A kind of oled screen body and preparation method thereof

An electrode layer and substrate technology, applied in the field of OLED, can solve the problems of reducing the efficiency roll-off and efficiency reduction of the screen body, and achieve the effects of improving the brightness, suppressing the efficiency roll-off, and improving the uniformity of light emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A scattering film layer 1 is arranged on the outside of the substrate

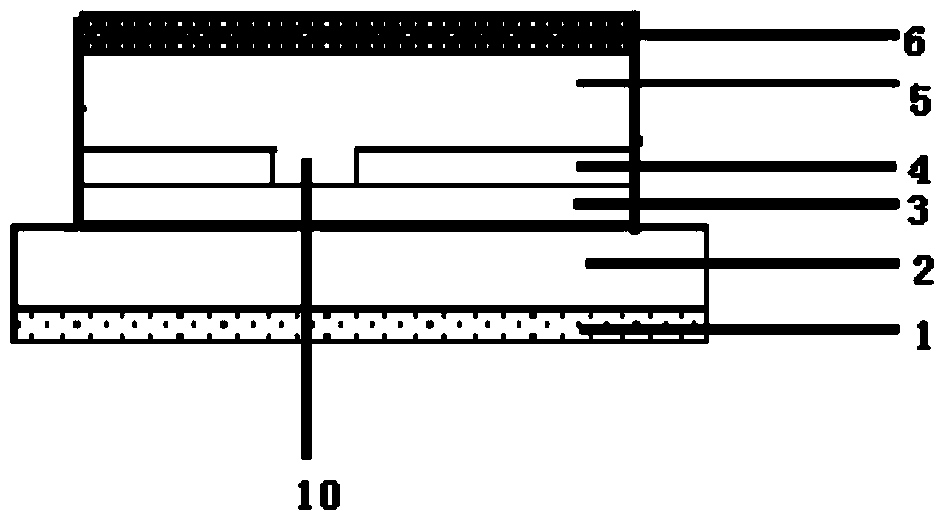

[0031] Such as figure 1 with Figure 4 As shown, a relatively bright OLED panel provided by the present invention includes a substrate 2 and a first electrode layer 3, an organic light-emitting layer 5 and a second electrode layer 6 are stacked on the substrate 2. An insulating film layer is arranged between an electrode layer 3 (anode) and the organic light-emitting layer 5, such as Figure 4 with Figure 5 As shown, the insulating film layer is etched to form parallel or criss-cross light-emitting regions 10, the width of each light-emitting region 10 is 5nm-500um, preferably 50nm-100um, between adjacent light-emitting regions 10 The width of the insulating material layer 4 is 10nm-100um. The thickness of the insulating film layer is 5-20nm. As other implementation manners, the insulating film layer may also be Image 6 with Figure 7 As shown, its light-emitting area is a para...

Embodiment 2

[0037] Embodiment 2 A scattering film layer 1 is arranged between the substrate and the first electrode layer

