construction at night.

[0053] The integrated layer 2 is C40 concrete with a thickness of 10cm, its width is 15m to 17m, and its length is divided into three sections with a total length of 290m to 300m. During the progress, the width of the integrated layer 2 is fully constructed, and the length of the integrated layer 2 is constructed one by one. The specific construction steps are as follows:

[0054] Step 1: Chiseling away scum and cleaning the base of the bridge deck: Manually chisel away the places where there are cement laitance and oil stains locally to ensure that there is no concrete laitance, floating dust and other sundries on the top surface. Rinse the top surface of the T-beam with an air compressor or a high-pressure water gun after finishing.

[0055] Step 2: Carry out measurement and lofting on the base of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com