A production method and equipment for a powdery mes-containing composition with good fluidity

A production method and fluidity technology, applied in the direction of surface-active detergent composition, detergent composition, inorganic/elemental detergent composition, etc., can solve problems such as easy agglomeration, avoid agglomeration, and improve storage quality and safety Effects on sex and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

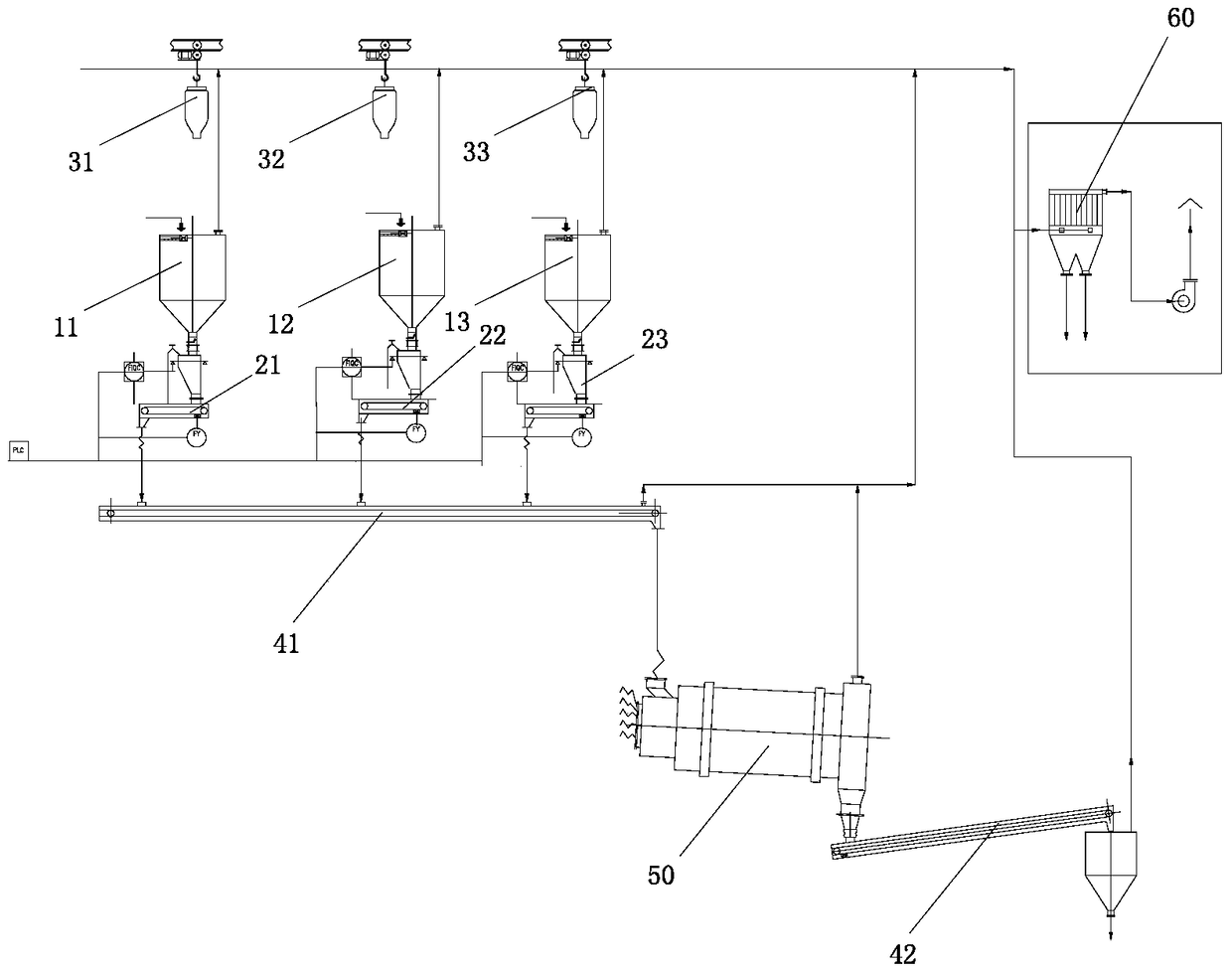

[0040] The zeolite raw material is put into the first silo 11; the Glauber’s salt raw material is put into the second silo 12; the newly ground MES raw material is put into the third silo 13; the newly ground MES first weighing scale 21 is passed through the measuring equipment Continuously weigh 75% of the total amount of the MES raw material; the zeolite raw material continuously weighs 15% of the total amount of the material through the second weighing scale 22; and continuously weighs 10% of the total amount of material through the third weighing scale 23. After being continuously mixed by the rotary mixer 3, it is prepared as MES powder raw material containing 10% Glauber's salt.

Embodiment 2

[0042] The newly ground MES raw material is put into the first silo 11; the zeolite raw material is put into the second silo 12; the Glauber’s salt raw material is put into the third silo 13; the newly ground MES first weighing scale 21 through the measuring equipment The MES raw material that continuously weighs 70% of the total amount of material; the zeolite raw material continuously weighs 15% of the total amount of material through the second weighing scale 22; the mirabilite continuously weighs 15% of the total amount of material through the third weighing scale 23. After being continuously mixed by a rotary mixer 50, the MES powder raw material composition containing 15% Glauber's salt is prepared.

Embodiment 3

[0044] The zeolite raw material is put into the first silo 11; the Glauber’s salt raw material is put into the second silo 12; the newly ground MES raw material is put into the third silo 13; the newly ground MES first weighing scale 21 is passed through the measuring equipment The MES raw material that continuously weighs 80% of the total amount of material; the zeolite raw material continuously weighs 10% of the total amount of material through the second weighing scale 22; the mirabilite continuously weighs 10% of the total amount of material through the third weighing scale 23. After being continuously mixed by a rotary mixer 50, the MES powder raw material composition containing 20% Glauber's salt is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com