High damping Mg-Sn-Ce alloy and preparation process thereof

A mg-sn-ce, high damping technology, applied in the field of multi-element magnesium alloys and their manufacturing, can solve the problems of limited, no necessary connection, and unfavorable damping performance, and achieves strong portability, low cost, and convenient control of test parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the high damping Mg-Sn-Ce alloy, the weight percentage of each component is 1.15% Sn, 0.45% Ce, less than 0.1% impurity elements, and the rest is Mg. The purity of raw materials industrially pure magnesium is greater than 99.9%, the purity of high-purity tin is greater than 99.95%, and the Mg-Ce master alloy (Mg-14.08wt%Ce) is compounded according to the above ratio. Put the three kinds of raw materials into the electromagnetic induction melting furnace for melting. During the melting process, argon is used as the protective gas. The temperature is raised to 770°C for heat preservation and electromagnetic induction stirring to make the ingredients uniform and the raw materials are fully melted. After all the raw materials are melted, cool down to 620°C and stand still. Insulated for 22 minutes, taken out and cooled in a salt bath to obtain a Mg-Sn-Ce alloy ingot.

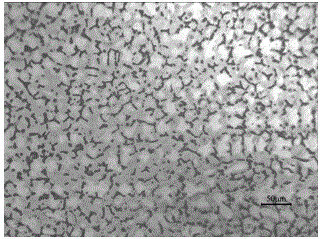

[0021] The microstructure photo of the high damping magnesium alloy is obtained as figure 2 shown.

Embodiment 2

[0023] High-damping Mg-Sn-Ce alloy, the weight percentage of each component is 3.14% Sn, 0.48% Ce, less than 0.1% impurity elements, and the rest is Mg. The purity of raw materials industrially pure magnesium is greater than 99.9%, the purity of high-purity tin is greater than 99.95%, and the Mg-Ce master alloy (Mg-14.08wt%Ce) is compounded according to the above ratio. Put the three kinds of raw materials into the electromagnetic induction melting furnace for melting. During the melting process, argon is used as the protective gas. The temperature is raised to 770°C for heat preservation and electromagnetic induction stirring to make the ingredients uniform and the raw materials are fully melted. After all the raw materials are melted, cool down to 620°C and stand still. Insulated for 22 minutes, taken out and cooled in a salt bath to obtain a Mg-Sn-Ce alloy ingot.

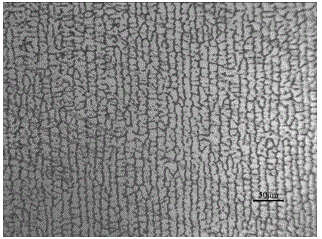

[0024] The microstructure photo of the high damping magnesium alloy is obtained as image 3 shown.

[0025] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com