Pipe-free pump

A tubeless pump and pump body technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems that the motor cannot be disassembled and repaired, the massage effect is not ideal, and the process is complicated, so as to simplify the production assembly process and improve the massage effect Good, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

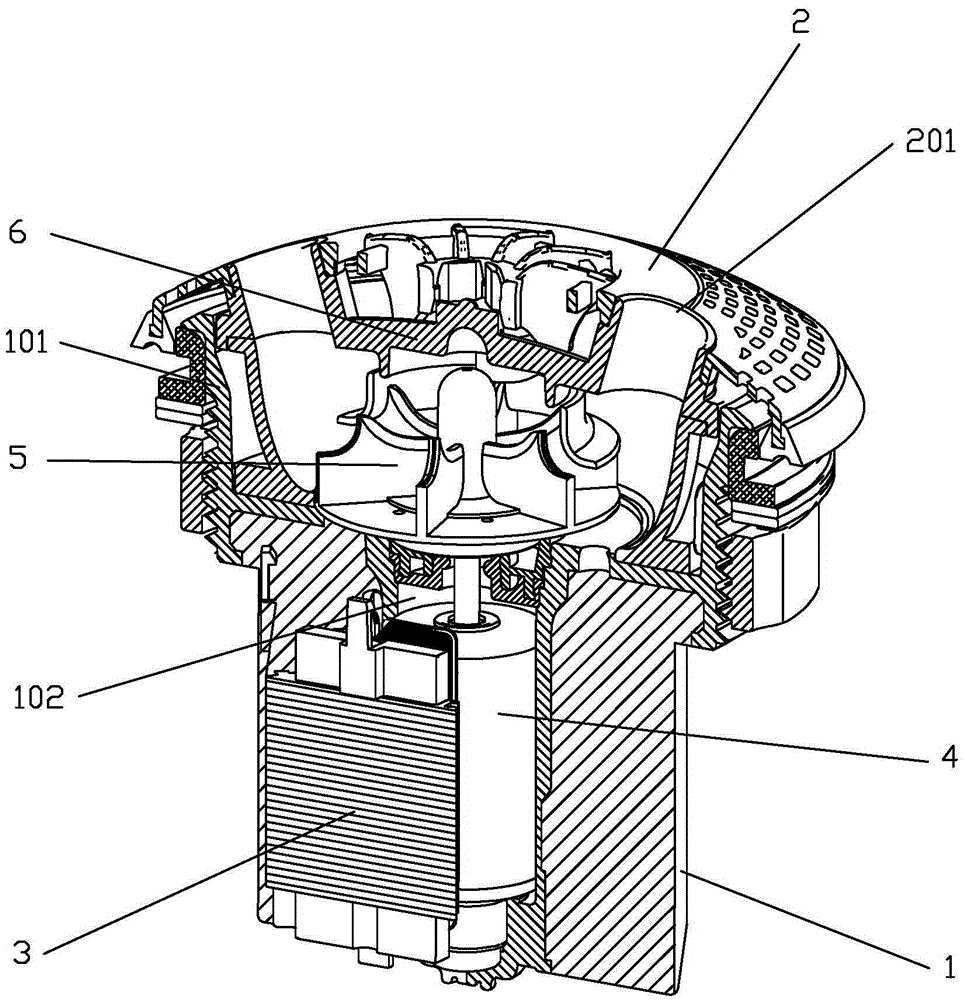

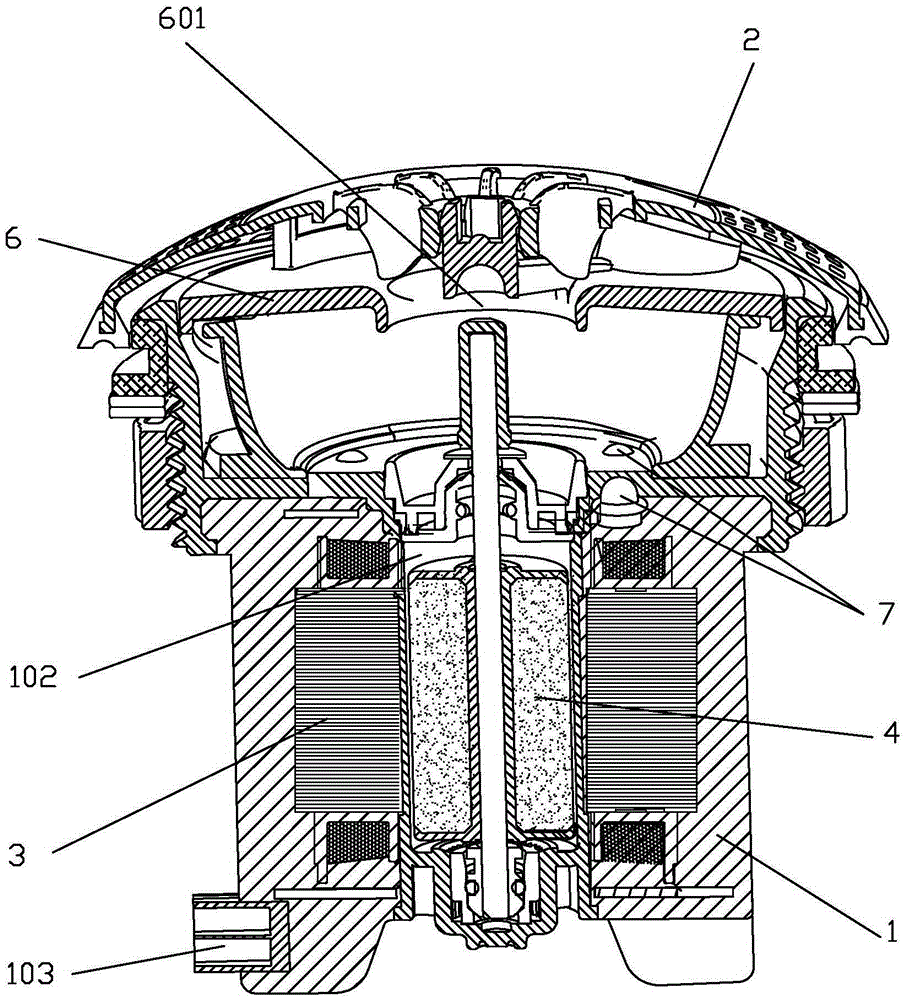

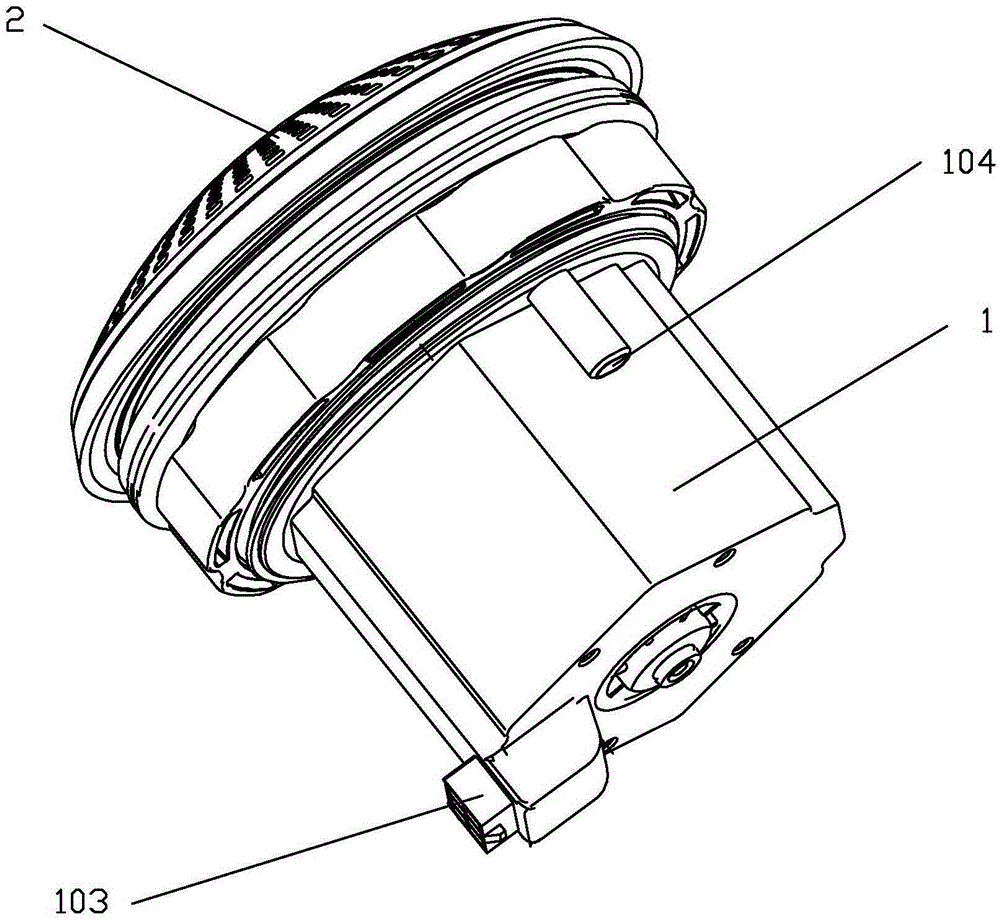

[0024] refer to Figure 1~Figure 8 , a tubeless pump, including a pump body 1 and a front cover 2 connected to the pump body 1, a stator 3 and a rotor 4 are arranged inside the pump body 1, and an impeller 5 is installed on the rotating shaft of the rotor 4, so The pump body 1 includes a casing integrally injection-molded around the outline of the stator 3 and a mounting portion 101 formed by secondary injection molding at the front end of the casing for connecting the front cover 2 and an accommodating cavity for accommodating the rotor 4 102, the installation part 101 is provided with a water guide cover 6, the water guide cover 6 is provided with a water inlet 601 in the center and a water outlet 602 on the side of the water inlet 601, and the impeller 5 is arranged on the water guide Inside the cover 6 , the front cover 2 is provided with a water spray port 201 corresponding to the water outlet 602 . The pump body 1 is formed by two injection moldings, the first time cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com