Treatment system and method for treating pre-treatment wastewater of electroplating

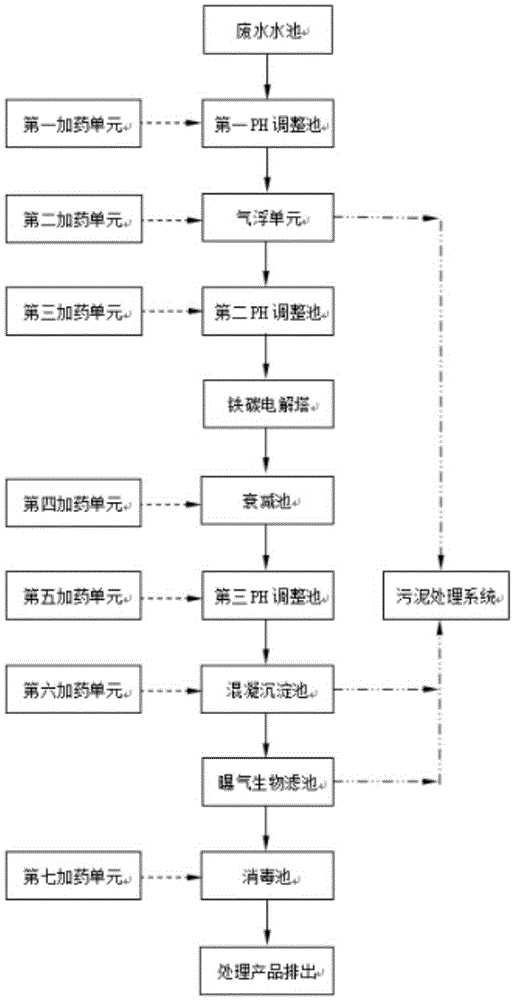

A technology of electroplating pretreatment and treatment system, which is applied in the direction of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. It can solve the problem that the quality of discharged water cannot meet the discharge standards of electroplating pollutants, and it cannot solve the problem of mixed discharge of mud and water , unstable operation and other problems, to achieve the effect of improving the accuracy of dosing, reducing the cost of medicine, and improving the pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a hardware electroplating factory, wastewater before electroplating was used as the first sample. The water quality of the first sample to be treated is shown in Table 1:

[0023] Table 1: Influent water quality of the first sample

[0024] water quality index

pH

COD

NH 3 -N

Fe

Zn

concentration

4.50

560

40

75

40

[0025] (unit: mg / l, except pH)

[0026] Step 1, the first sample enters the first pH adjustment tank, the first sample is adjusted for the first time in the first pH adjustment tank, and sodium hydroxide is added to the first pH adjustment tank through the first dosing unit, and the second The time for a pH adjustment is 20 minutes, and the pH of the generated first waste liquid is 8.5;

[0027] Step 2, the first waste liquid enters the air flotation unit, the electrolytic properties of the first waste liquid are adjusted in the air flotation unit, and polyaluminum chloride with a basicity of...

Embodiment 2

[0041] In a hardware electroplating industrial park, wastewater before electroplating was used as the second sample. The water quality of the second sample to be treated is shown in Table 3:

[0042] Table 3: Influent water quality of the second sample

[0043] water quality index

pH

COD

NH 3 -N

Fe

Zn

concentration

3.20

650

30

65

50

[0044] (unit: mg / l, except pH)

[0045] Step 1, the second sample enters the first pH adjustment tank, the first sample is adjusted for the first time in the first pH adjustment tank, and sodium hydroxide is added to the first pH adjustment tank through the first dosing unit, the first The time for secondary pH adjustment is 20 minutes, and the pH of the first waste liquid generated is 8.5;

[0046] Step 2, the first waste liquid enters the air flotation unit, the electrolytic properties of the first waste liquid are adjusted in the air flotation unit, and polyaluminum chloride w...

Embodiment 3

[0060] A certain electroplating director, the wastewater before electroplating was used as the third sample. The water quality of the third sample to be treated is shown in Table 5:

[0061] Table 5: Influent water quality of the third sample

[0062] water quality index

pH

COD

NH 3 -N

Fe

Zn

concentration

6.20

400

45

55

42

[0063] (unit: mg / l, except pH)

[0064] Step 1, the third sample enters the first pH adjustment tank, the third sample is adjusted for the first time in the first pH adjustment tank, and sodium hydroxide is added to the first pH adjustment tank through the first dosing unit, the first time The time for pH adjustment is 20 minutes, and the pH of the generated first waste liquid is 8.5;

[0065] Step 2, the first waste liquid enters the air flotation unit, the electrolytic properties of the first waste liquid are adjusted in the air flotation unit, and polyaluminum chloride with a basicity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com