Electrolytic capacitor manufacturing method and product thereby

A technology for electrolytic capacitors and manufacturing methods, applied in the direction of electrolytic capacitors, solid electrolytic capacitors, capacitors, etc., capable of solving problems such as increased cost of dispersion liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following are examples, but the contents of the present invention are not limited to the scope of these examples.

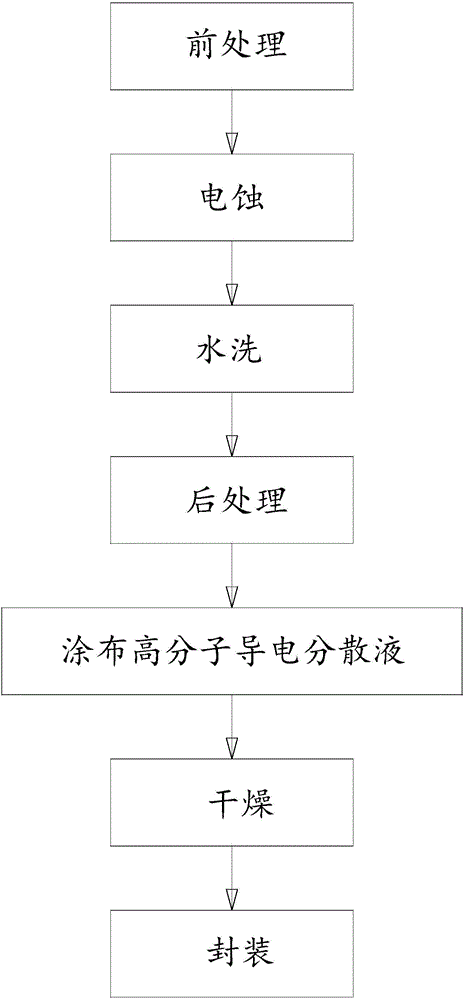

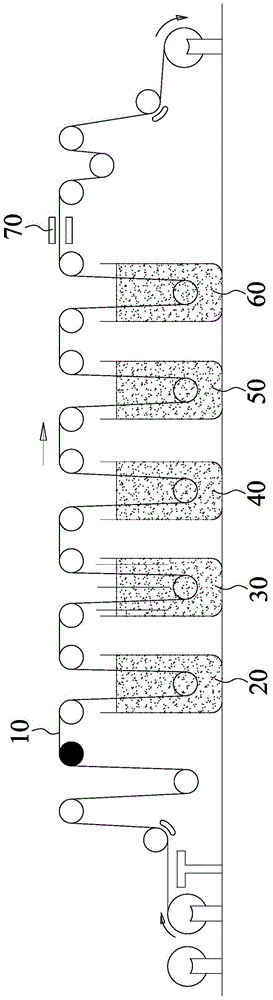

[0009] Please refer to figure 1 and figure 2 Shown is a flow chart of the steps of the manufacturing method of the electrolytic capacitor of the present invention and a schematic diagram of the production process of the aluminum foil for electrodes. The steps of the capacitor manufacturing method of the present invention include pretreatment, electroerosion, water washing, posttreatment, coating of polymer conductive dispersion, drying and packaging; wherein:

[0010] The pretreatment steps are: passing the aluminum foil 10 through the pretreatment tank 20 and cleaning the aluminum foil 10 with water.

[0011] The steps of electro-etching include: passing the aluminum foil 10 through the electro-etching tank 30 , passing through the corrosive solution and electrifying the aluminum foil 10 to electrolyze, and forming pits on the aluminum foil 10 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com