Method for adjusting bivalent tin ion concentration

A technology of divalent tin ion and adjustment method, which is applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of long cycle, difficult preparation and adjustment of divalent tin ions, etc., so as to achieve short cycle and shorten the preparation and adjustment of bath solution. cycle, the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

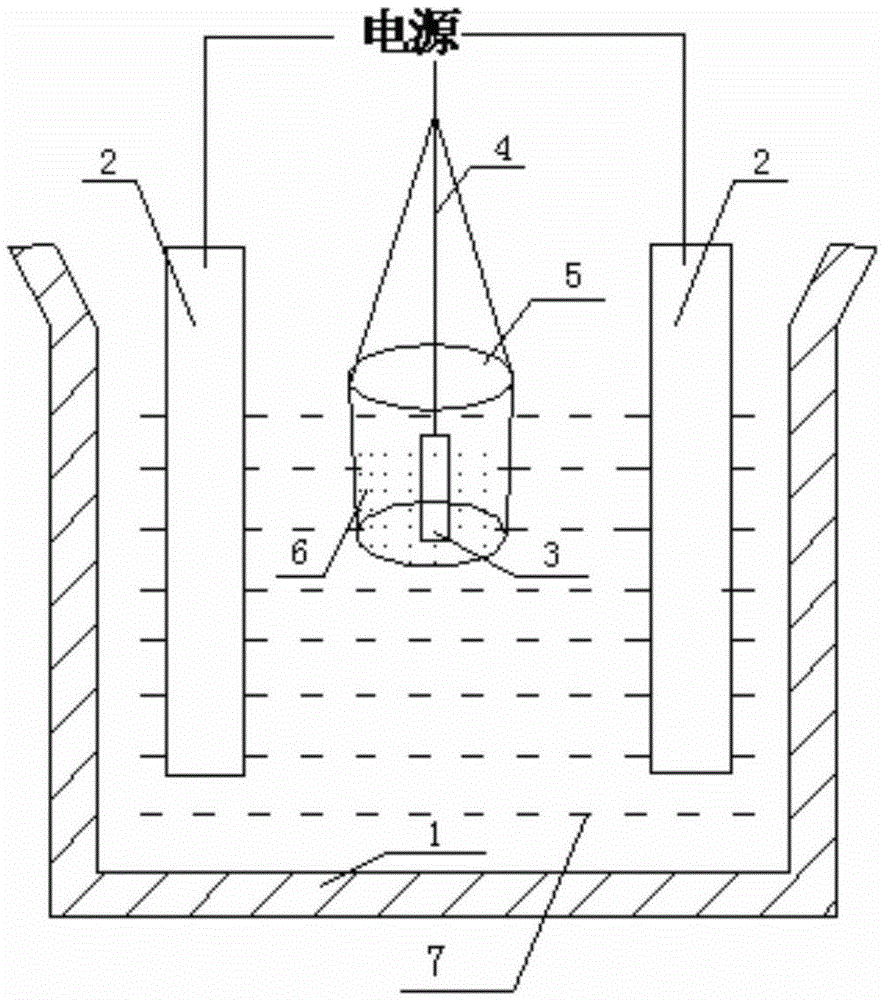

Image

Examples

Embodiment 1

[0027] Embodiment 1: Bath solution preparation

[0028] Carry out the preparation of acidic tin plating bath according to the above method, the preparation time is shortened from the original 7 days to the present 3 days, the tin ion concentration reaches the 50g / l of process requirements from 0, the bath has no sediment, no impurities, no need to filter and Parts can be directly produced by electrolysis, and the tinned parts produced meet the process requirements.

Embodiment 2

[0029] Example 2: bath maintenance

[0030] Adjust the tin ion concentration of the acidic tin plating bath according to the above method. The tin ion concentration reaches the 50g / l required by the process from 30g / l. The bath has no deposits and impurities, and the parts can be directly produced without filtration and electrolysis. And the tin-plated parts produced meet the process requirements.

Embodiment 3

[0031] Example 3: bath maintenance

[0032] Carry out the adjustment of the tin ion concentration of the acidic tin plating bath according to the above method, the tin ion concentration reaches the 48g / l required by the process from 35g / l, the bath has no deposits and impurities, and the parts can be directly produced without filtering and electrolysis. And the tin-plated parts produced meet the process requirements.

[0033] The result of the embodiment shows that the present invention can be applied to the preparation and maintenance of the acidic tin plating bath, which greatly shortens the cycle and improves the surface quality of the tin plating layer of parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com