Experimental device and method for the whole process of concrete water cooling

A technology of water cooling and testing equipment, which is applied in the direction of measuring equipment, material inspection products, and the use of stable tension/pressure to test the strength of materials, etc., to achieve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

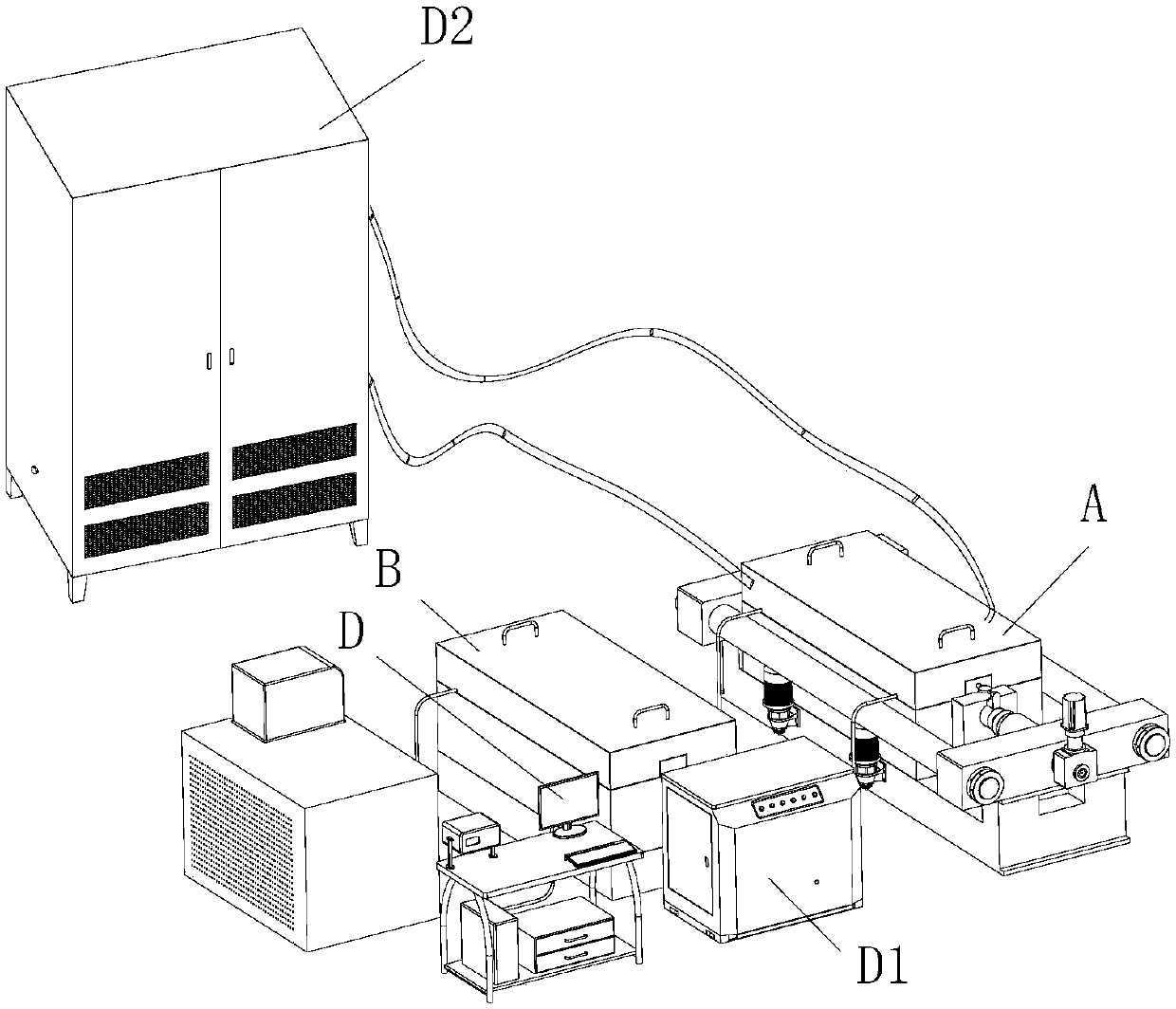

[0161] The whole process test device for concrete cracking based on real environment provided by the present invention is such as figure 1 As shown, it includes a main testing machine A and an auxiliary testing machine B. There is also a computer D, which is connected to a control system D1 and a water cooling simulation system control system D2 through a data line. The control system D1 includes:

[0162] 1. The control units of the main testing machine A and auxiliary testing machine B that control various actuators of the real environment simulation system;

[0163] 2. The control unit of the actuator that controls the loading of the concrete specimen in the main testing machine A is the control unit of the power device in the loading system.

[0164] The control system D2 includes: the control unit of each actuator in the water cooling simulation system D2 in the main testing machine A that controls the temperature of the concrete specimen.

[0165] The data line of computer D is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com