A solenoid valve box oil circuit switching device

A technology of oil circuit switching and electromagnetic valve, which is applied in the direction of valve device, valve operation/release device, valve details, etc. It can solve the problems of oil leakage, large leakage of spool valve type reversing valve, and stuck valve core, etc., to achieve The effect of low internal leakage and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

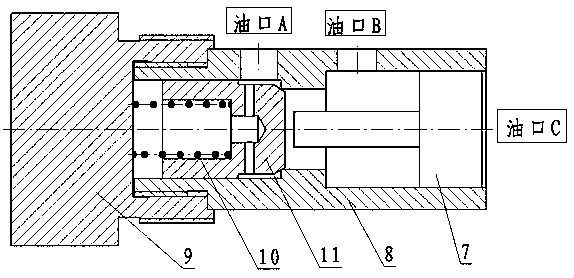

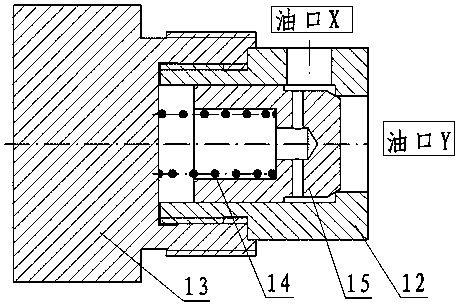

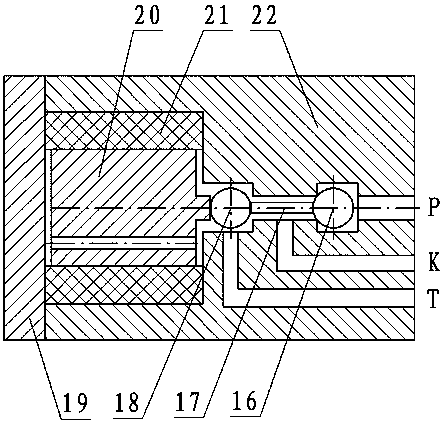

[0015] Such as figure 1 As shown, the embodiment of the present invention is a solenoid valve box oil circuit switching device, which mainly includes an integrated valve block 3, two hydraulic control check valves, two check valves and an electromagnetic ball valve. 3. There is a process oil hole inside, which communicates the oil circuit connection between two hydraulic control check valves, two check valves and electromagnetic ball valves. The integrated valve block 3 is provided with a pressure oil inlet A-1, a return valve Oil inlet A-2, pressure oil outlet X-1 and oil return outlet X-2, the two hydraulic control check valves are respectively set at pressure oil inlet A-1, oil return inlet A-2, integrated valve block 3 The inlet of the valve is closely connected with the inlet of the hydraulic control check valve. The two check valves are located at the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com