Garbage conveying system of purely sweeping type road motor sweeper

A garbage transportation and road cleaning technology, which is applied in road cleaning, cleaning methods, construction, etc., can solve the problems of difficulty in unloading garbage, no dust cover, high investment cost, etc., to reduce secondary pollution, good avoidance effect, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

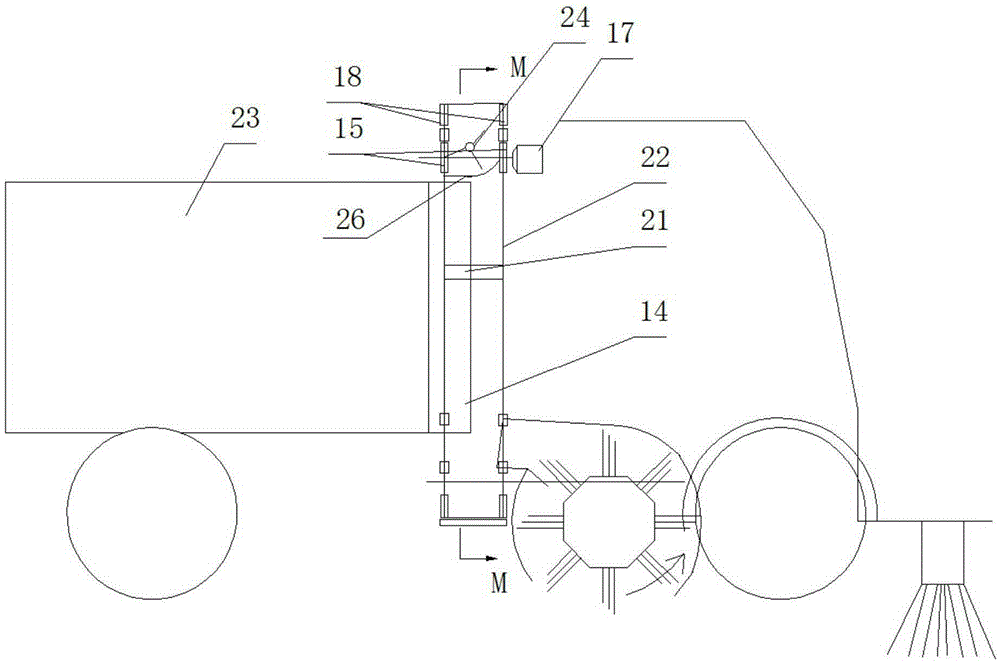

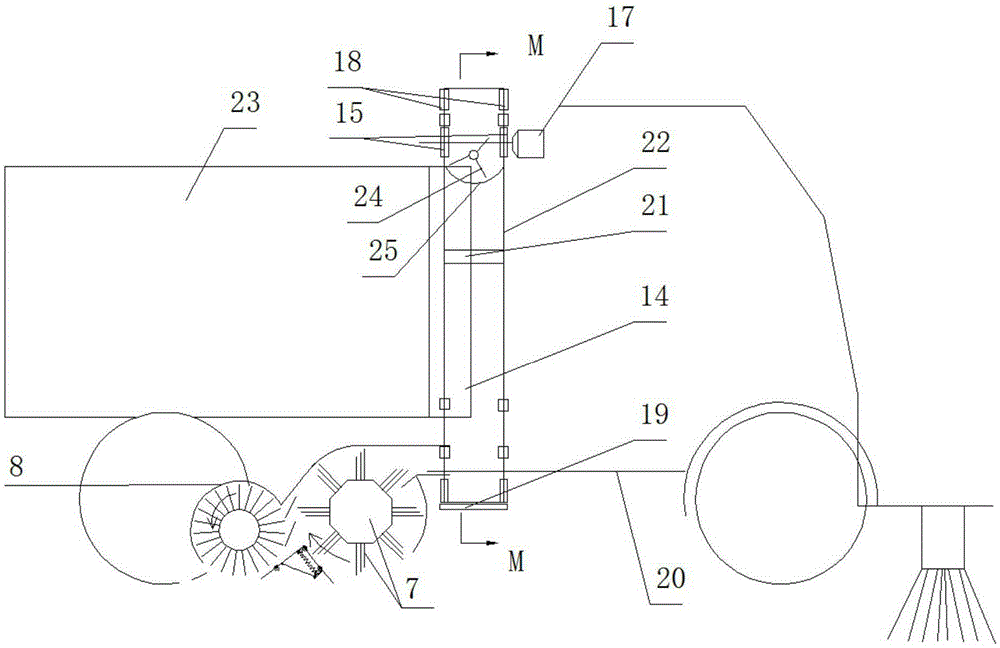

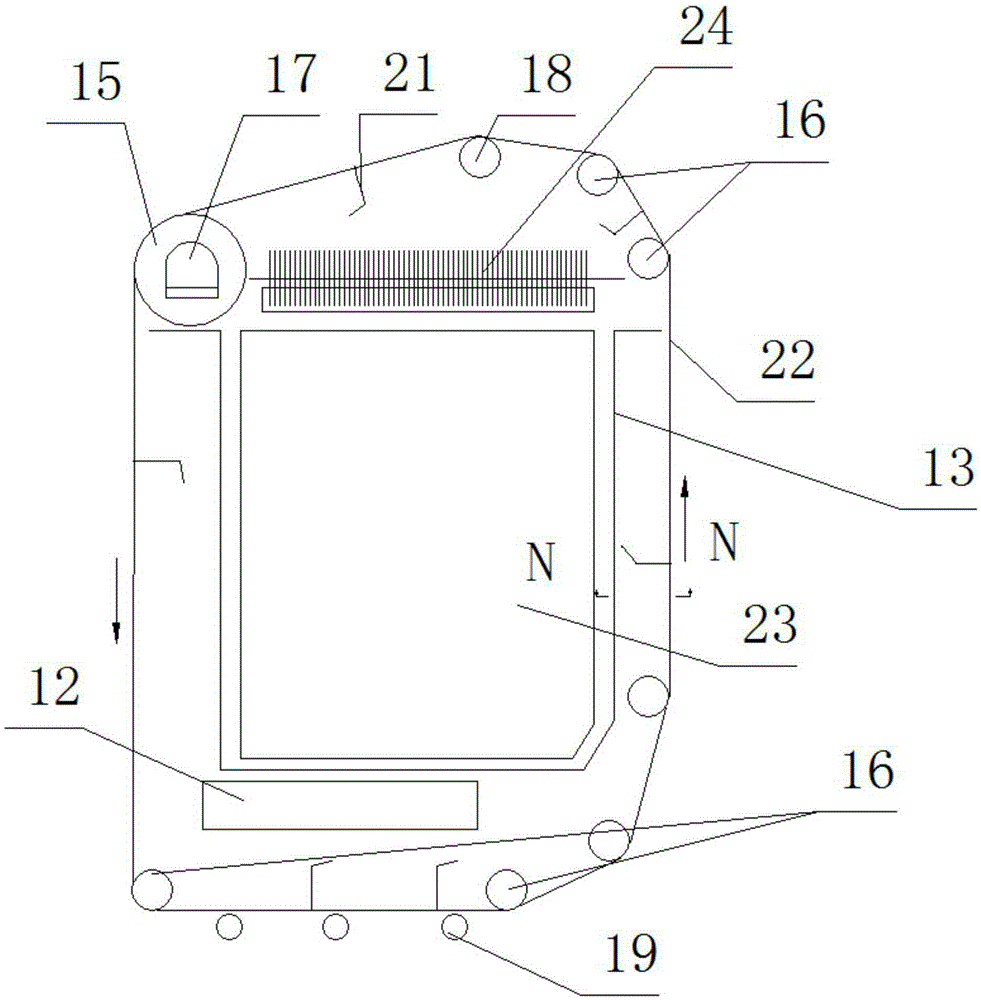

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, the present invention is a pure sweeping road sweeper garbage conveying system, including rolling sweeping cleaning mechanism, garbage conveying system, garbage bin and chassis and other components (see the structural principle for details) figure 1 ). It is characterized in that the cleaning mechanism is installed at the bottom of the chassis of the car. The rolling garbage outlet of the rolling cleaning mechanism and the conveyor belt dust cover garbage inlet 12 of the conveying system are connected in collusion with each other, and the colluding connection is a movable connection or a soft connection, so that the rolling cleaning mechanism can be independently moved up and down relative to the conveying system acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com