Current linear control circuit for constant current source

A technology of linear control and constant current source, applied in the direction of control/regulation system, regulation of electrical variables, instruments, etc., can solve the problems of easily damaged electrical components, rapid circuit changes, inconvenient adjustment, etc., to achieve stable circuit performance and prevent current Too large to avoid damage to electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

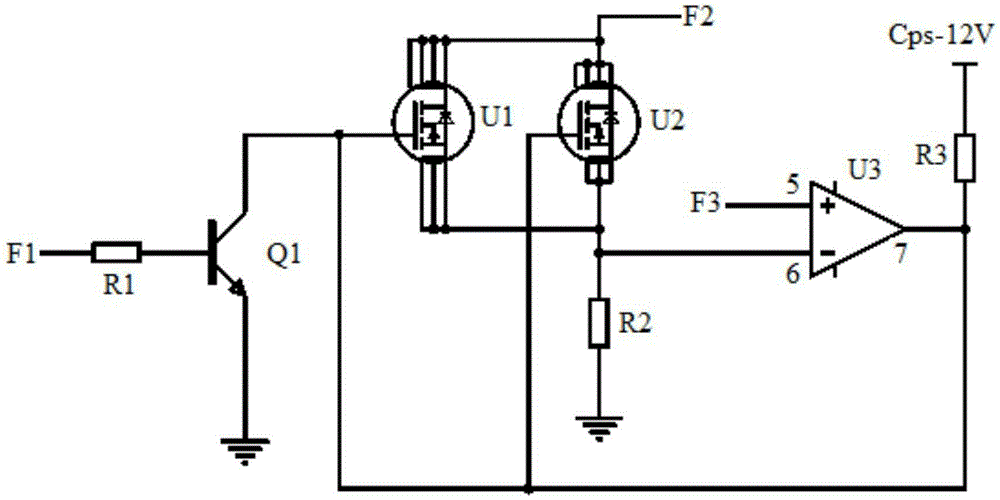

[0019] like figure 1 As shown, the current linear control circuit for a constant current source of the present invention includes: a triode Q1, a first field effect transistor U1, a second field effect transistor U2, an operational amplifier U3, a first resistor R1, a second resistor R2, The third resistor R3.

[0020] The base of the triode Q1 is connected to the first network node F1 through the first resistor R1, the emitter of the triode Q1 is grounded, and the collector of the triode Q1 is connected to the gate of the first field effect transistor U1 and the The gate of the second field effect transistor U2. In this embodiment, the triode Q1 is an NPN low-power triode whose model is 9013. The function of the transistor Q1 is to switch and control the gate of the first field effect transistor U1. The first network node F1 is a control terminal for controlling the on-off of the triode Q1, the first resistor R1 is a current-limiting base resistor, and the first resistor R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com