Hollow truss compound core formwork

A technology of fasting type and truss, which is applied in the direction of building components, walls, floors, etc., and can solve problems such as prone to collapse, poor mechanical performance of pot-shaped molds, and affecting pouring of hollow floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

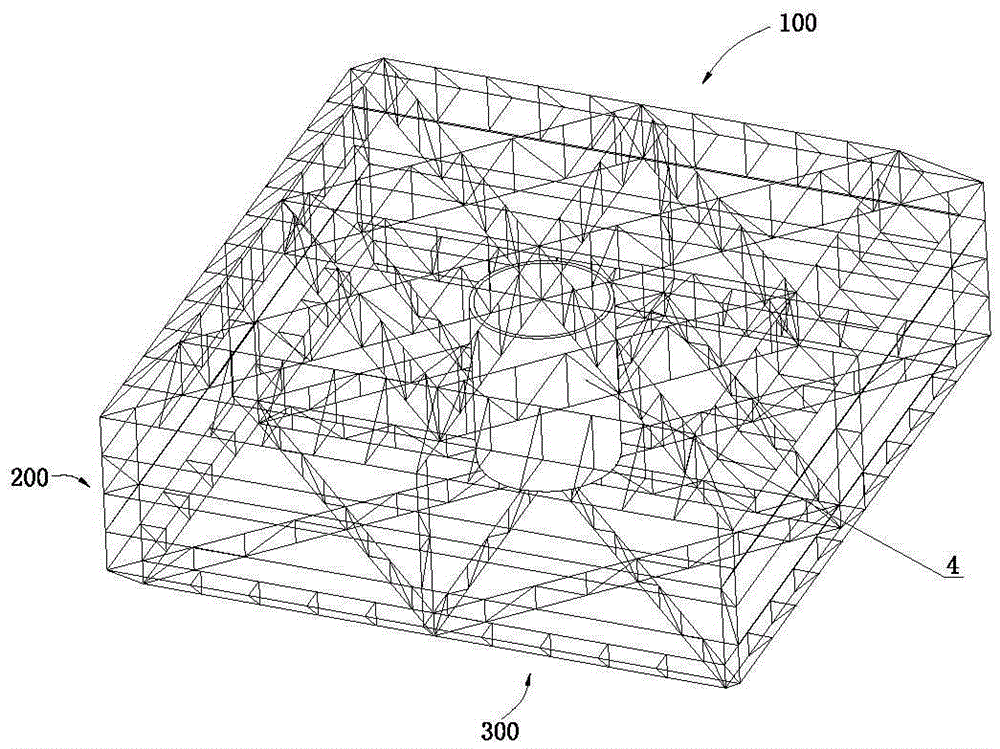

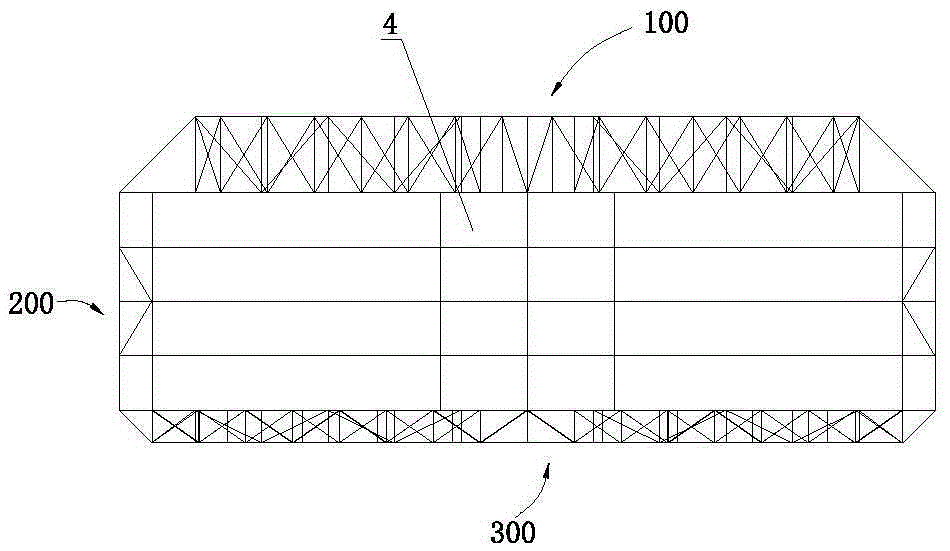

[0032] Such as Figure 1 to Figure 3 As shown, the hollow truss composite mandrel includes a flexible sleeve, an upper cover frame 100 , a lower cover frame 300 and more than one layer of intermediate support frames 200 . In this embodiment, there is one intermediate support frame 200 .

