External power high-speed train

A technology of high-speed trains and external power, applied in the direction of railway car bodies, parts of railway car bodies, transmission devices driven by electric motors, etc., can solve the problems of insufficient nuclear power plants, etc., and achieve the effects of improving safety factor, reducing weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

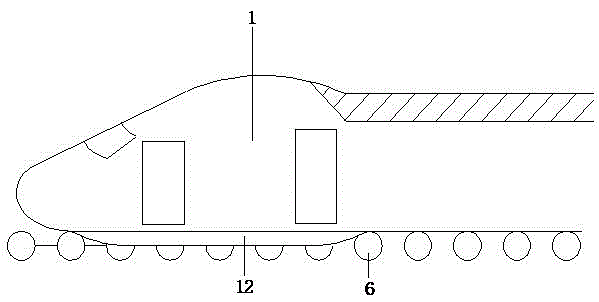

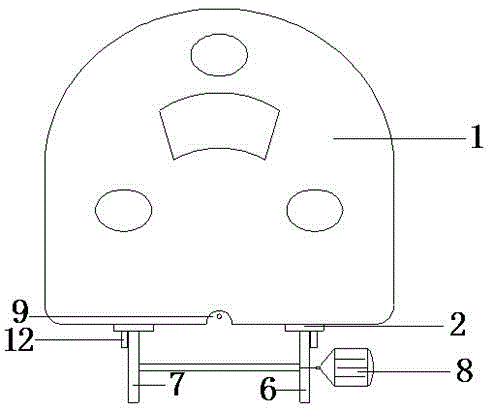

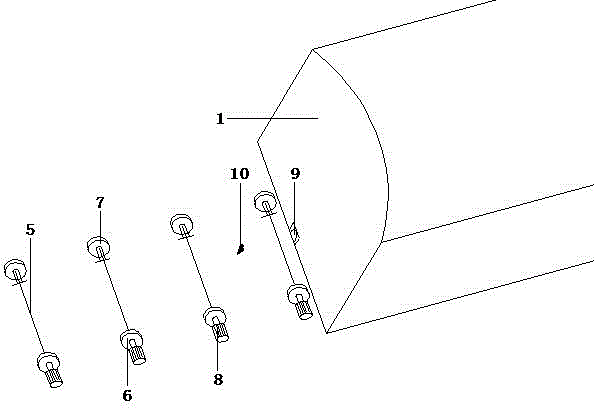

[0022] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a car body 1, track plates 2 are symmetrically arranged on both sides of the bottom of the car body 1, and a base 4 arranged at intervals on the wheel pair pillow 3 is arranged under the car body 1, and a power wheel set is erected on the base 4. , the power wheel pair is the driving wheel 6 and the driven wheel 7 connected by the drive shaft 5, the positions of the driving wheel 6 and the driven wheel 7 correspond to the track plate 2, and the driving motor 8 is connected on the driving wheel 6; several adjacent driving motors 8 to form a power group, and the power group is connected to the remote control device on the car body 1 through a signal receiver; the bottom middle of the car body 1 is provided with a receiving tank cable 9, and the corresponding ground below the car body 1 is evenly spaced with engines. The electric column 10 and the electric column 10 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com