Device for testing wind erosion of automotive catalytic converter liner products

A catalytic converter and testing equipment technology, applied in the field of wind erosion testing equipment for automotive catalytic converter gasket products, can solve the problems of inability to set gasket compression density at the same time, inability to deteriorate test conditions, inability to quantify mass or volume, etc. , to achieve a wide range of equipment testing, shorten the test time, and achieve a significant simulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

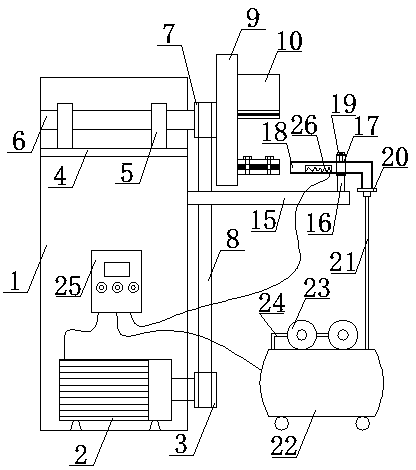

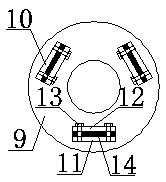

[0020] like figure 1 , 2 As shown, a wind erosion test equipment device for automotive catalytic converter gasket products, including a frame body 1, a driving motor 2, a driving wheel 3, a horizontal plate 4, a bearing seat 5, a rotating shaft 6, a driven wheel 7, a belt 8, a rotating Disk 9, clamping part 10, outer splint 11, inner splint 12, fixing bolt 13, test liner 14, cantilever plate 15, support column 16, positioning pipe 17, air nozzle 18, positioning bolt 19, connecting flange 20 , connecting hose 21, air compressor 22, air pump 23, air intake pipe 24, control box 25 and heating resistance wire 26, described drive motor 2 is fixedly installed on the bottom of frame body 1; Described drive wheel 3 is installed on the described On the output shaft of the driving motor 2; the top of the frame body 1 is provided with a horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com