Double-reed temperature controller

A thermostat, double reed technology, applied in the direction of thermal switch parts, etc., can solve the problems of poor contact, thermostat contact carbonization, compressor damage, etc., to reduce the probability of contact coking and meet the start-up requirements. need, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

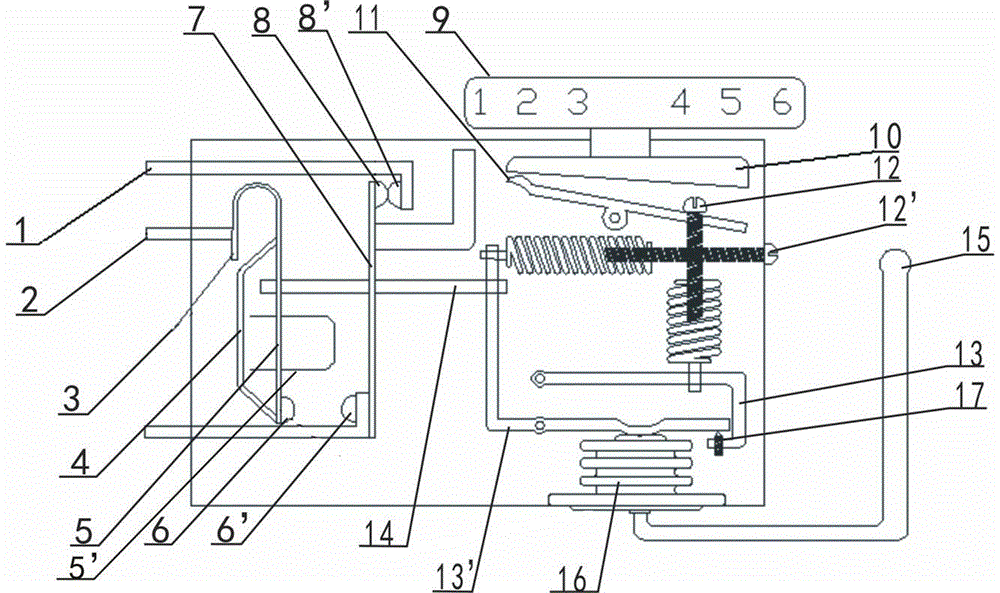

[0007] The technical features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0008] See the accompanying drawings, it consists of grounding terminal (1), connecting terminal (2), longitudinal "U" spring (3), transverse "U" spring (4), moving straight spring (5), reverse elastic piece (5) '), moving contact (6), static contact (6'), static straight spring (7), normally closed moving contact (8), normally closed static contact (8') constitute the opening and closing system. Temperature knob (9), cam (10), adjustment rod (11), stop temperature adjustment screw (12), start temperature adjustment screw (12'), hook-shaped lever (13), "L"-shaped lever (13') , horizontal push rod (14), capillary temperature sensing probe (15), bellows (16), stop temperature fine-tuning screw (17) constitute adjustment system, constitute the present invention by opening and closing system and adjustment system.

[0009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com