Modified treatment system for sludge

A treatment system and modified technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Sludge and other problems, to achieve the effect of low operating cost, small footprint and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

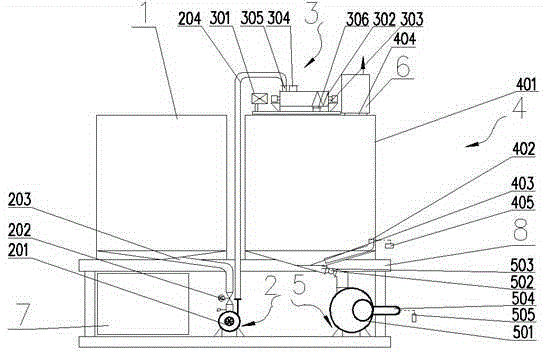

[0023] refer to figure 1 , the present embodiment includes a modified regulator tank 1, a first metering device 2, a mixing device 3, a first modified tank 4, a first cloth feeding device 5, a catalytic oxidation processor 6, an electric control device 7 and Bracket 8, modified modifier tank 1 and mixing and batching device 3 are connected through the first metering and feeding device 2, mixing and batching device 3 is connected with the first modification tank 4, and the first modification tank 4 is respectively connected with the first cloth feeding device 5. The catalytic oxidation processor 6 is connected, and the electric control device 7 is electrically connected with the first metering and feeding device 2, the mixing and batching device 3, the first reforming tank 4, the first cloth feeding device 5, and the catalytic oxidation processor 6, respectively. The modified regulator tank 1, the first metering and feeding device 2, the mixing device 3, the first modifying tan...

Embodiment 2

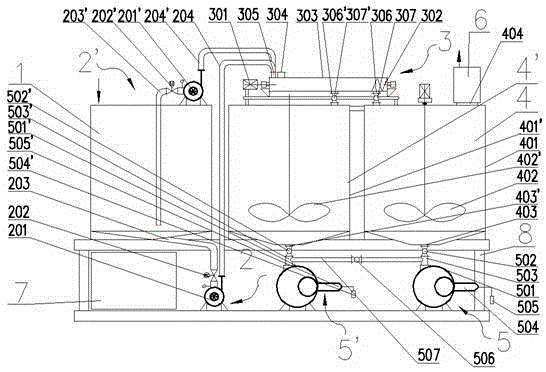

[0030] refer to figure 2, the difference between this embodiment and Embodiment 1 is only that: the first agitator 402 is a mechanical agitator, the first agitator 402 is located in the first tank body 401, and the first air compressor 405 can be omitted; The second feeding device 2', the second modified tank 4' and the second cloth feeding device 5', the second feeding device 2' includes the second feeding pump 201', the third pipeline 203' and the second feeding device 201'. Four pipelines 204', the feed inlet of the second gauge feed pump 201' is connected with the modified regulator tank 1 through the third pipeline 203', the third pipeline 203' is provided with a second pipeline valve 202', the second gauge The discharge port of the feed pump 201' is connected to the compounding device 3 through the fourth pipeline 204'; the second modification tank 4' includes a second tank body 401', a second agitator 402', and the second modification tank 4 ' communicates with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com