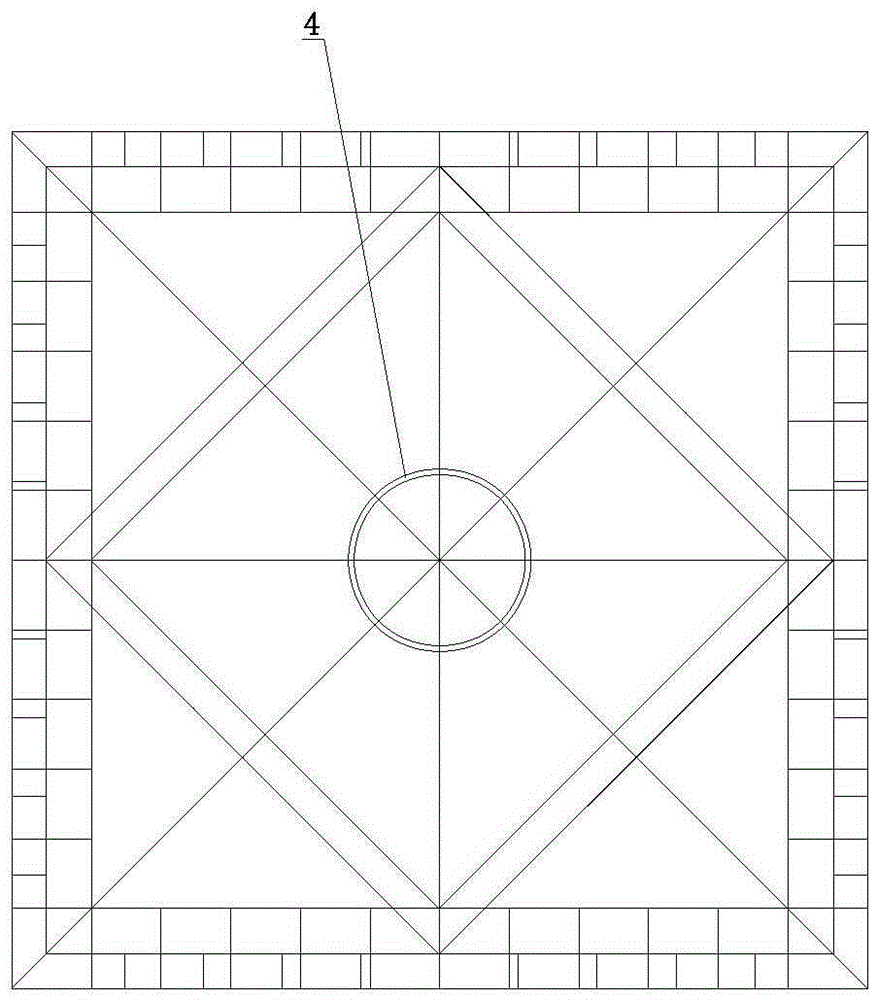

[0033] Such as figure 1 , 2 , 3 and Figure 4 As shown, the upper cover frame 100 is a truss structure. The upper cover frame 100 includes an upper cover outer frame 101 and an upper horizontal tension truss 102 , the upper horizontal tension truss 102 is located in the upper cover outer frame and connected with the upper cover outer frame 101 .

[0034] The upper cover outer frame 101 is surrounded by a plurality of upper side beam trusses 1 connected to each other. Such as Figure 4 As shown, the roof sill truss 1 includes more than two roof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com