Long-Life Supercritical Carbon Dioxide Cooled Small Reactors

A carbon dioxide and supercritical technology, applied in the direction of moderator/core structure, reactor, reactor fuel element, etc., can solve the problem of reducing the stable temperature of the fuel, and achieve the effect of increasing the stable temperature, reducing complexity, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

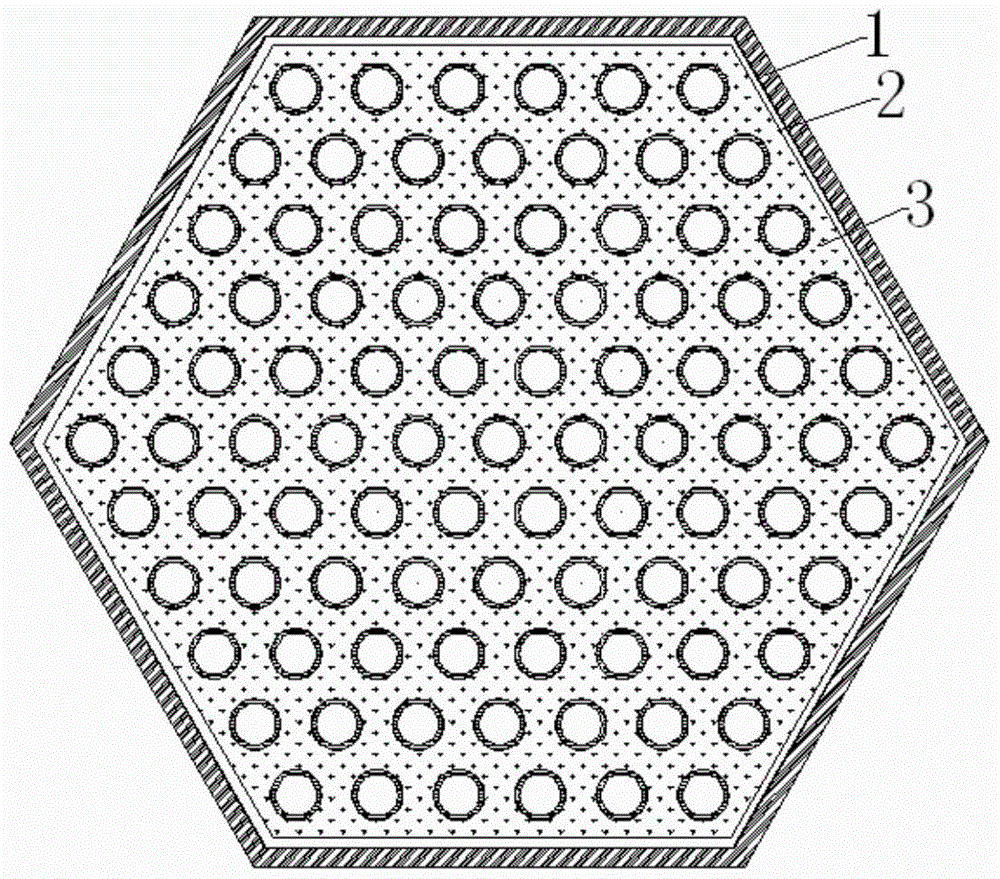

[0027] Such as figure 1 As shown, a kind of honeycomb fuel assembly of the present invention, this fuel assembly is hexagonal, has three layers altogether from outside to inside, is assembly wall 1 and air gap layer 2 respectively, is filled with fuel region 3 in air gap layer 2, fuel There are 91 coolant channels evenly distributed in zone 3.

[0028] Preferably, the material filled in the fuel zone 3 is MOX fuel.

[0029] Preferably the material of the inner component wall is ODS MA956 stainless steel.

