Compass Riser Hanger

A technology of riser and hanger, which is applied in the direction of pipeline support, pipeline protection, pipeline protection through heat insulation, etc. It can solve the problems of heavy welding and heat treatment workload, high consumption of alloy steel, unsafe suspension rod unloading, etc. Achieve the effects of facilitating component stress analysis, eliminating heat treatment, and reducing the cost of hanger materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

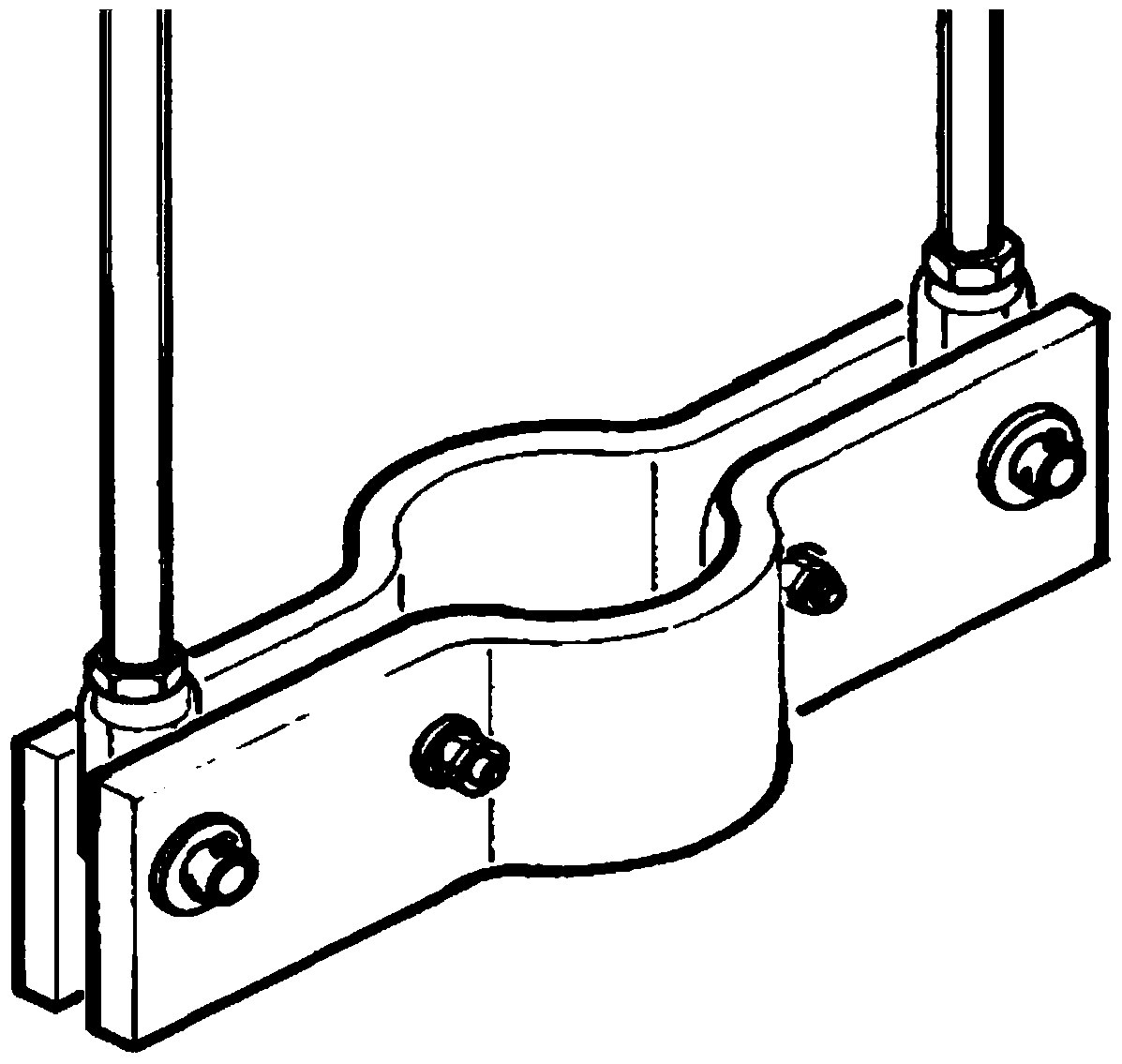

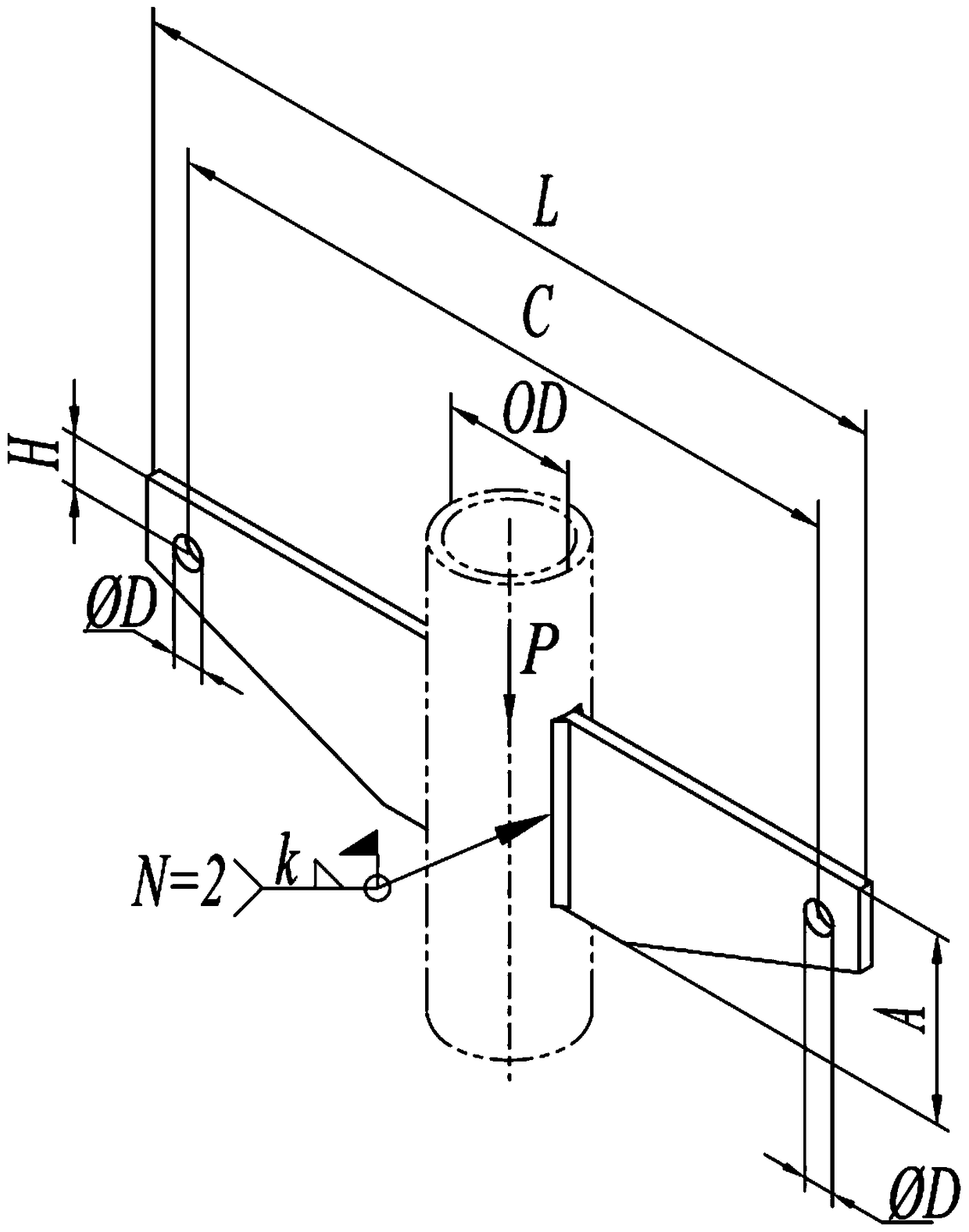

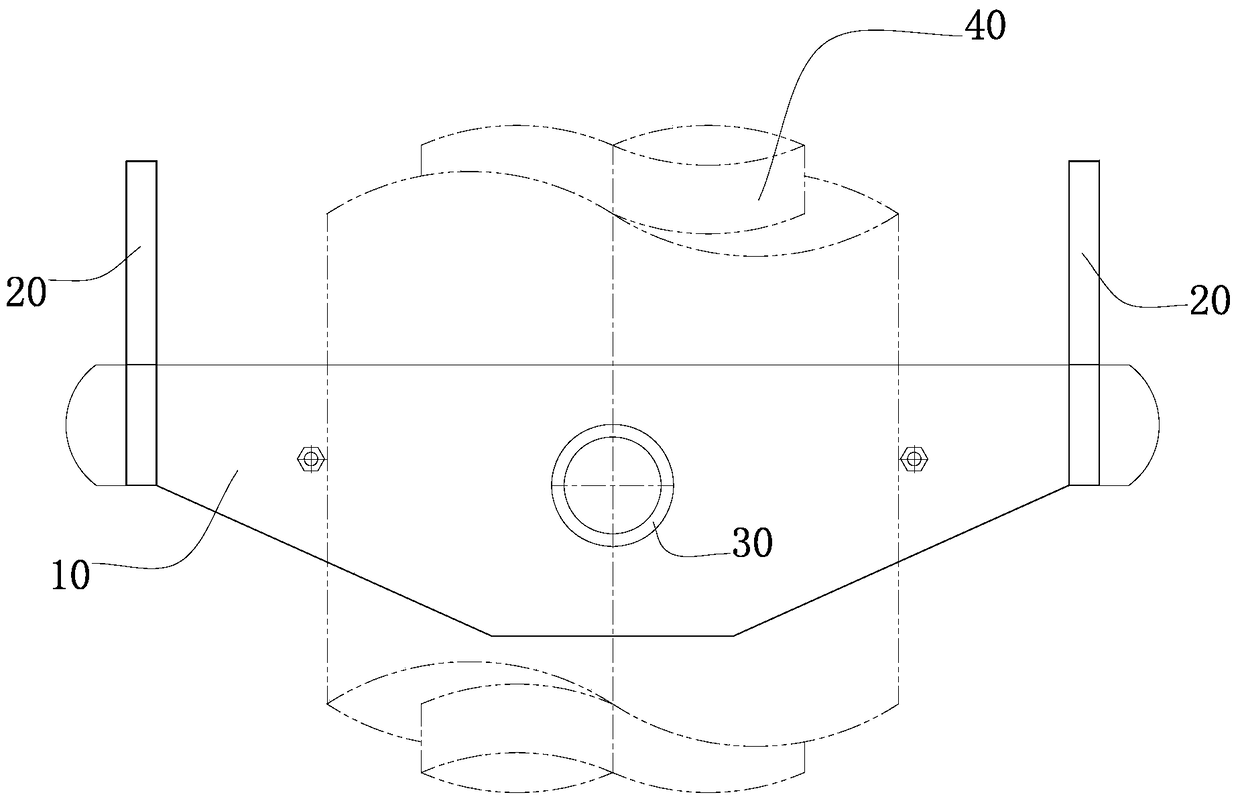

[0033] The compass type standpipe hanger of the present invention usually includes side plates, hanging plates and trunnions, one end of the trunnion is welded on the outer wall of the standpipe, the other end of the trunnion is connected with the side plate, and the side plate is arranged on the side wall of the standpipe. Outboard and connected to the hanger plate, the hanger plate is connected to the hanger connection and / or the hanger function. In use, the riser transfers the load to the trunnion, the trunnion transfers the load to the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com