High-precision control method for overlap amount of disc scissors

A control method and a technology of overlapping amount, which are applied in the direction of automatic control devices, shearing machine accessories, shearing devices, etc., can solve the problems of ignorance of precision, no record of precision values, complex control methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

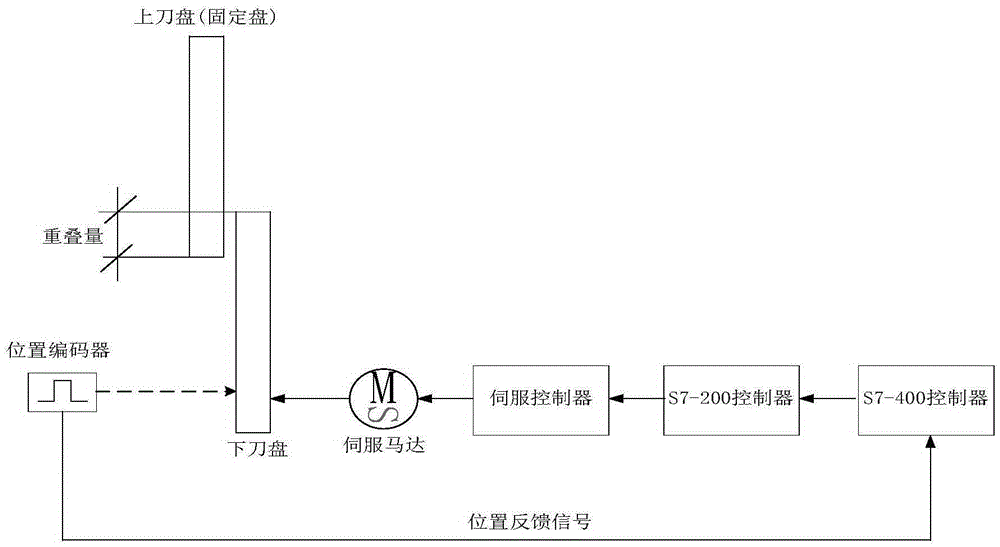

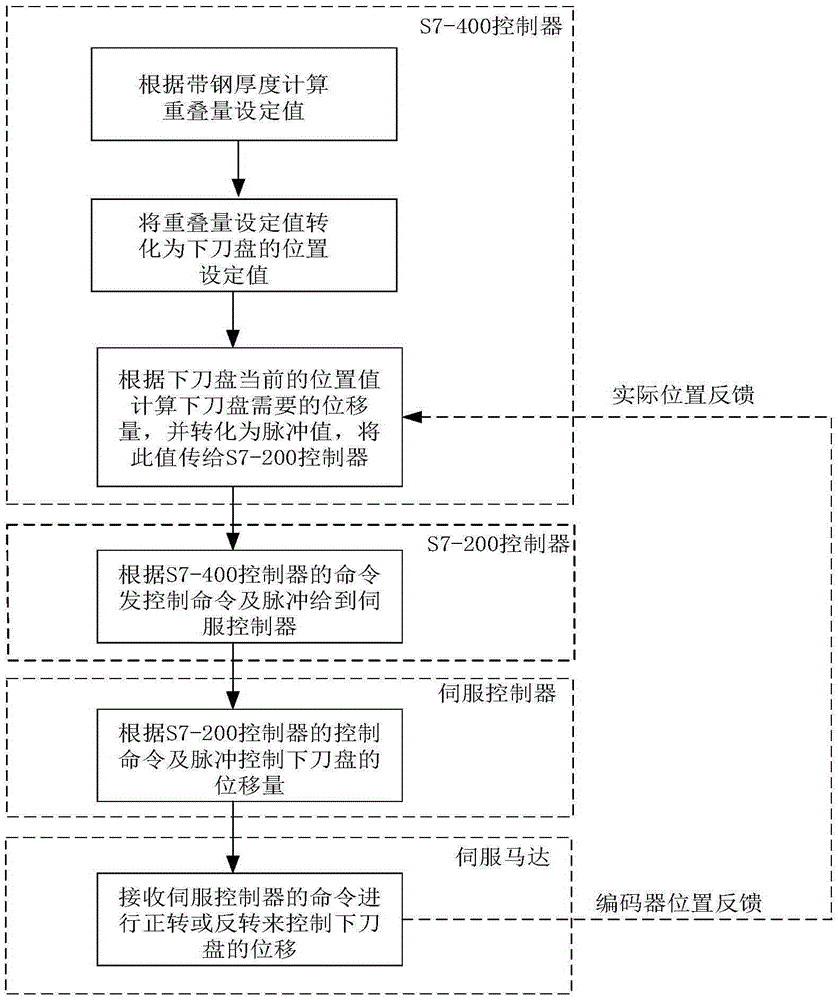

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A control method for the overlapping amount of high-precision disc shears, including inner ring control, outer ring control, upper cutter head and lower cutter head, wherein the upper cutter head is fixed, and the lower cutter head can be controlled to move up and down by the inner ring, and the outer ring The control determines the actual position of the lower cutter head through the absolute encoder, and then compares it with the position of the overlapping amount that needs to be set to determine the distance that the lower cutter head needs to move, and transmits the required control amount to the inner loop control. The inner loop control calculates the number of output pulses according to the amount of movement required, and drives the servo motor to drive the lower cutter head up and down through the servo controller, thereby realizing high-precision contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com