A comprehensive performance testing system for stepping motors

A comprehensive performance testing, stepper motor technology, applied in the field of testing, can solve problems such as poor testing accuracy and low testing efficiency, and achieve the effect of eliminating additional bending moments, real testing results, and improving data acquisition and resolution capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

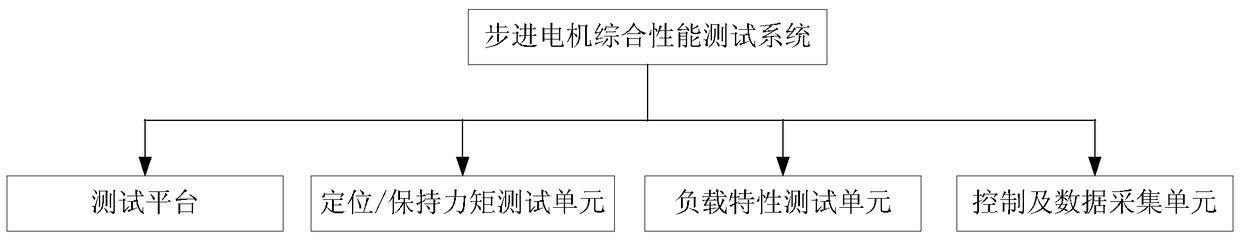

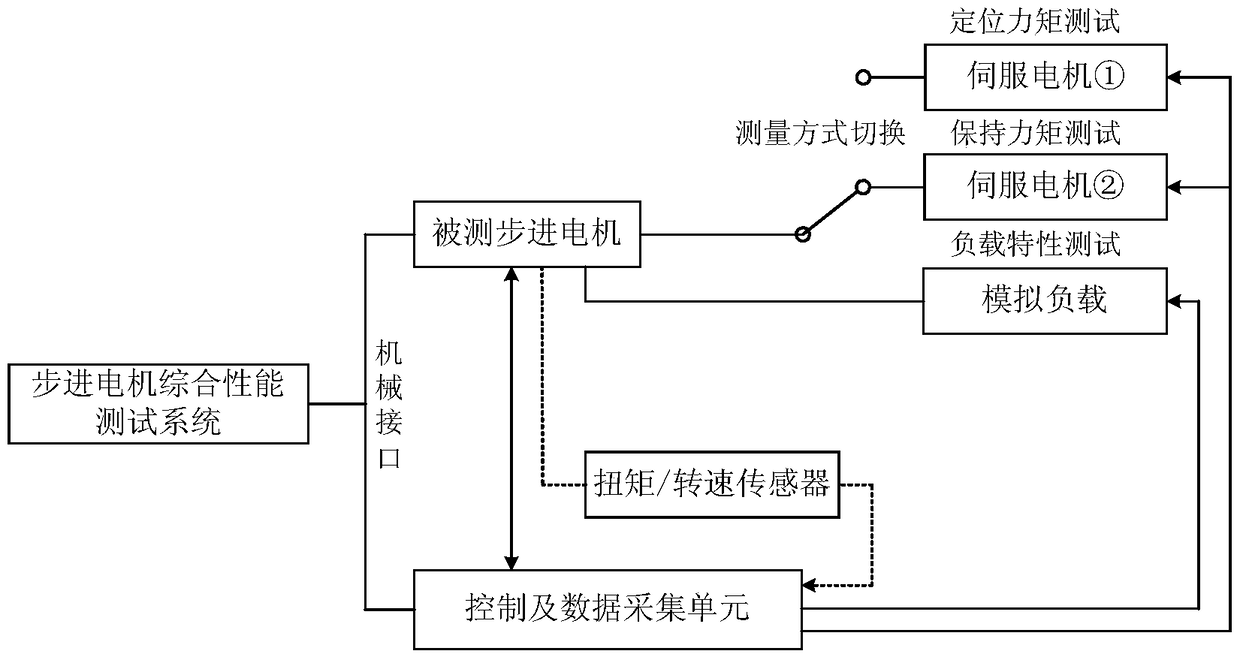

[0027] Such as figure 1 As shown, the test system of the present invention includes a test platform, a positioning / holding torque test unit, a load characteristic test unit, and a control and data acquisition unit.

[0028] The test platform is the basic platform of the system, providing mechanical interfaces for the positioning / holding torque test unit, load characteristic test unit, control and data acquisition unit.

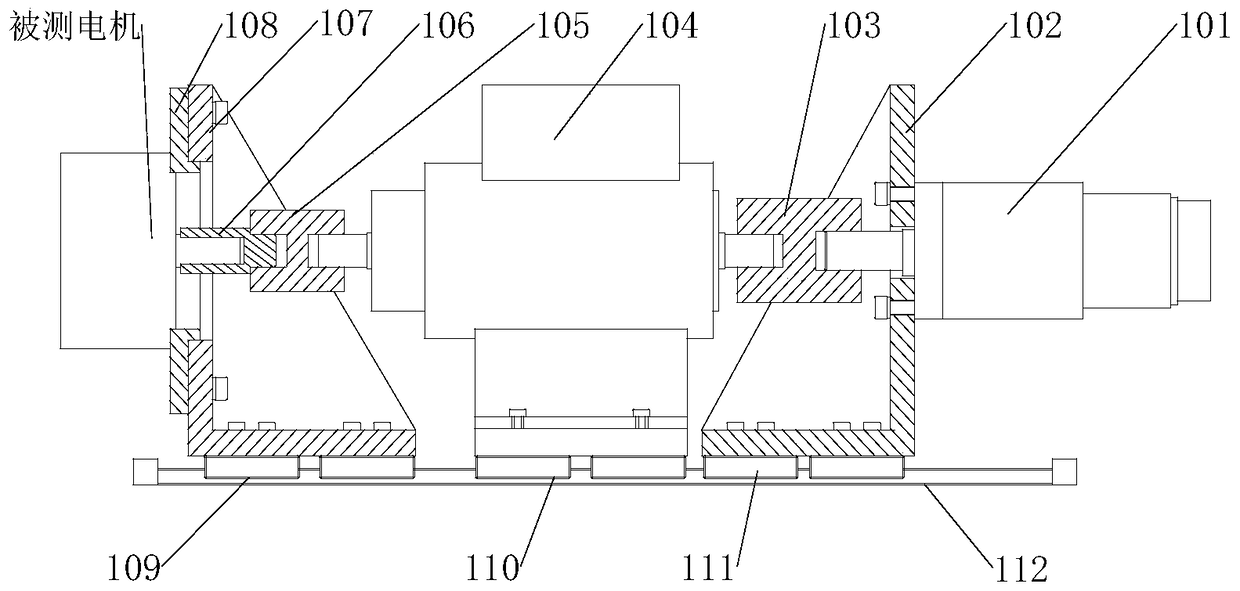

[0029] The positioning / holding torque test unit provides power input for the stepping motor under test to realize its positioning / holding torque test. Such as figure 2 As shown, preferably, the positioning / holding torque test unit consists of a servo motor 101, a motor mounting bracket 102, a first coupling 103, a torque sensor 104, a second coupling 105, an adapter shaft 106, and a motor mounting bracket to be tested. 107, an adapter flange 108, a first slider 109, a second slider 110, a third slider 111, and a guide rail 112. The servo motor 101 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com