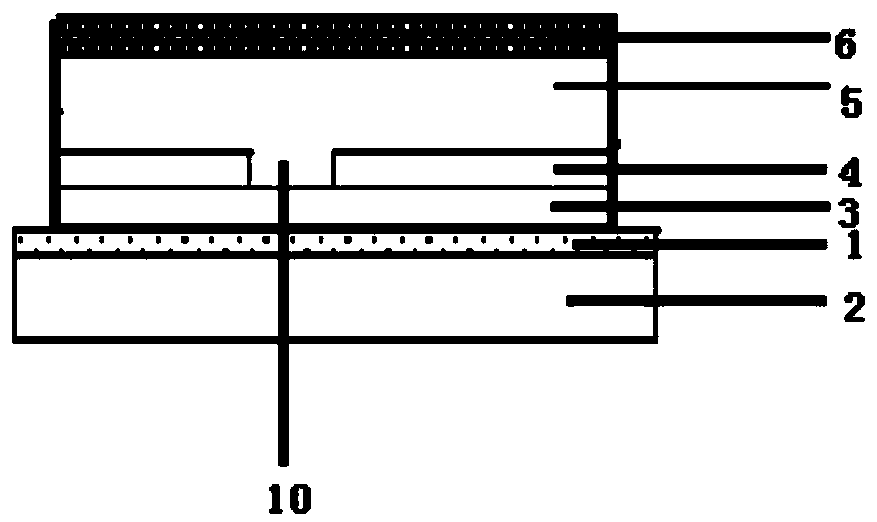

[0038] The structure of a relatively bright OLED screen body provided in this embodiment is the same as that in Embodiment 1, such as figure 2 As shown, the scattering film layer 1 is arranged between the substrate 2 and the first electrode layer 3 .

[0039]The preparation method is to arrange a scattering film layer 1 on the substrate 2, coat a layer of insulating film layer on the scattering film layer 1, and the width of the insulating material layer 4 between the adjacent light-emitting regions is 10nm-100um, and then pass the electron beam Photolithography technology carries out photoetching to etch out the light-emitting region 10, the width of the light-emitting region 10 is 5nm-500um, preferably the width is 50nm-100um, and then vapor-deposits the first electrode layer 3, the organic light-emitting layer 5 and the second electrode layer 6 ( cathode), packa...

Embodiment 3

[0040] Embodiment 3 The scattering film layer 1 is respectively arranged on both sides of the substrate

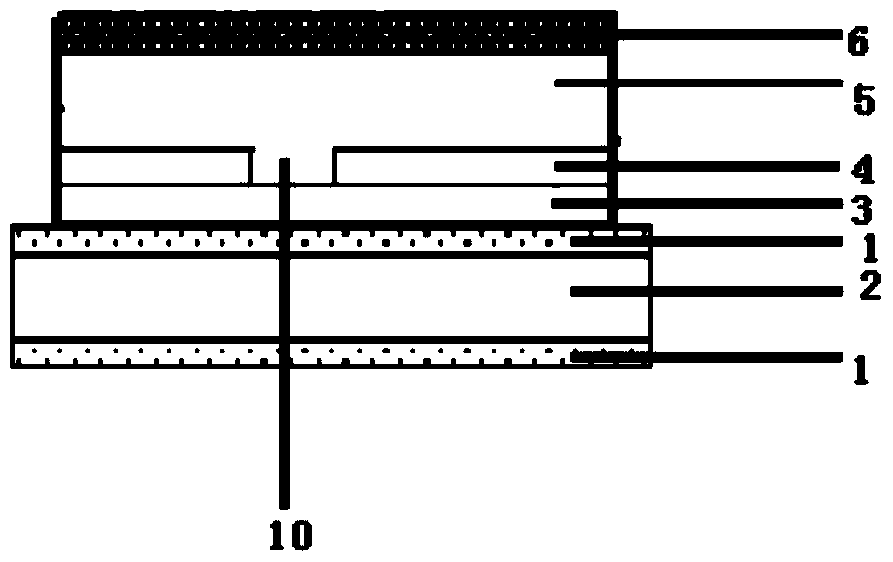

[0041] The structure of a relatively bright OLED screen body provided in this embodiment is the same as that in Embodiment 1, such as image 3 As shown, the two sides of the substrate are respectively provided with scattering film layers 1, that is, one of the scattering film layers 1 is provided between the substrate 2 and the first electrode layer 3, and the other scattering film layer 1 is provided between the The side of the substrate away from the first electrode layer.

[0042] The preparation method is as follows: setting an upper scattering film layer 1 on the substrate 2, coating a layer of insulating film layer on the scattering film layer 1, and then performing photolithography to etch a light-emitting region 10 by electron beam lithography technology. The width of the light-emitting region 10 is 5nm-500um, the preferred width is 50nm-100um, the width of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com