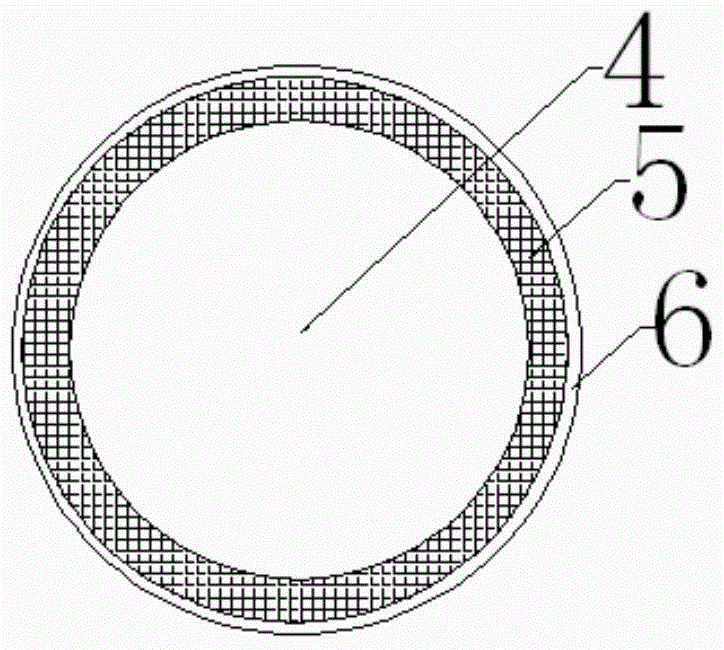

[0030] Such as figure 2 As shown, the coolant passage is composed of a coolant 4, a coolant wall 5 and an air gap 6 between the coolant passage wall and the fuel.

[0031] Preferably, the material of the coolant wall 5 is ODS MA956 stainless steel.

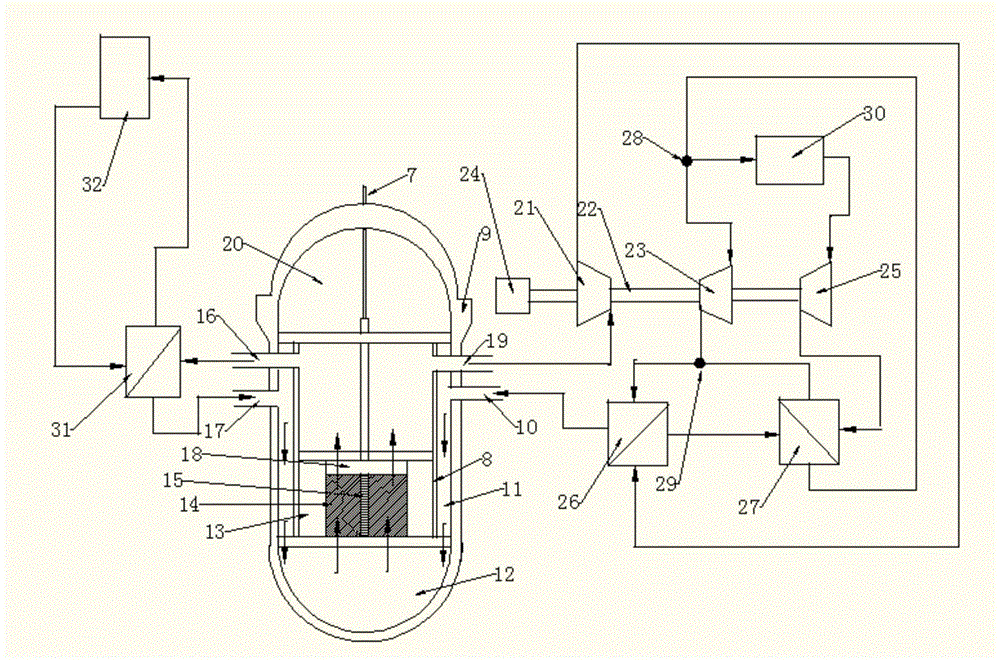

[0032] Such as image 3 As shown, it is a long-life supercritical carbon dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com